TECHNOPOOL

Dosing systems for swimming pools ENGLISH

ADSP7000570 rev. 2.0 06/08/2021 2/37

CONTENTS

1.0 INTRODUCTION ..............................................................................................................................................3

1.1 Warnings.......................................................................................................................................................3

1.2 Conformity.....................................................................................................................................................4

1.3 Technical features.........................................................................................................................................4

1.4 Electrical features .........................................................................................................................................4

1.5 Packaging content ........................................................................................................................................4

2.0 INSTALLATION ................................................................................................................................................5

2.1 Wall mounting...............................................................................................................................................5

2.2 Electrical connections...................................................................................................................................5

2.2.1 Main power supply................................................................................................................................5

2.2.2 Temperature probe...................................................................................................................................5

2.2.3 Flow signal................................................................................................................................................5

2.2.4 Dosing enabling signal (V1)......................................................................................................................5

2.2.5 P1 pump product level probe (only for technopool3)................................................................................5

2.2.6 pH pump product level probe....................................................................................................................5

2.2.7 P2/Rx/Cl/HP pump product level probe....................................................................................................6

2.2.8 Alarm output –24V OUT Clamp...............................................................................................................6

2.2.9 Solenoid valve output –RELAY Clamp...................................................................................................6

2.2.10 Pump switches......................................................................................................................................6

2.3 Hydraulic connections.........................................................................................................................................7

