3

CONTENTS

Legend symbols ............................................................................................................................ 2

1 Product description ...................................................................................................................... 4

1.1 Intended use ......................................................................................................................... 4

2 precautions ..................................................................................................................................... 4

3 Identication................................................................................................................................... 4

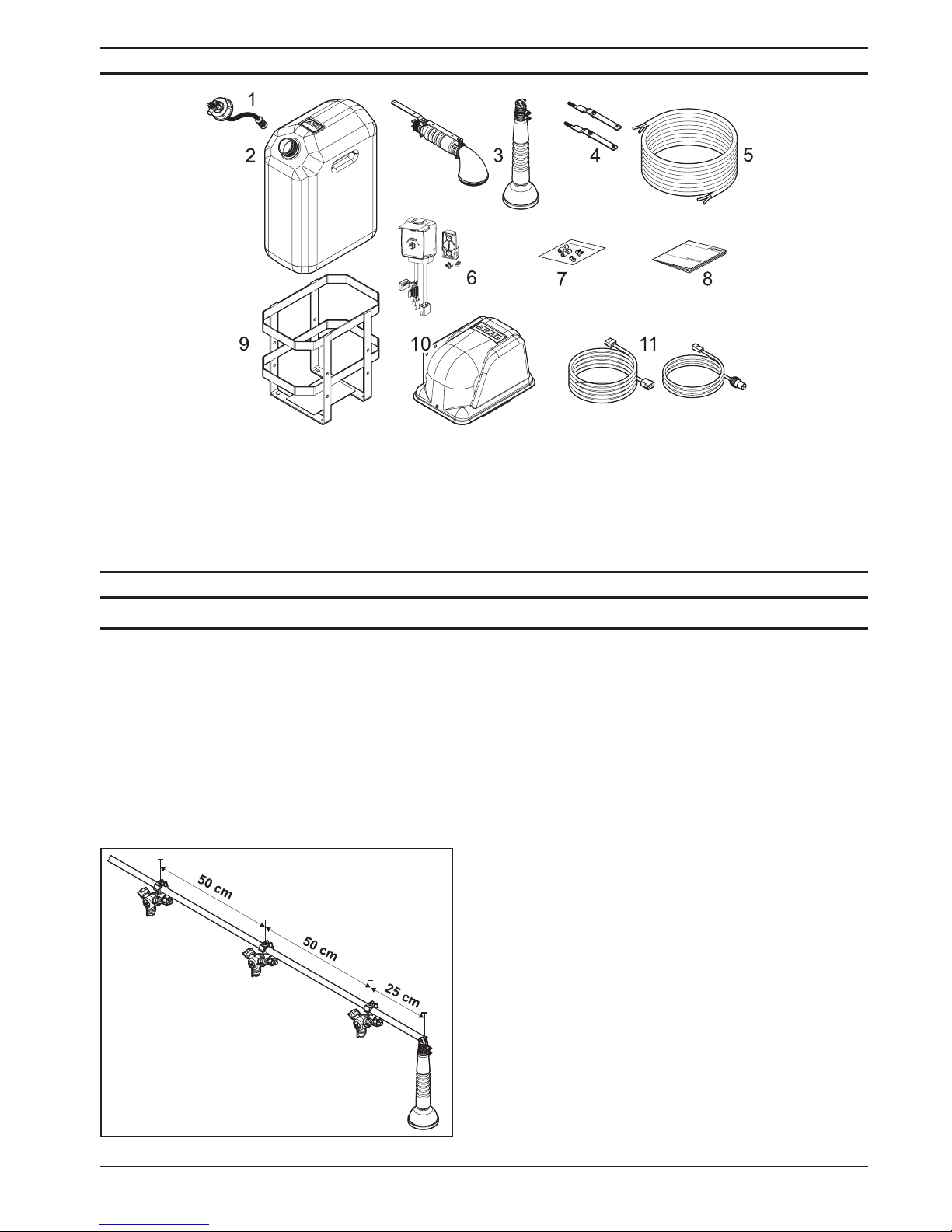

4 Contents of the packaging.......................................................................................................... 5

5 Installation....................................................................................................................................... 5

5.1 Precautions............................................................................................................................ 5

