B-KALK4us.DOC, Seite 2, Aug. 11

Instruction manual of AquaCare

Turbo Chalk Reactor – Ca-Reactor

Principe of the Turbo Chalk Reactors

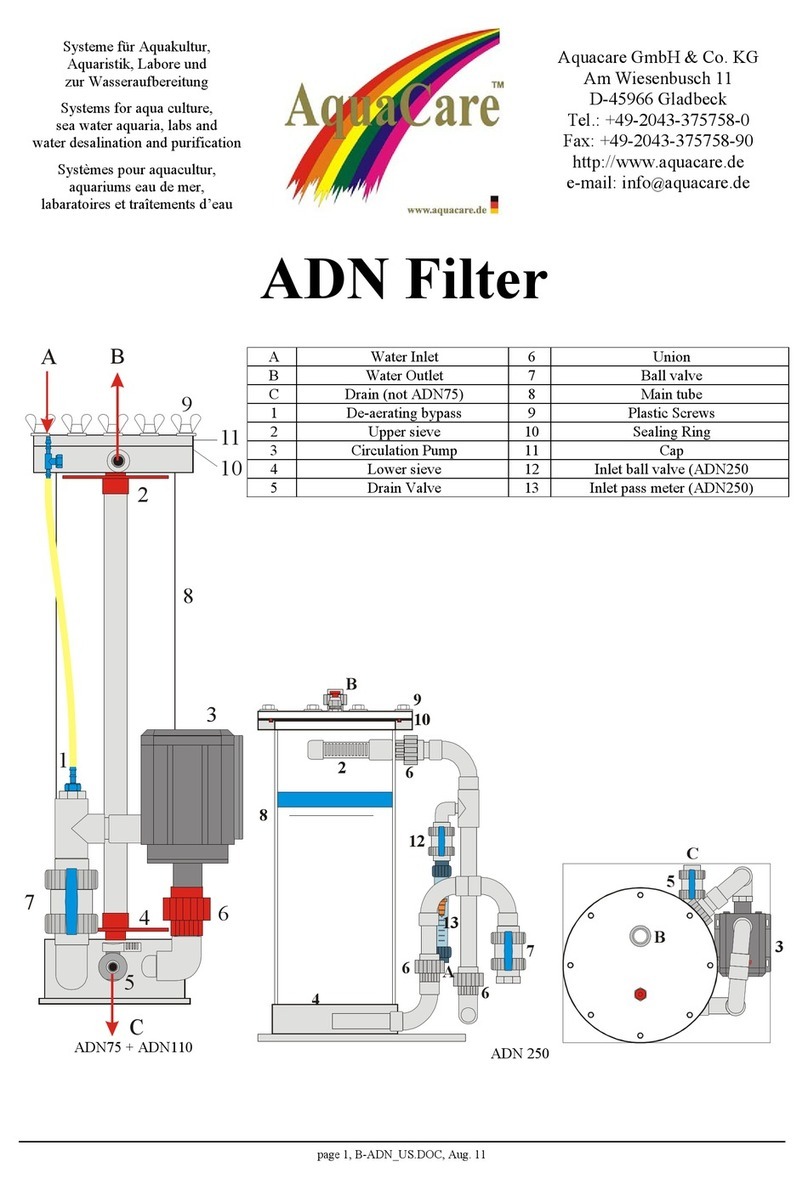

In the CO2tube (1) CO2is dosed to lower the pH of the water

(about 5,2 to 5,5). The circulation pump (8) pumps the water into

the next tube - the calcite tube (2). In this compartment the calcite

material is dissolved. The calcite is split into calcium and hydrogen

carbonate (alkalinity). The enriched water flows back to the CO2

tube (1)- the cycle is closed.

The same volume of incoming water flows out of the system - you

can see in inflow in the small transparent tube (6) above the CO2

tube. The volume is controlled with the small ball valve (5). The

outflow reaches the neutralizing tube (3). In this compartment air

strips out the CO2(about 80%) with the help of an air stone (12).

The neutralized water flows to the sediment tube (4). Most of the

very fine sediment, caused by friction in the calcite tube, sinks

down on the bottom of the sediment tube. In this tube small amounts

of phosphate adsorbs (chemo sorption) at the sediments.

Mounting the unit

Best place for the reactor:

The Turbo Chalk Reactor must be mounted vertically to guarantee

the function. Please use the screws (in the plastic bag) to fix the re-

actor at a wall (stone or wood). If you have another wall please use

special plugs.

