Water Treatment Systems Limited Product Warranty

STATEMENT OF LIMITED PRODUCT WARRANTY

Limited Warranty Coverage

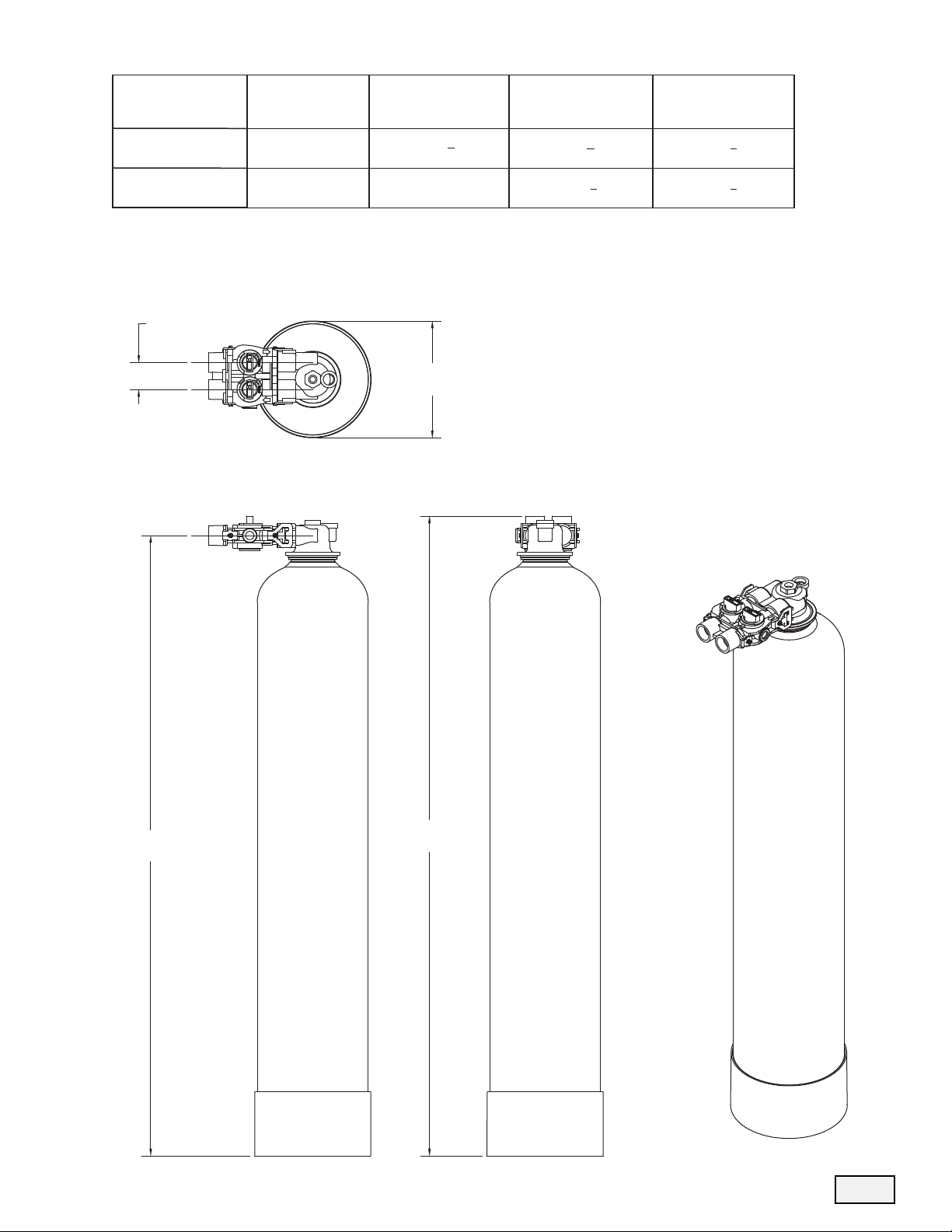

For ProSystems NRVWhole House Filters. The products are warranted to be free from defects in material and/or workmanship

under normal use and service for the following:

The Resin/Media tank, will carry a ten (10) year warranty from the date of shipment. The valve body will also carry a (10) year war-

ranty. The Media will carry a three (3) year warranty on municipal water, and a one (1) year warranty on well water. Any replace-

ment product(s) provided by ProSystems Water Treatment Systems pursuant to this Limited Warranty will be warranted only for the

remainder of the original limited warranty period or thirty (30) days from the date of shipment, whichever is longer.

The following are specifically excluded from the Limited Warranty coverage provided herein:

• Defects or problems not reported to ProSystems Water Treatment Systems during the applicable warranty period.

• Any products manufactured by other companies that are used in connection with ProSystems Water Treatment Systems product.

• Problems resulting from the alteration, modification, misuse, abuse, neglect, improper care, maintenance or negligent use,including

but not limited to unprotected outdoor installation of any ProSystems Water Treatment Systems product.

Procedure for Obtaining Limited Warranty Coverage

In order to obtain the benefits of this Limited Warranty, defective part(s) and/or product(s) must be returned to ProSystems Water

Treatment Systems as soon as possible after discovery of the defect, but not later than the expiration date of the warranty period

provided in this Limited Warranty. The Technical Service Department at ProSystems Water Treatment Systems will issue a Warranty

Return Authorization (WRA) number for the defective part(s) or product(s) which must be clearly marked on the outside of the pack-

age being returned. Packages must be shipped freight prepaid, along with a letter stating the part number, serial number, if any, the

date of purchase of the item which is claimed to be defective and a brief description of the problem detected. ProSystems Water

Treatment Systems is not responsible under this Limited Warranty for any cost incurred for shipping or transportation in connection

with the return of the part(s) or product(s).

Repair or Replacement

Upon receipt of the product and warranty claim, ProSystems Water Treatment Systems will verify the reported failure and determine

if the part(s) or product(s) is/are covered by this Limited Warranty. If this Limited Warranty applies, ProSystems Water Treatment

Systems will, at its option, repair or replace the part(s) or product(s).

No Liability for Consequential Damages

Unless otherwise required by applicable law, ProSystems Water Treatment Systems shall not be liable for any damages whatsoever

(including without limitation, loss time, inconvenience, expenses such as telephone calls, labor or material charges incurred in con-

nection with the removal or replacement of the part(s) or product(s), special, incidental, consequential, or indirect damages for per-

sonal injury, loss of business profits, business interruption, loss of business information, or any other pecuniary loss) arising out of

the use of or inability to use the defective part(s) or product(s), even if ProSystems Water Treatment Systems has been advised of

the possibility of such damages. ProSystems Water Treatment Systems entire liability under any provision of this Limited Warranty

shall be limited to the amount actually paid for the part(s) or product(s).

NOTE: Because some states/jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, the above

limitation or exclusion may not apply.

No Other Warranties:

ProSystems Water Treatment Systems specifically disclaims all other warranties, either express or implied, including, but not limited

to implied warranties of merchantability and fitness for a particular purpose, with regard to the part(s), product(s) and/or any accom-

panying written materials. This limited warranty gives you specific legal rights. You may have other rights that vary from state/juris-

diction to state/jurisdiction.

Order Department Direct Line: 847-758-5973 • Fax: 847-437-5539

Toll-free: 800-811-3489

9