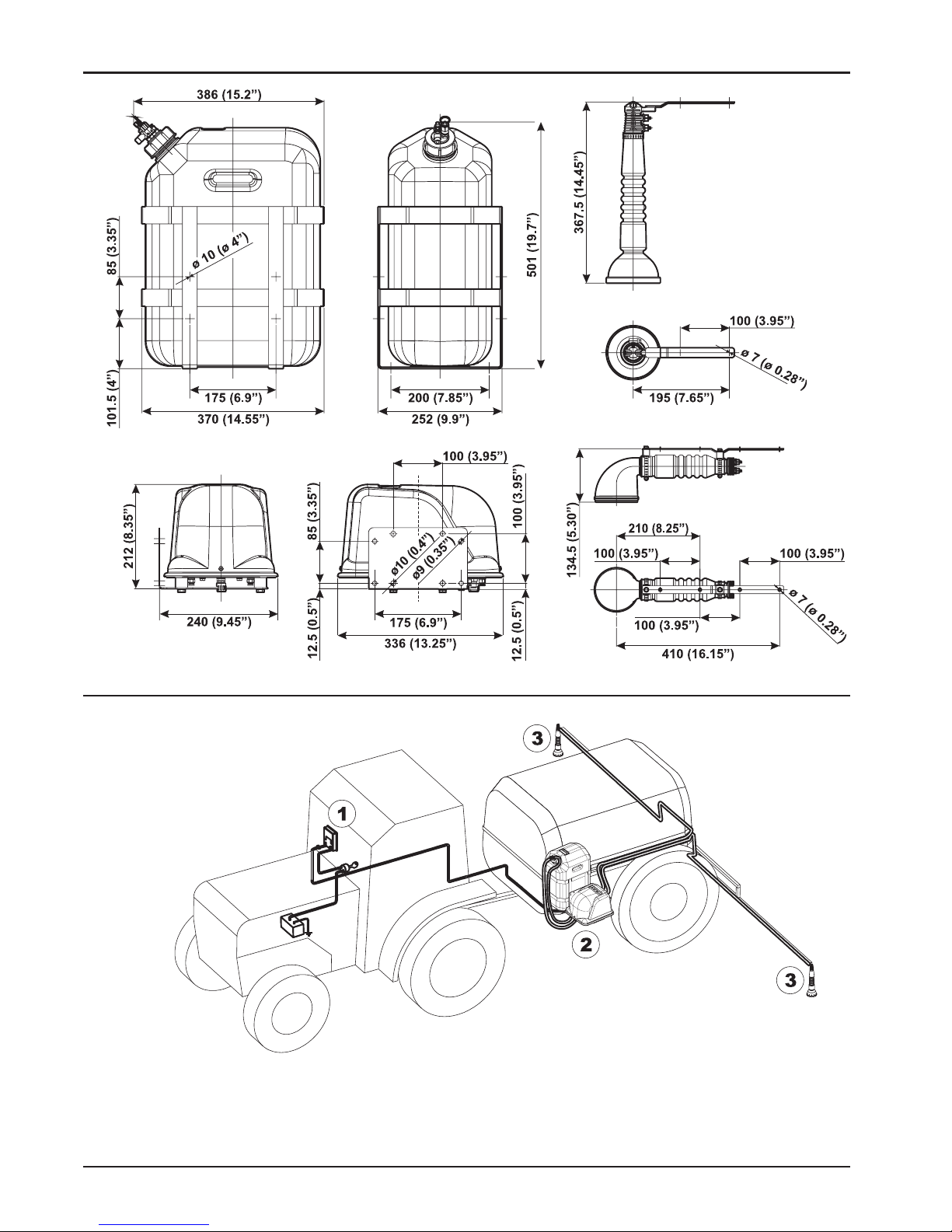

5.2 Overall dimensions - mm (inches)..................................................................................... 6

5.3 Assembly diagram................................................................................................................ 6