The AquaCare Turbo Chalk Reactor should be mounted in the near

of the aquarium or filter tank. The water outlet hose must be fixed in

a slope – the hose never should go uphill to the tank. Therefore the

sediment tube must be higher than the aquarium or filter tank. You

may mount the sediment tube away from the reactor for assemble

the tube to the aquarium downhill. But please consider, that you

need a stronger air pump for the neutralizing tube (each meter you

need 100 mbar more pressure). Additionally you must take a longer

hose from the neutralizing tube to the sediment tube.

Additionally you need an electrical connection in the near (within 2

meters). The best place is a dark place. If the reactor is in the sun

you have to cover a black foil around the transparent tubes to pre-

vent algae growth.

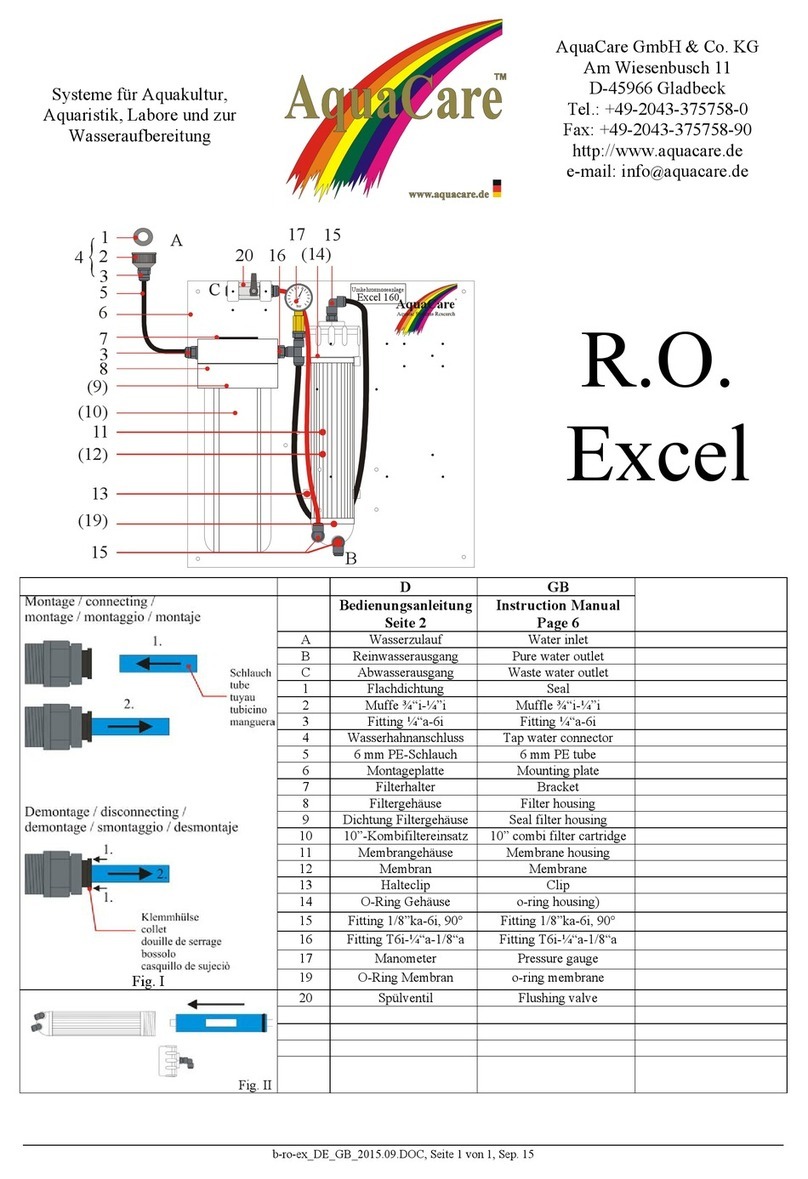

Connection of the hoses (see Fig. II):

For mounting the hoses cut them with a sharp knife. For the push fit

fittings only use the black AquaCare PE hose/tube. Otherwise use

the connectors to other hoses (PVC or silicone).

The pressure hose is pushed into the push fit fitting until it cannot

be pushed further. The tube should be gently pulled to ensure that

the connection is sound. The connection can be released by pushing

back the collet and pulling the tube out.

