33

33

3

BLuAC5 Hardware ManualBLuAC5 Hardware Manual

BLuAC5 Hardware ManualBLuAC5 Hardware Manual

BLuAC5 Hardware Manual

ContentsContents

ContentsContents

Contents

Safety Instructions ................................................................................................. 5

Introduction ......................................................................................................... 6

Block Diagram...................................................................................................................6

Getting Started ..................................................................................................... 7

Status & Error Display LEDs ....................................................................................... 9

Serial Comm Tx & Rx LED ......................................................................................... 9

Bus voltage indication LED ......................................................................................... 9

Seven Segment Display Error codes .......................................................................... 9

Seven Segment Display Status codes ...................................................................... 10

Regeneration LED .................................................................................................... 10

Connecting to the PC using RS-232 ............................................................................ 11

Connecting to a host using RS-485 ............................................................................. 12

A Short tutorial on RS-485 & RS-422 .............................................................................. 12

4-wire RS-485/422 Network...................................................................................... 13

Getting and Connecting a RS-485 4-wire adaptor to your PC................................... 13

2-wire RS-485 Network............................................................................................. 14

Getting and Connecting a RS-485 2-wire adaptor to your PC................................... 14

BeforeYou connect the servo drive to your system -................................................. 14

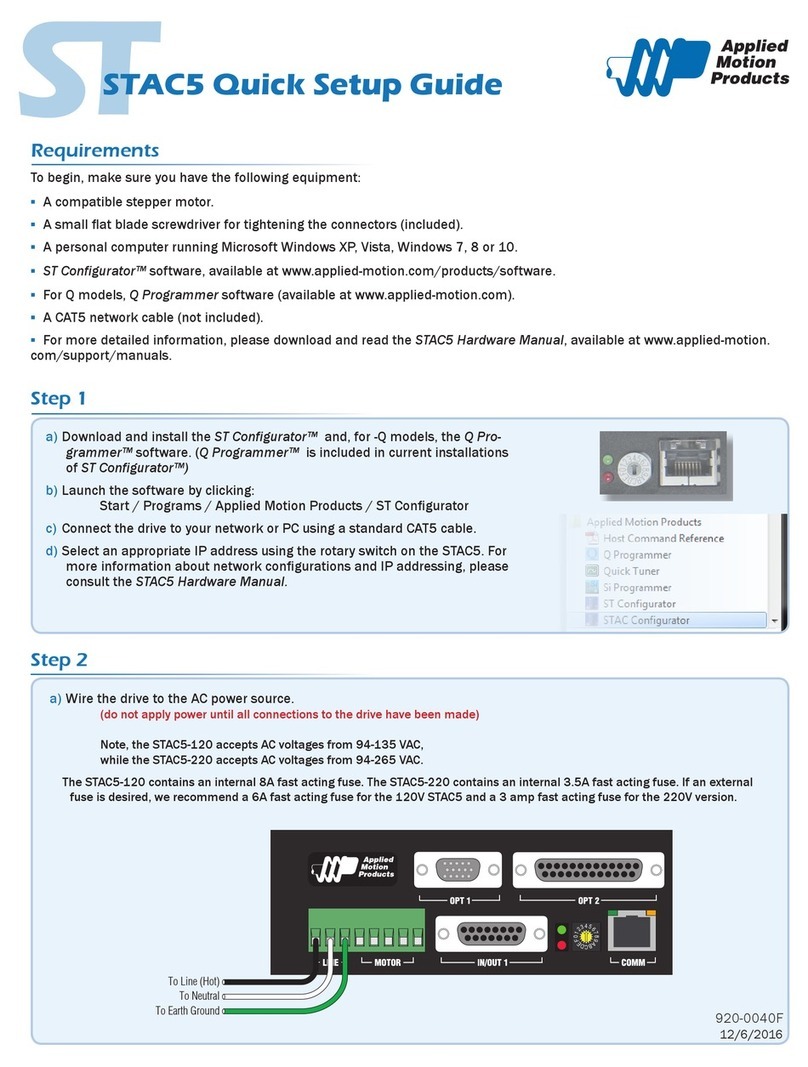

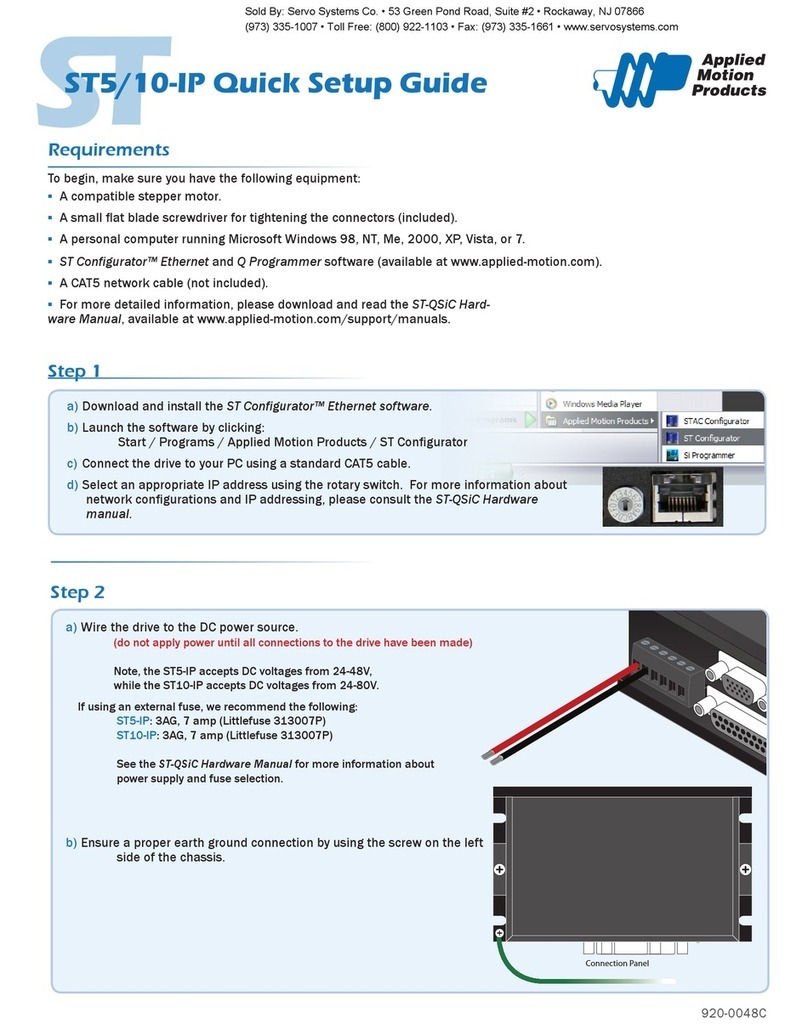

Connecting the AC Power Input ................................................................................. 15

24Volt Controller Input (Keep Alive).......................................................................... 15

Connecting Single Phase AC input (90-260VAC) ............................................................ 16

Connecting 3-Phase AC input (90-260VAC).................................................................... 16

Connecting DC input (100-367VDC) .............................................................................. 16

Connecting the Motor ............................................................................................ 17

Connecting the Encoder & Hall Sensors ....................................................................... 18

Encoder Pinout ......................................................................................................... 18