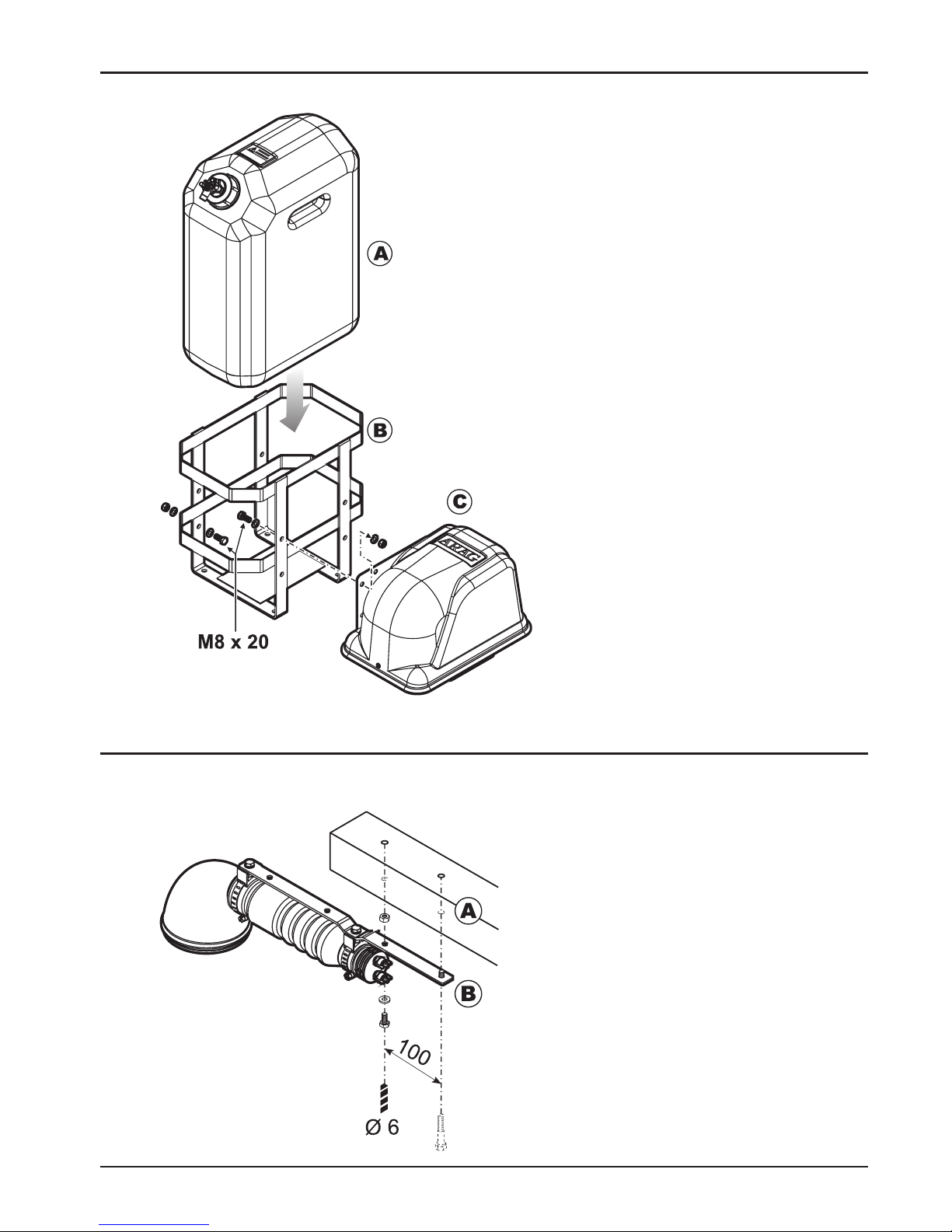

5.4 Installing tank and compressor unit .................................................................................. 7

5.5 Installing the foam markers ................................................................................................ 7

