WaterLogic WL380 Operating instructions

Other manuals for WL380

3

Other WaterLogic Water Dispenser manuals

WaterLogic

WaterLogic WL2000IT User manual

WaterLogic

WaterLogic WL350 Operating instructions

WaterLogic

WaterLogic WL800 User manual

WaterLogic

WaterLogic WL100 Manual

WaterLogic

WaterLogic WL250 Manual

WaterLogic

WaterLogic WL100 User manual

WaterLogic

WaterLogic WL200 User manual

WaterLogic

WaterLogic WL900 User manual

WaterLogic

WaterLogic WL Cube Firewall User manual

WaterLogic

WaterLogic WL350 Reference guide

WaterLogic

WaterLogic WL100 User manual

WaterLogic

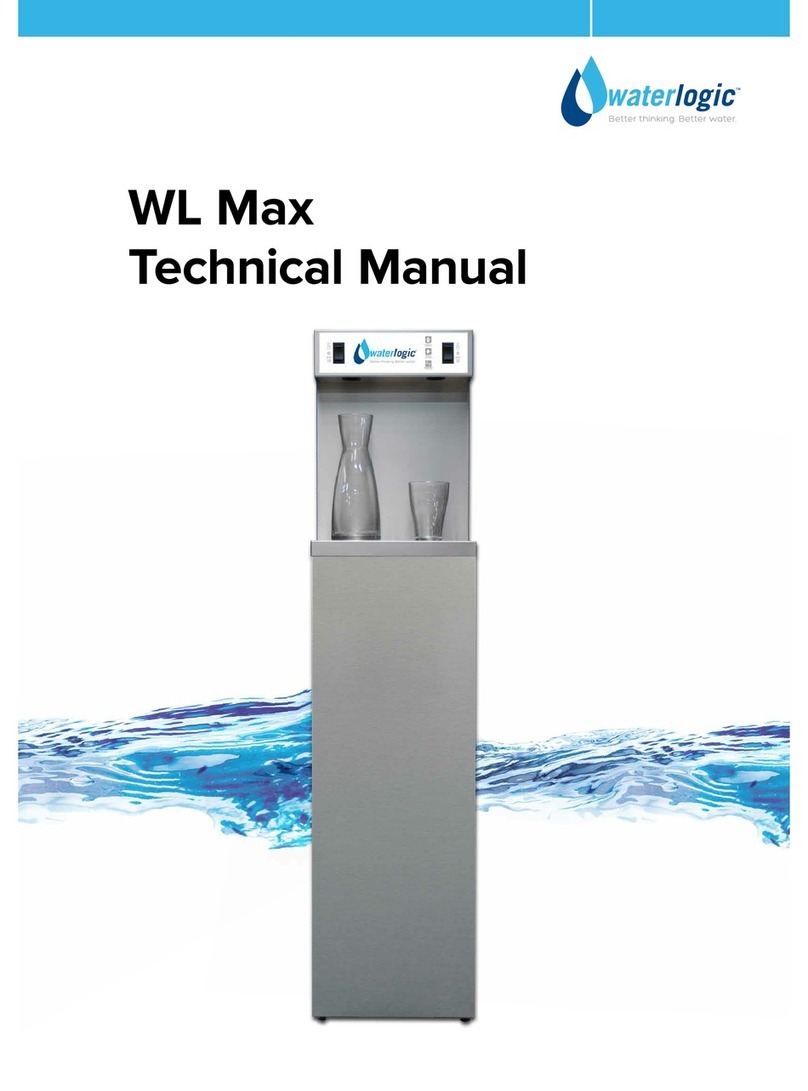

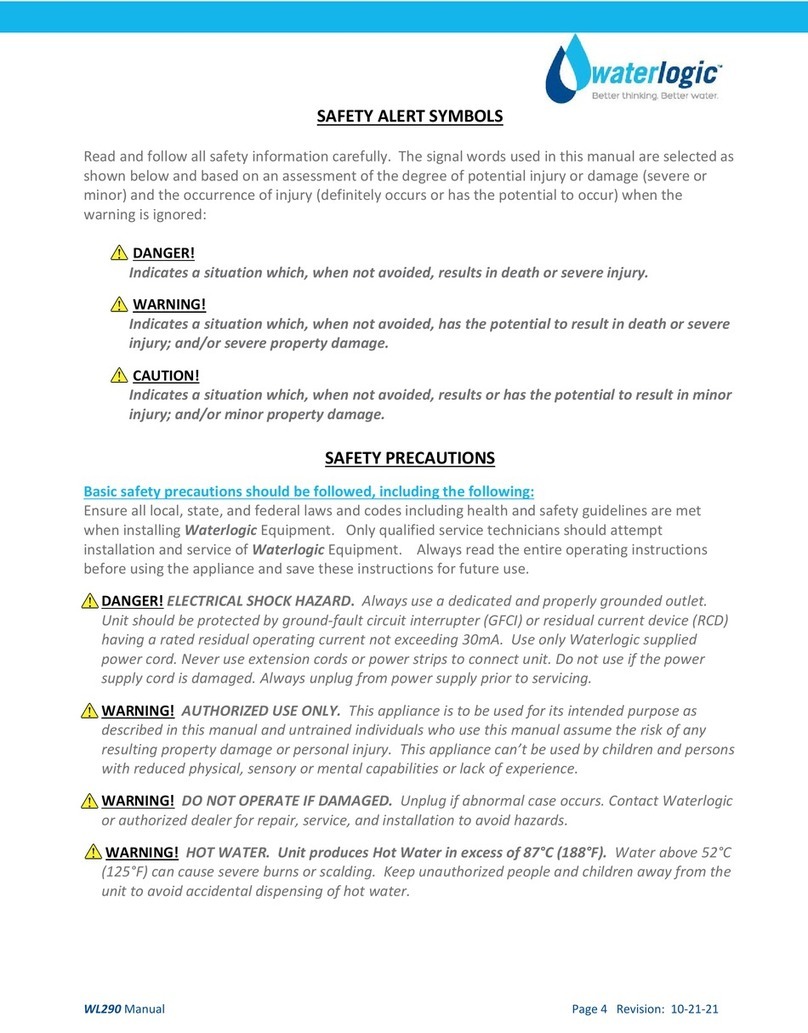

WaterLogic WL Max User manual

WaterLogic

WaterLogic WL250 Operating instructions

WaterLogic

WaterLogic WL400 Series Reference guide