Water Outlet: (see Fig. I)

The water outlet (B) of the reactor will be made with the 10mm

hose. Please take care to assemble the hose downhill from reactor to

tank/aquarium. If not the water will flow out off the reactor (C). The

hose must end over the water level! To prevent turbid water in the

aquarium caused by very fine sediments you can direct the water to

a sediment filter filled with fine material, e.g. filter floss. You may

assemble the air outlet (C) parallel to the water outlet hose – if the

water outlet hose is blocked the water will flow through the air

hose. The air hose should never be under the water level! Otherwise

the CO2in the air will lower the pH of the aquarium water and bub-

bling sound will occur.

Water Inlet: (see Fig. III)

You can realize the water inlet (A) with an extra circulation pump

or with a bypass from the main circulation pump that pumps the wa-

ter from the filter tank to the aquarium. The pump must have

enough pressure; the water flow does not matter. The best solution

is a bypass: you do not need an extra pump and the water from a

bypass contains less sediments that are able to block the water inlet

valve. A water pass meter (option) is a very easy way to regulate the

right water inflow. The water inlet (A) of the AquaCare Turbo

Chalk reactor is at the top of the CO2tube (1). You can see the in-

flowing water at the inspection glass (6). Turbo Chalk reactors with

built in water pass meters must be supplied at the bottom of the pass

meter. If you do not use the original AquaCare PE hoses you can

use the hose adapter (packed in the plastic bag). If you have ques-

tions or problems with the connections please ask AquaCare.

CO2supply: (see Fig. IV)

For operation the Turbo Chalk reactor needs a CO2supply, too.

Please use CO2pressure tanks – other systems with pressures below

0,5 bar (7 PSI) will not work properly. Please read the instruction

manual for the pressure tank and pressure relief valve care-

fully! The pressure of the pressure relief valve should be between

0,5 and 2 bar (7 and 30 PSI). Never raise the pressure above 5 bar

(45 PSI)! Never work without a GOOD check valve (check valves

for air are not suitable!). Back flowing water will destroy solenoids

and pressure relief valves. Please assemble the CO2hose with a se-

curity loop with minimum 1 meter.

Air supply for neutralizing tube:

The air inlet (D) is at the top of the neutralizing tube (3). Assemble

the air hose with a security loop of minimum 1 meter, too. Check

valves normally reduce the air pressure drastically and they will not

work 100%ly. Back flowing water will destroy the air pump. If the

pH of the out coming water is below 7,0 the air pump is to weak! In

that case use a stronger air pump.

Electrical connection:

For operating the Turbo Chalk reactor you need an electrical supply

and a simply timer. Please control the voltage of the electrical com-

ponents (pump, Chalk reactor control) with the voltage of the sup-

ply! Connect the Turbo Chalk reactor pump and the Turbo Chalk

rector control unit to the timer. Air inlet and water inlet should run

all the time.

For optimal efficiency please program the timer with a short brake

after two hours. In the break time all foreign gases like oxygen and

nitrogen will go out off the reactor.

The probe connector (9) is for installing a pH sensor. It will meas-

ure the pH of the internal water. The pH should be about 5.0 to 5.5.

Putting into operation

Please read this part carefully to prevent work and failures. In-

correct use of the reactor may destroy the circulation pump.

1. Be sure that all inlets and outlets are connected (incoming water,

out coming water, air and CO2)

2. Start the water inlet pump, open the water inlet ball valve (5) and

fill the reactor completely with water. Put the Turbo Chalk Reactor

circulation pump (8) into operation for a short time to bring out the

air off the pump. This step is important to minimize the work.

Only if all air is out of the pump it can produce the pressure for the

calcite bed. Maybe you have to wait for half a minute and start the

pump again. If all air is out off the system, stop the pumps and drain

the reactor half.

3. Open the calcite tube (2). Unscrew the cap of the calcite tube and

take out the filter sponge (11).

4. Fill up the calcite tube to the maximum filling mark (upper edge

of the label). Do not use more or another material. Otherwise the

system does not work correctly. Close the calcite tube - don’t forget

the filter sponge (11)! Please use AquaCare Turbo Granules – it is

the most effective material. With others the efficiency will fall

down.

5. Open the water inlet ball valve (start the incoming pump) and fill

the reactor with water completely.

6. If water reaches the sediment tube (4) put the circulation pump

(8) in operation. The ball valve (13) at the CO2tube should be open.

7. Reduce the ball valve at the CO2tube that only the very small

Turbo Granules will be in motion. Heavy movements of the Gran-

ules will cause turbidity in the aquarium.