5.6 Mounting the pneumo-hydraulic circuit............................................................................. 8

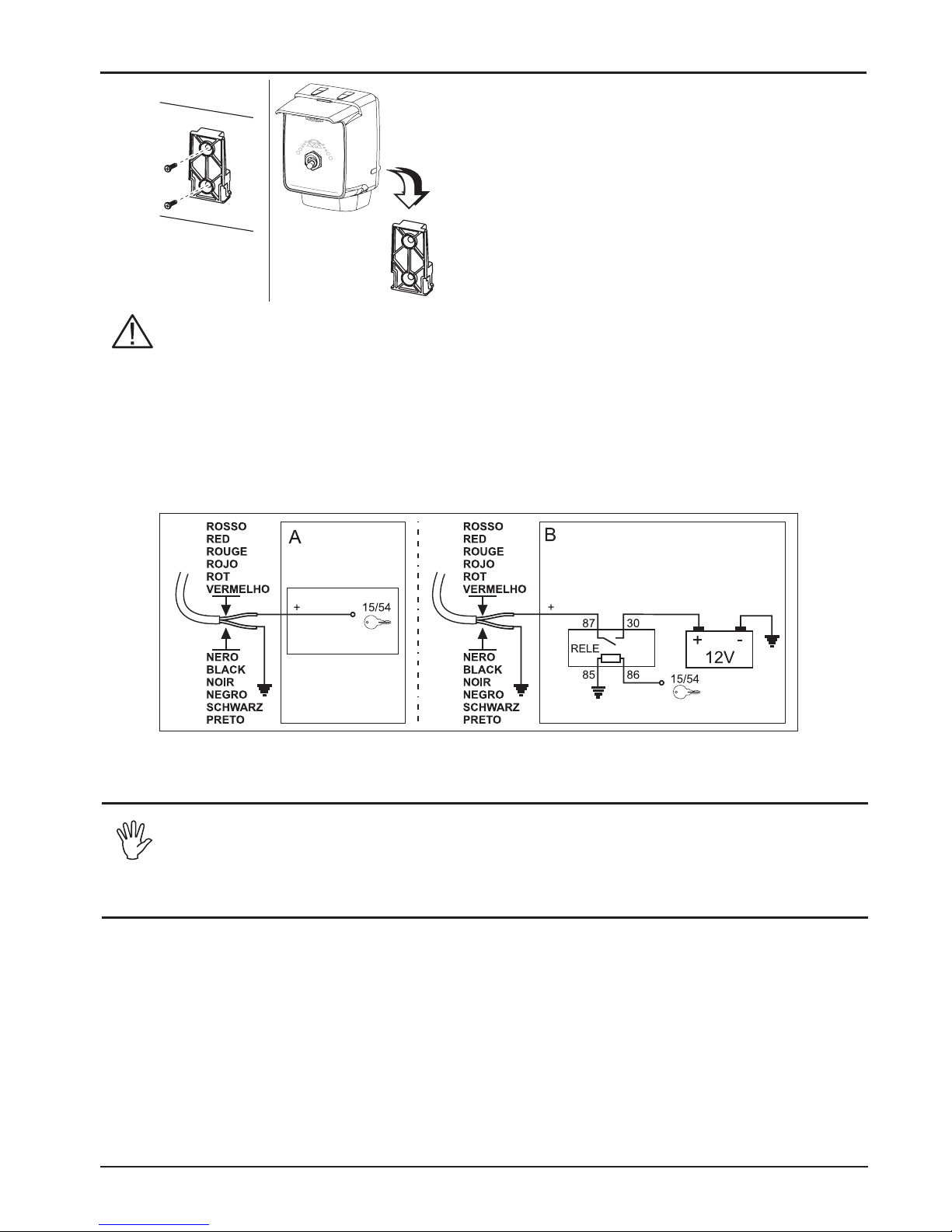

5.7 Installing the control box ..................................................................................................... 9

5.8 Accessory connections: positioning the foam marker control kit ................................. 9

5.9 Final testing ........................................................................................................................... 9

6 Use................................................................................................................................................... 10

6.1 Discharging remaining pressure...................................................................................... 10

6.2 Control devices ................................................................................................................... 10

6.3 Preliminary checks............................................................................................................. 10

6.4 Preparing foaming solution............................................................................................... 10

6.5 Starting and operating........................................................................................................11

6.6 Topping up liquid .................................................................................................................11

6.6.1 Foaming agents...................................................................................................................11

7 Maintenance / diagnostics / repairs ....................................................................................... 12

7.1 Max. pressure valve ........................................................................................................... 12

7.2 Machine down for up to 7 days ........................................................................................ 12

7.3 Machine down for up to 30 days...................................................................................... 13

7.4 Machine down for longer than 30 days .......................................................................... 13

7.5 Reactive maintenance....................................................................................................... 14

7.6 Pipe repairs ......................................................................................................................... 14

7.7 Fuse replacement............................................................................................................... 14

7.8 Troubleshooting .................................................................................................................. 15

7.9 Problems due to the solenoid valves locking up ........................................................... 16

8 Technical data .............................................................................................................................. 16

9 End of life disposal ..................................................................................................................... 16

10 Spare parts.................................................................................................................................... 17

11 Guarantee terms .......................................................................................................................... 22