WaterLogic

WaterLogic NIAGARA IB User manual

WaterLogic

WaterLogic WL290 User manual

WaterLogic

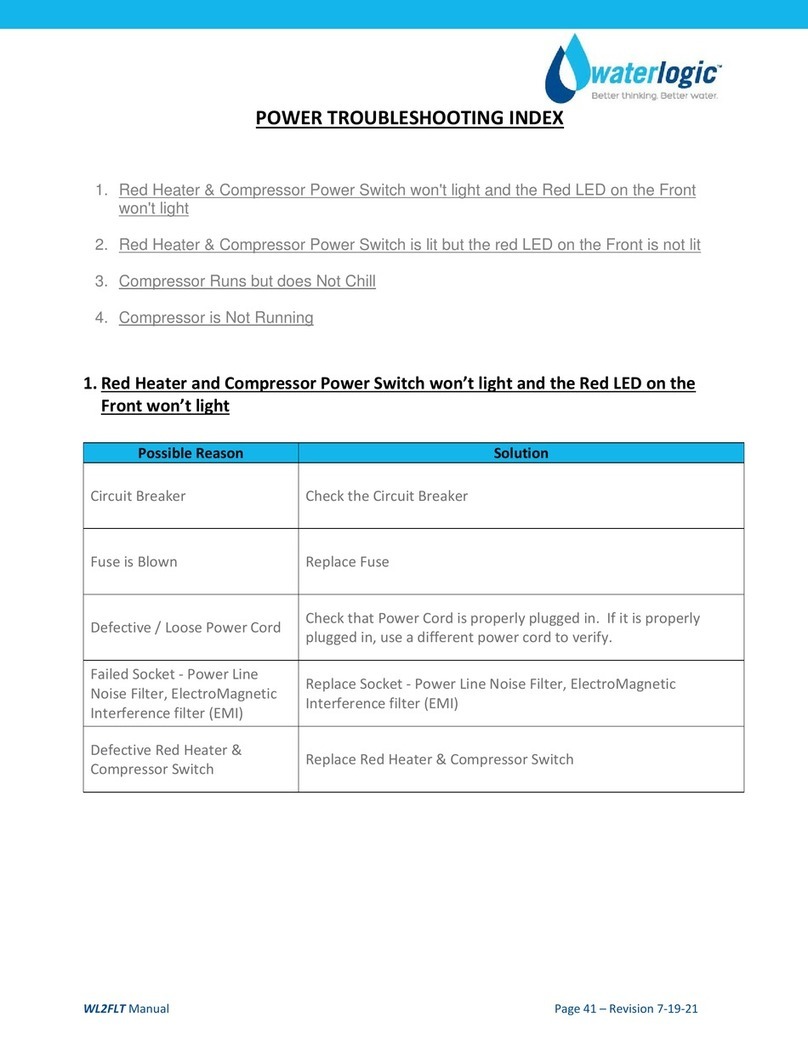

WaterLogic WL2FLT Operating instructions

WaterLogic

WaterLogic WL290 Operating instructions

WaterLogic

WaterLogic WL250 Operating instructions

WaterLogic

WaterLogic WL900 User manual

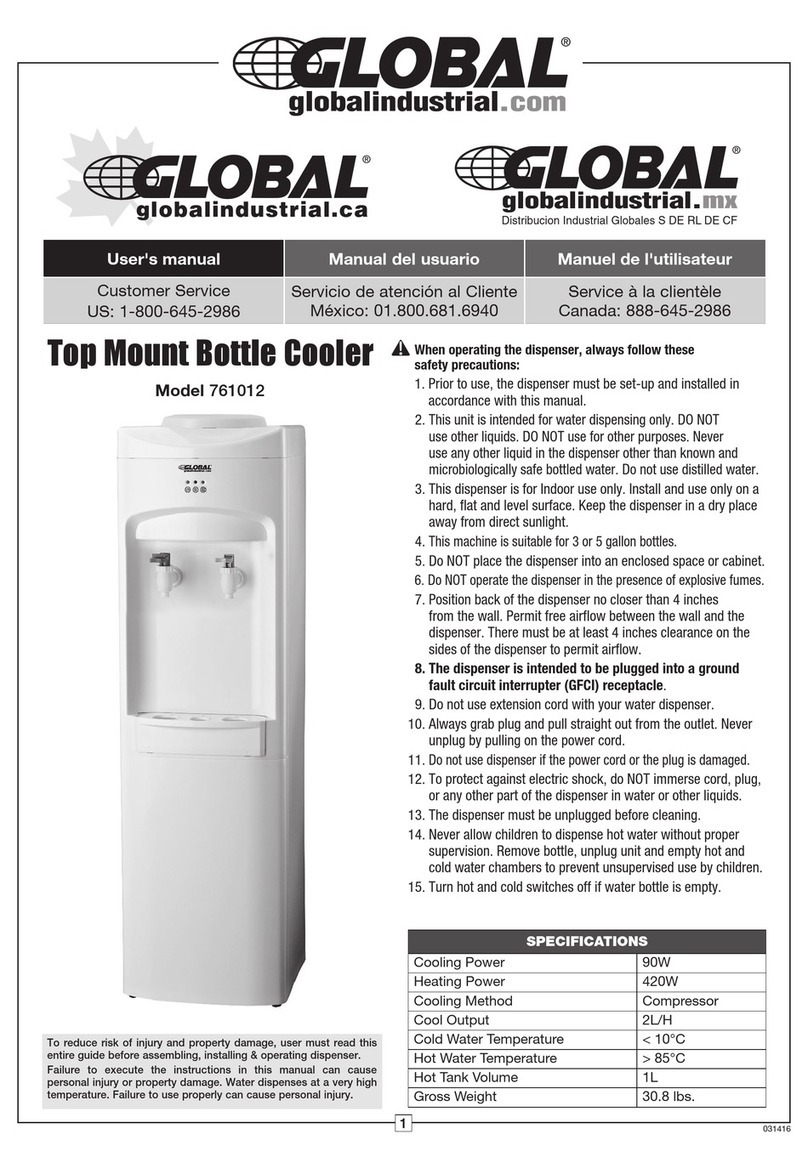

Popular Water Dispenser manuals by other brands