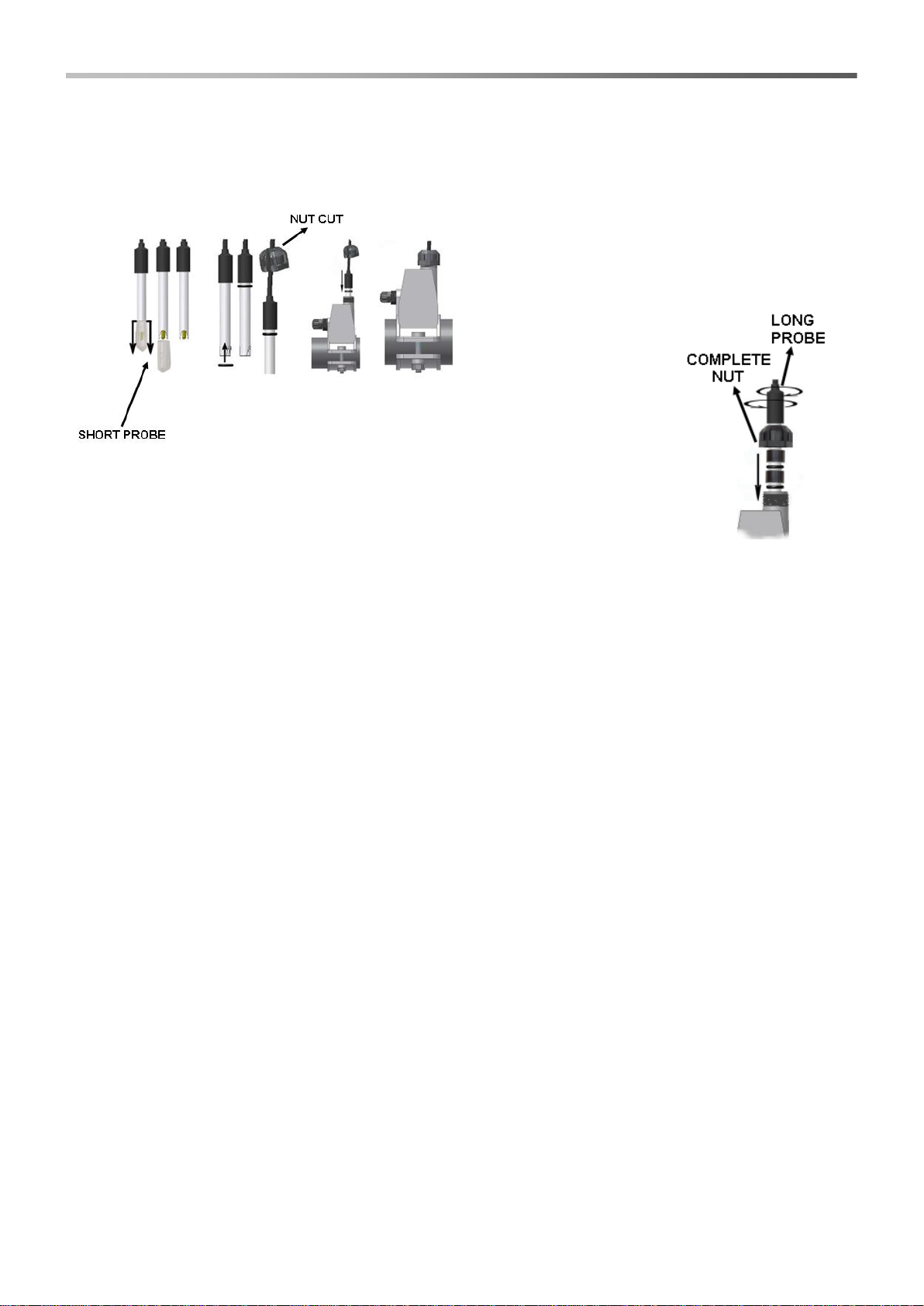

2.3.1 Assembly of the accessories........................................................................................................................7

3.0 TECHNOPOOL MENU.....................................................................................................................................9

3.1 User Menu ..................................................................................................................................................10

3.1.1 Manual activation of pumps and solenoid valve.....................................................................................11

3.2 Installer menu .............................................................................................................................................12

3.2.1 Password insertion..................................................................................................................................12

4.0 QUICK PROGRAMMING ...............................................................................................................................13

4.1 Selection of the language of the system.....................................................................................................13

4.2 Setting the temperature ..............................................................................................................................13

4.3 Setting of the cyclic dosing (pump P1) –it is not displayed on pH/Rx, pH/ClJ and pH/HP technopool3...13

4.4 Setting the pH (pump pH)...........................................................................................................................15

4.5 Setting the redox (P2 pump).......................................................................................................................16

4.6 Setting the chlorine probe (pump P2).........................................................................................................17

4.6.1 Setting the chlorine (pump P2) ...............................................................................................................17

4.7 Setting the hydrogen peroxide probe (pump P2)........................................................................................18

4.7.1 Setting the hydrogen peroxide (pump P2)..............................................................................................18

4.8 Setting the cyclic dosing ( pump)................................................................................................................19

4.9 Setting the solenoid valve...........................................................................................................................20

4.10 Calibration of pH electrode .........................................................................................................................22

4.11 Calibrating the redox electrode...................................................................................................................22

4.12 Calibrating the chlorine electrode...............................................................................................................23

4.13 Calibrating the hydrogen peroxide electrode..............................................................................................23

5.0 ADVANCED PROGRAMMING.......................................................................................................................25

5.1 Configuration of the settings.......................................................................................................................25

5.2 Restore the default parameters..................................................................................................................26

6.0 ALARMS .........................................................................................................................................................26

6.1 Setting the alarms.......................................................................................................................................26

6.2 Alarm signal................................................................................................................................................27

7.0 WINTER PAUSE.............................................................................................................................................27

8.0 OPERATIONS TO CARRY OUT AT THE BEGINNING OF THE SEASON ..................................................27

9.0 RETURN TO THE AFTER-SALES SERVICE................................................................................................28

10.0 GUARANTEE CERTIFICATE.....................................................................................................................28

11.0 APPENDIX 1 –Default parameters................................................................................................................29

12.0 APPENDIX 2 –TECHNOPOOL RANGE .......................................................................................................30

13.0 APPENDIX 3 –FREE CHLORINE MEASURE CELL (CL) ............................................................................31

14.0 APPENDIX 4 –HYDROGEN PEROXIDE MEASURE CELL (HP).................................................................33

ESPLOSO / EXPLODED VIEW / EXPLOSE / DIBUJO..............................................................................................35