CONTENTS

• Legend of symbols...................................................................2

• Manual foreword and use.........................................................4

• Manual use modes ...................................................................4

• Limitations ................................................................................4

• Responsibility ...........................................................................4

1 Product description..................................................................5

2 Bravo DSB .................................................................................5

3 Risks and protections before assembly.................................5

4 Intended use .............................................................................5

5 Precautions ...............................................................................5

6 Package content .......................................................................6

7 Position on farming machine ..................................................7

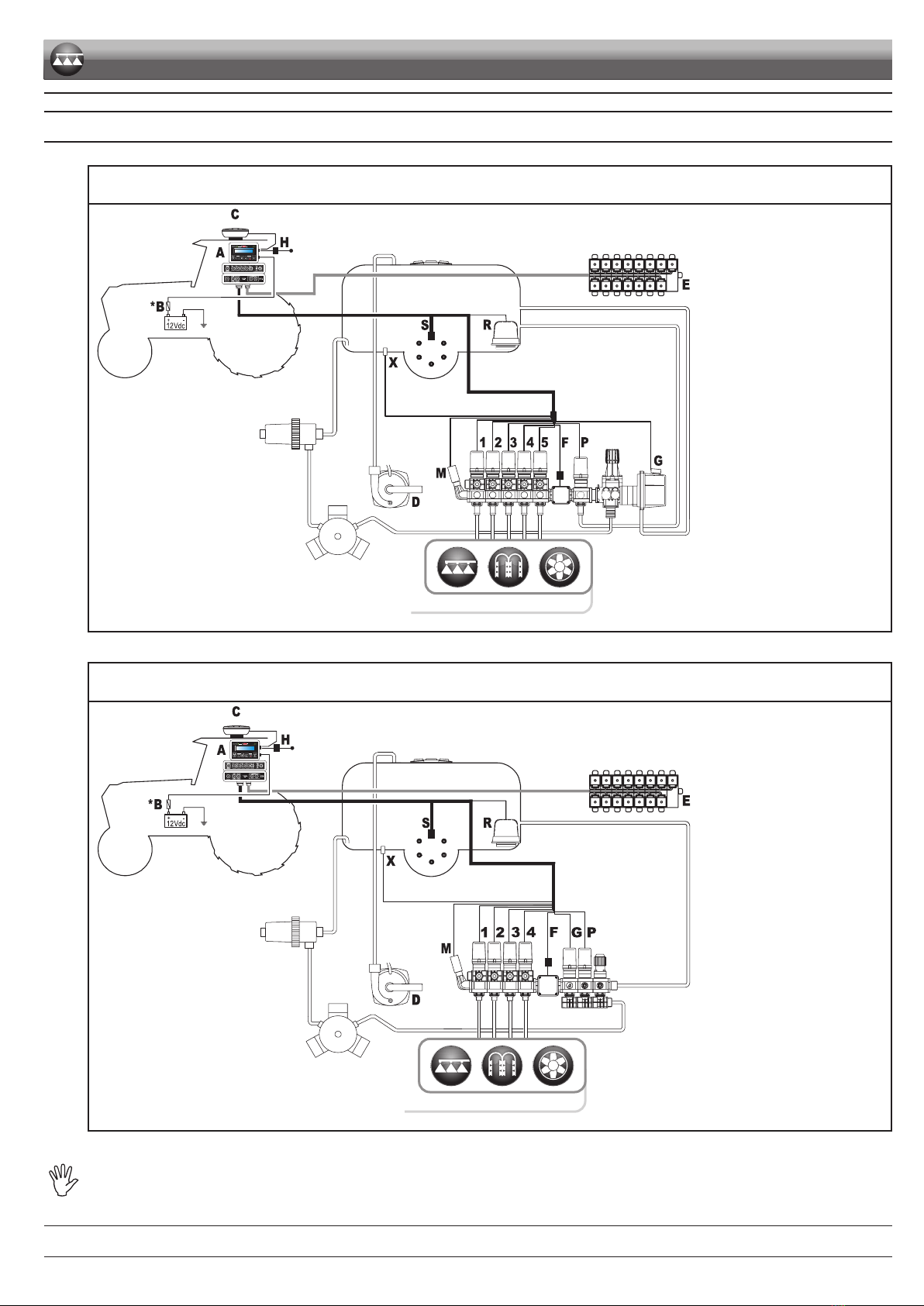

7.1 System recommended composition.................................7

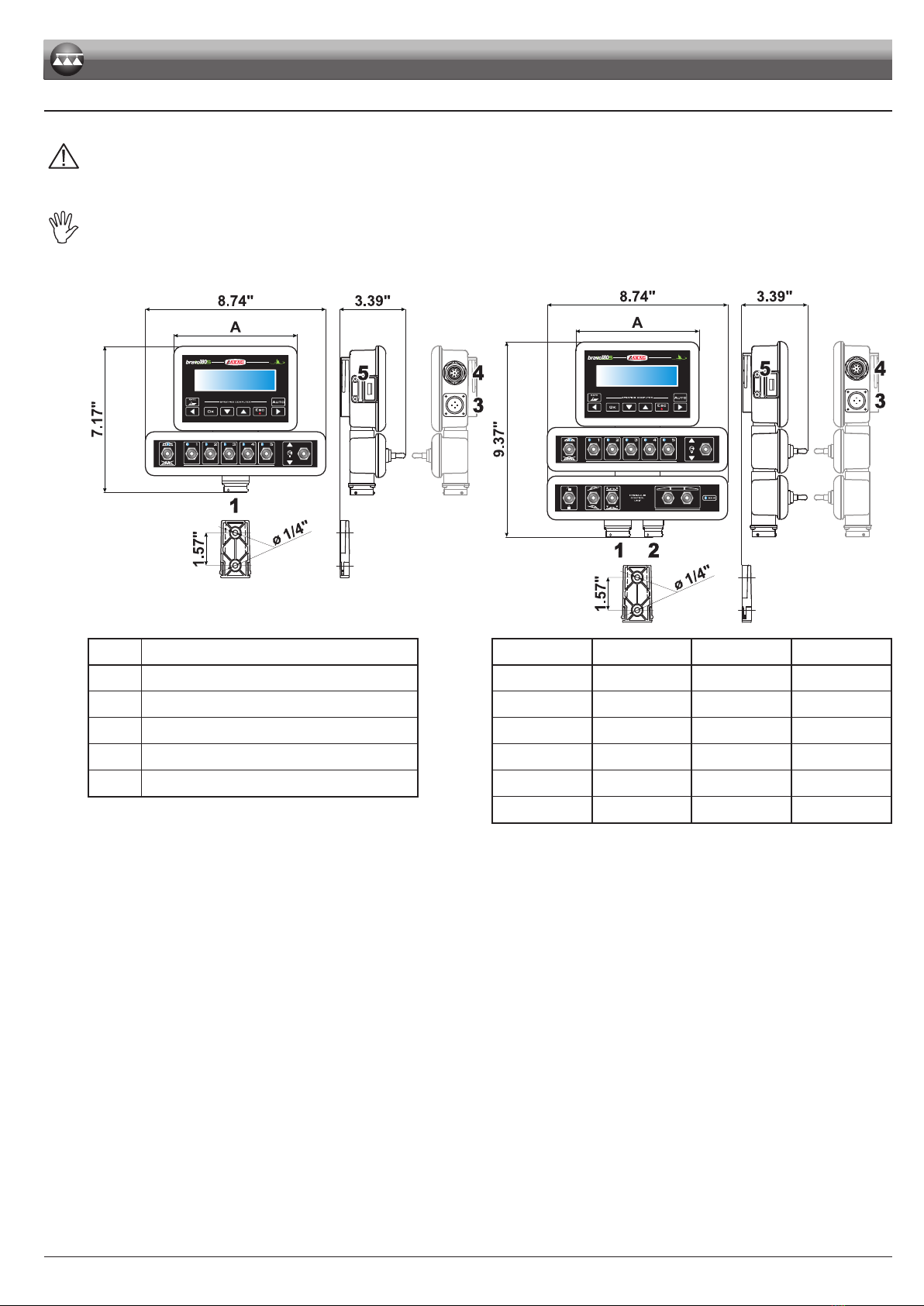

7.2 Computer positioning.......................................................9

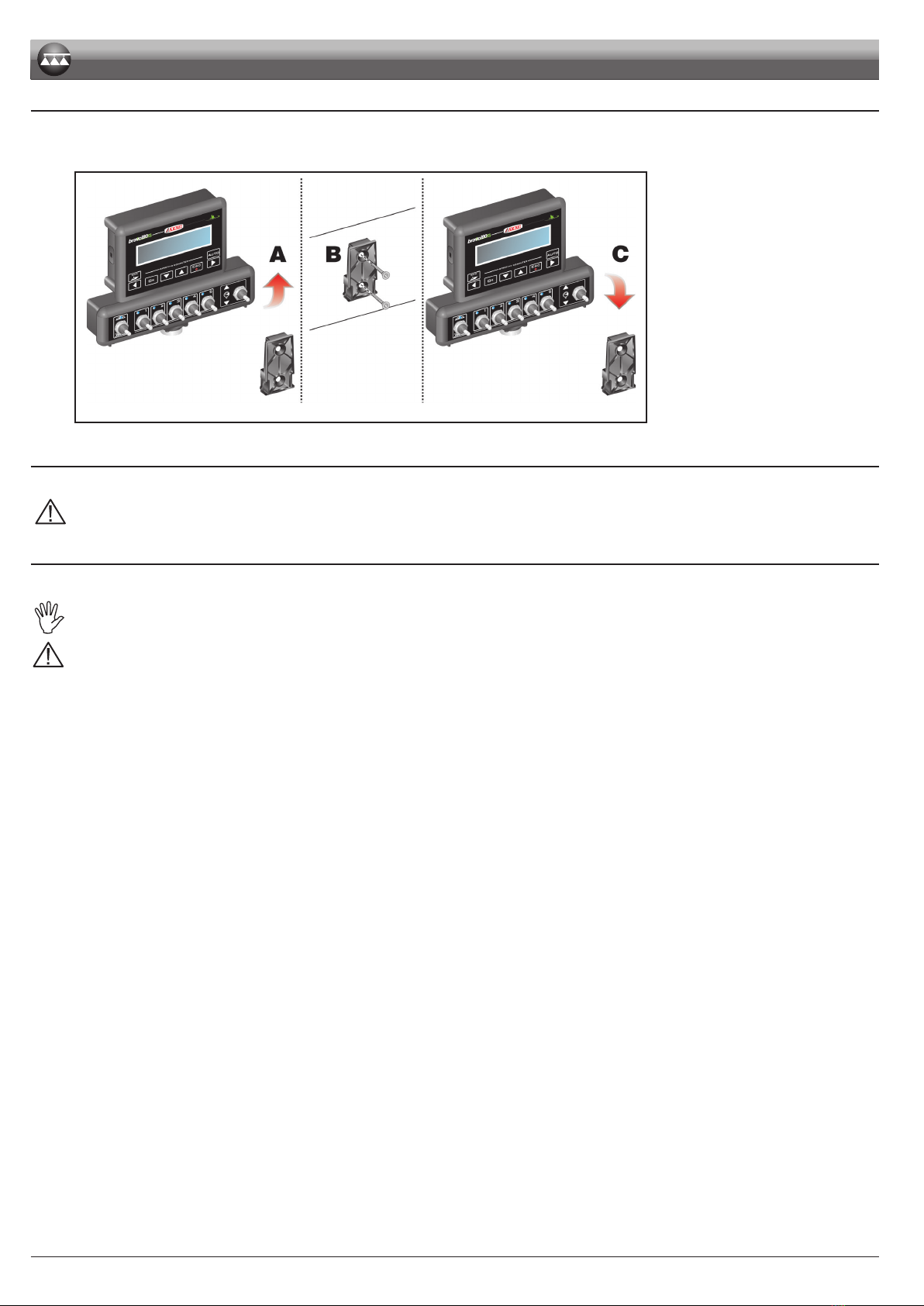

7.3 Bracket fixing .................................................................10

7.4 Control unit position .......................................................10

7.5 Hydraulic unit positioning...............................................10

8 Computer connection to the farming machine....................11

8.1 General precautions for a correct harness position ....... 11

8.2 Power supply connection ...............................................12