Primo Water

Primo Water 900139 user manual

Grundfos

Grundfos AQtap Installation and operating instructions

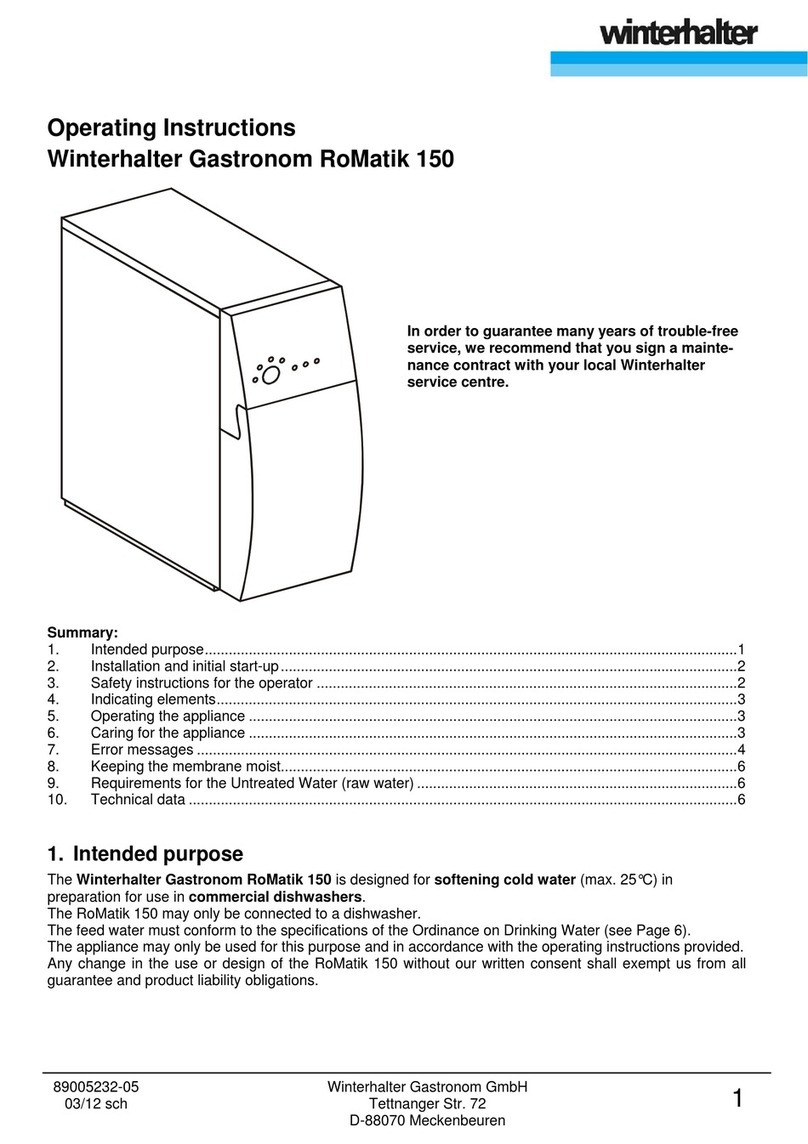

Winterhalter Gastronom

Winterhalter Gastronom RoMatik 150 operating instructions

KineticoPRO

KineticoPRO Compact Commercial Series owner's manual

Kenmore

Kenmore 625.383760 owner's manual

Halsey Taylor

Halsey Taylor SCWT14WQ1K Series owner's manual