Connecting a Single-Ended Encoder ........................................................................ 18

Connecting Single-Ended Hall Sensors .................................................................... 18

Connecting Input Signals ........................................................................................ 19

IN/OUT 1 I/O Connector ........................................................................................... 19

With Expanded I/O (IN/OUT 2) ................................................................................. 19

IN/OUT1 & IN/OUT 2 Connector Pinout Diagrams .................................................. 19

High Speed Digital Inputs................................................................................................ 20

Using High Speed Inputs with 12-24Volt Signals...................................................... 20

Using Mechanical Switches at 24Volts. .................................................................... 21

Connecting to PLC with Sourcing (PNP) Outputs ..................................................... 21

Connecting to PLC with Sinking (NPN) Outputs ....................................................... 21

Standard Digital Inputs ........................................................................................... 22

Single Ended Inputs ........................................................................................................ 22

What is COM? .......................................................................................................... 22

User Out 24V supply................................................................................................. 22

Digital Input Connection Examples ........................................................................... 23

Connecting Limit Switches to the BLuAC5 Drives ........................................................... 24

BLuAC5Limit Input diagram ..................................................................................... 24

Wiring a Mechanical Limit Switch.............................................................................. 24

Wiring a Limit Sensor................................................................................................ 24

Analog Inputs ...................................................................................................... 25

Three dedicated purposes: ....................................................................................... 25

Basic Specifications:................................................................................................. 25

Wiring a controller with differential output as a single ended input ........................... 26

Wiring a controller with differential output to differential input................................... 26

Wiring a potentiometer to a single ended input ........................................................ 26

Programmable Outputs ........................................................................................... 27

Encoder Outputs ............................................................................................................. 28