9 Harness connection to the control unit, the hydraulic unit

and the available functions....................................................13

9.1 Multicore cable connection ............................................13

9.2 Control unit valve connection.........................................13

9.3 Hydraulic valve connection ............................................14

9.4 Connection of sensors and other available functions....15

9.5 Pendrive.........................................................................15

10 Setup........................................................................................16

10.1 Computer switching on/off..............................................16

10.2 Use of keys for setup .....................................................17

11 Advanced setup ......................................................................18

11.1 Tests and checks before programming ..........................18

11.2 Language.......................................................................19

11.3 Units of measur..............................................................19

11.4 No. of sections ...............................................................19

11.5 Total boom width............................................................19

11.6 Device connect. .............................................................20

11.7 USB log enable..............................................................20

11.8 Speed sensor.................................................................20

11.9 Valves ............................................................................21

11.10 Flowmeter ......................................................................21

11.11 Flowmeter constant........................................................22

11.12 Pressure sensor.............................................................22

11.13 Flow calculation *...........................................................22

11.14 Press. calc. *...................................................................22

11.15 Nozzle qty * ...................................................................22

11.16 Tank source ...................................................................23

11.17 Tank setup .....................................................................23

11.18 Spraying Menu...............................................................24

12 User setting.............................................................................25

12.1 Jobs setup .....................................................................26

12.2 Nozzle data * .................................................................27

12.3 Minimum regulation pressure * ......................................28

12.4 Wheel selection **..........................................................28

12.5 Minimum speed .............................................................28

12.6 Rate correction...............................................................28

12.7 Level correction * ...........................................................29

12.8 Display contrast .............................................................29

12.9 Acoustic signals .............................................................29

12.10 Test device.....................................................................29

12.11 Totalizers........................................................................30

12.12 Settings manag. .............................................................30

13 Use...........................................................................................31

13.1 Display ...........................................................................31

13.2 Controls on computer.....................................................31

13.2.1 Keys to check the computer and the spraying phases ...... 31

13.2.2 Operating switches for control unit valves.......................... 31

13.2.3 Operating switches for hydraulic valves............................. 31

14 Treatment preliminary settings .............................................32

14.1 Selecting the job program (for automatic control only)...32

14.2 Azzeramento dei totalizzatori.........................................32

14.3 Application rate regulation .............................................33

14.3.1 Automatic operation (DEFAULT) ......................................... 33

14.3.2 Manual operation................................................................ 33

14.4 Automatic closure of the main valve ..............................33

14.5 Output menu ..................................................................34

14.5.1 Tank filling ........................................................................... 35

15 Maintenance / diagnostics / repairs ......................................36

15.1 Operation errors.............................................................36

15.2 Troubleshooting..............................................................37

15.3 Cleaning rules................................................................37

16 Technical data.........................................................................38

16.1 Computer technical data ...............................................39

17 End-of-life disposal ................................................................40

18 Guarantee terms .....................................................................40