As of: 06/25/202010000 SERIES INSTALLATION INSTRUCTIONS.pdf

Function:

Description:

®

INSTALLATION INSTRUCTIONS

Page-02

Z:\01 UPDATED FILES\01 CAD\02 ENTRANCES\03 BIFOLD\10000 SERIES\INSTALL INSTUCTIONS\10000 SERIES INSTALLATION INSTRUCTIONS.DWG

JWeller

10000 Series

Offset Top Hung Bi-Fold

Bi-Folding Entrance

WE THANK YOU FOR THE PURCHASING OF YOUR ARCADIA, INC. BI-FOLDING DOOR PRODUCT.

RECEIVING & INSPECTION OF PRODUCT UPON DELIVERY

CRATING WAS DELIVERED DAMAGE FREE (eg. CRATE STILL IN TACK, NO HOLES THROUGH WOOD SIDES, DROPPED).

PRODUCT TO BE CHECKED WITH PACKING LIST TO ENSURE THERE IS NO MISSING ITEMS UPON OPENING CRATES.

ANY & ALL DAMAGES AND/OR MISSING ITEMS NEED TO BE REPORTED TO ARCADIA, INC. IMMEDIATELY.

PRODUCT NEEDS TO BE STORED IN DRY & SAFE AREA UNTIL INSTALLATION TIME TO AVOID DAMAGING OF MATERIAL.

PRE-INSTALL NOTES

CHECK OPENING FOR SIZE, SQUARE & LEVEL.

VERIFY HEADER IS STRUCTURALLY SOUND FOR BI-FOLDING DOOR SYSTEM.

OPENING AND WORK SITE IS DEBRIS FREE FOR SAFETY & NO DAMAGE TO BI-FOLD DOOR SYSTEM.

MAKE SURE ALL SURROUNDING WORK BY OTHER TRADES IS PROTECTED SO INSTALL DOES NOT CAUSE DAMAGE.

