Page 5

CONTROL VALVES

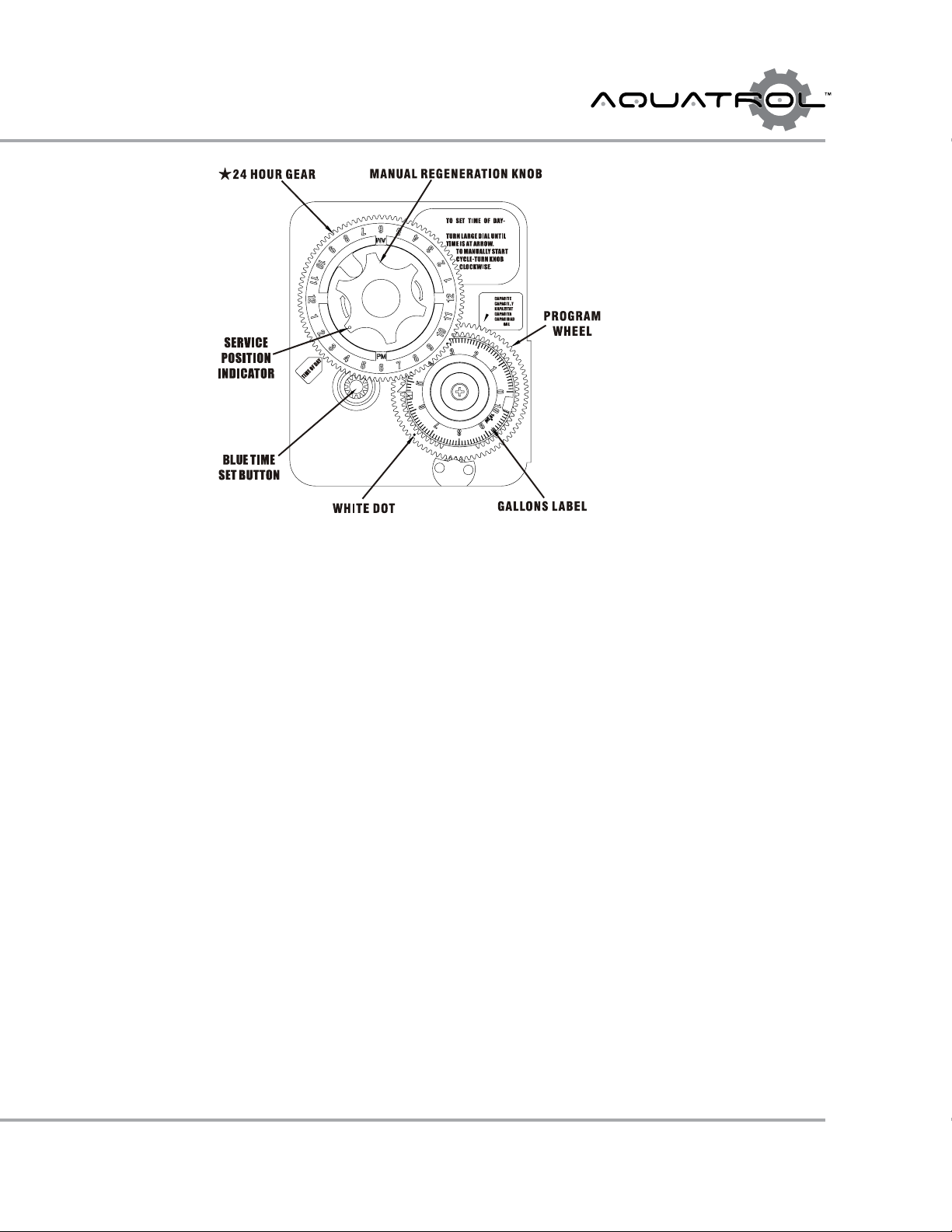

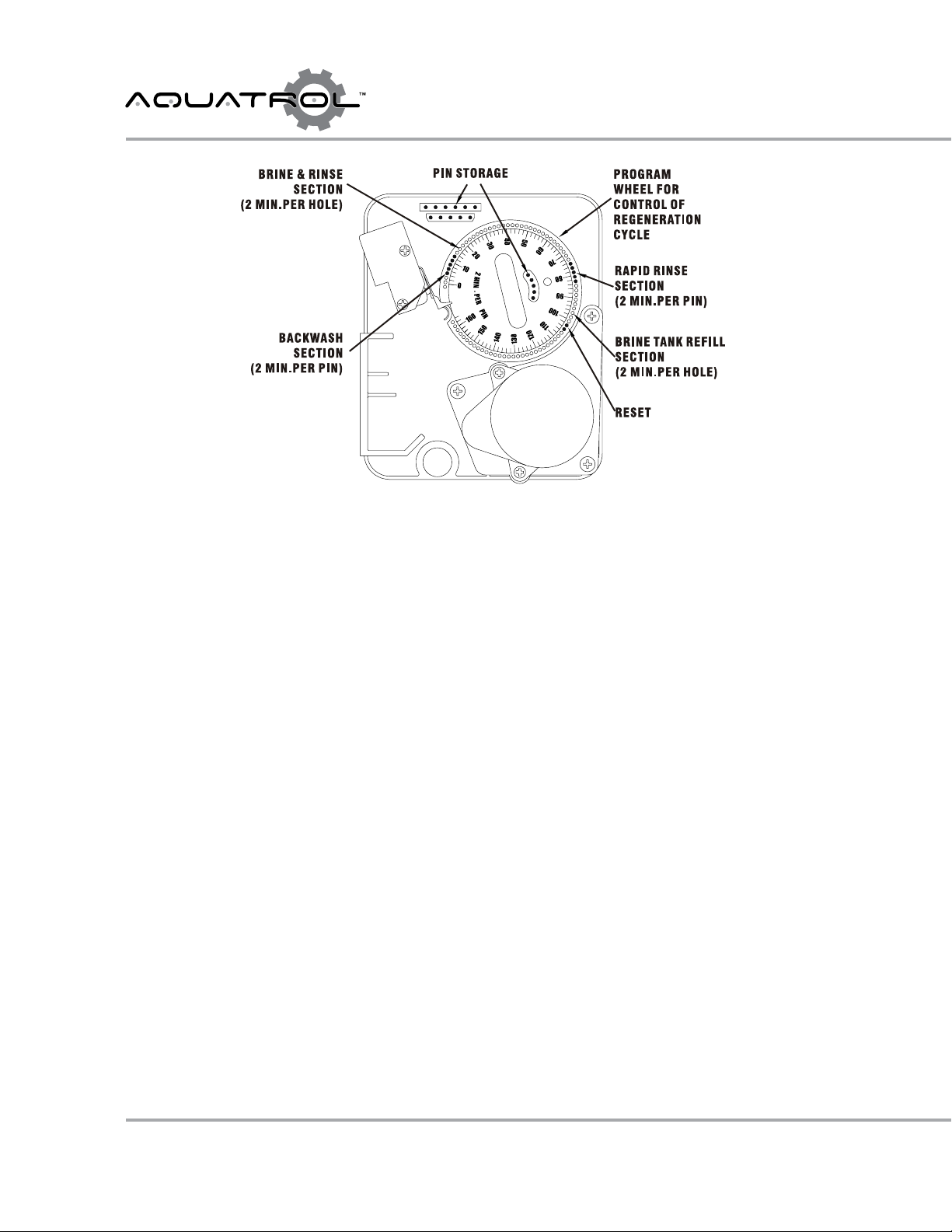

AQT-290 Timer

Start-up Setting Procedures

How To Set Days On Which Water Conditioner Is To

Regenerate:

Rotate the skipper wheel until the number "1" is at the red pointer.

Set the days that regeneration is to occur by sliding tabs on the

skipper wheel outward to expose trip ngers.

Each tab is one day. Finger at red pointer is tonight.

Moving clockwise from the red pointer, extend or retract ngers to

obtain the desired regeneration schedule.

How To Set The Time Of Day:

Press and hold the blue button in to disengage the drive gear.

Turn the large gear until the actual time of day is at the time of day

pointer.

Release the blue button to again engage the drive gear.

How To Manually Regenerate Your Water Condi-

tioner At Any Time:

Turn the manual regeneration knob clockwise.

This slight movement of the manual regeneration knob engages

the program wheel and starts the regeneration program.

The black center knob will make one revolution in the following

approximately three hours and stop in the position shown in the

drawing.

Even though it takes three hours for this center knob to complete

one revolution, the regeneration cycle of your unit might be set

only one half of this time.

In any event, conditioned water may be drawn after rinse water

stops owing from the water conditioner drain line.

How To Adjust Regeneration Time:

1. Disconnect the power source.

2. Locate the three screws behind the manual regeneration knob

by pushing the blue button in and rotating the 24 hour dial

until each screw appears in the cut out portion of the manual

regeneration knob.

3. Loosen each screw slightly to release the pressure on the time

plate from the 24 hour gear.

4. Locate the regeneration time pointer on the inside of the 24

hour dial in the cut out.

5. Turn the plate so the desired regeneration time aligns next to

the raised arrow.

6. Push the blue button in and rotate the 24 hour dial. Tighten

each of the three screws.

7. Push the blue button and locate the pointer one more time to

ensure the desired regeneration time is correct.

8. Reset the time of day and restore power to the unit.