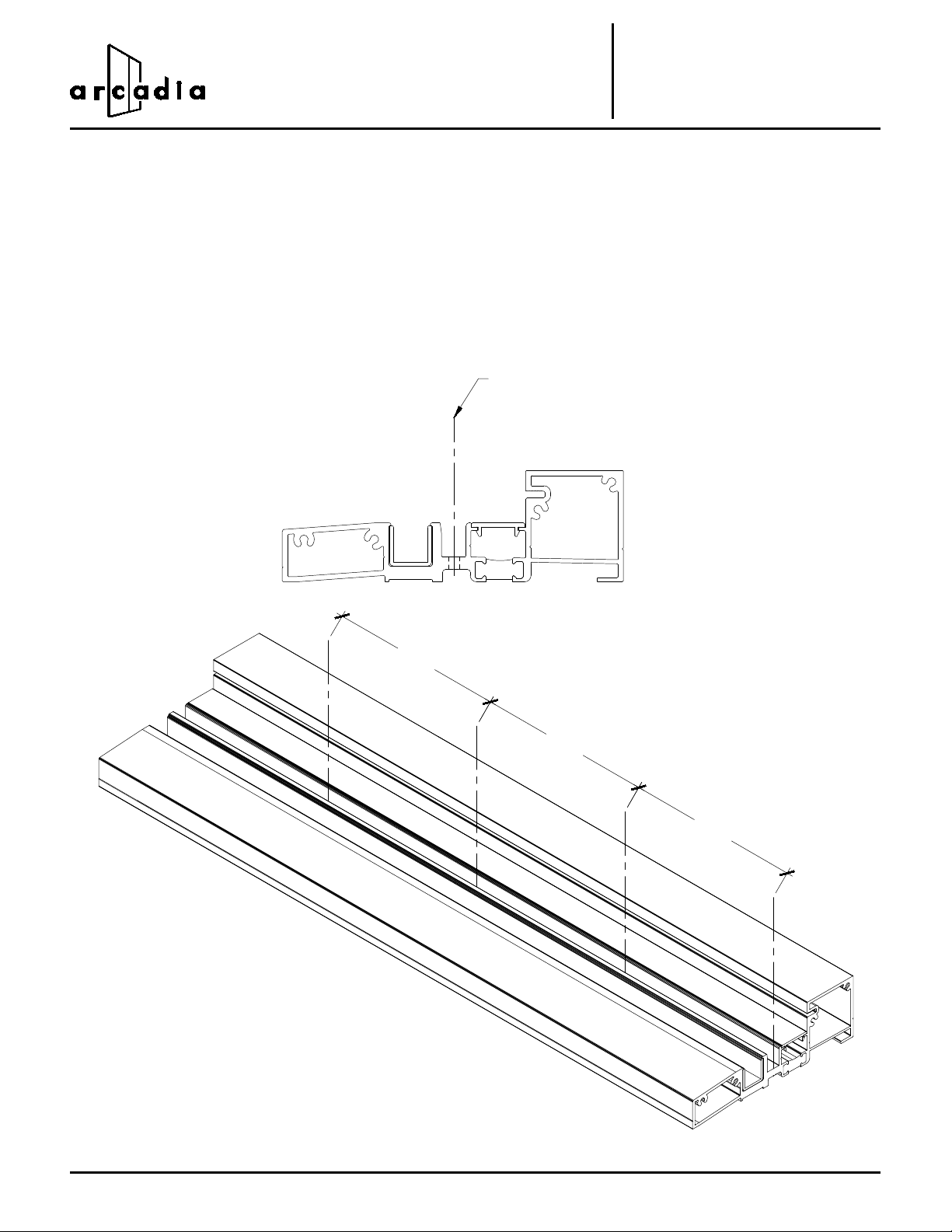

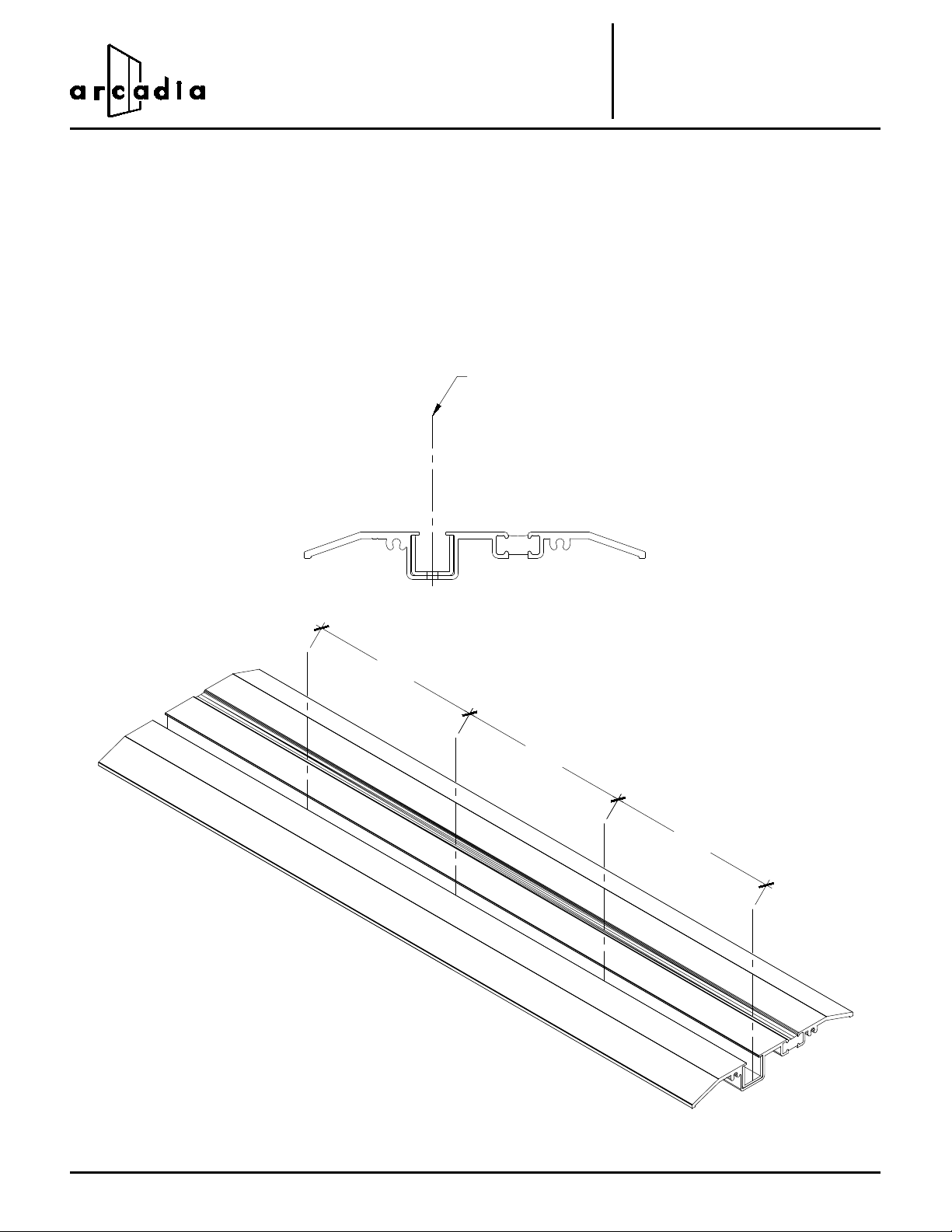

INSTALL NOTES

FRAME IS INSTALLED AT CORRECT LOCATION IN OPENING FRONT TO BACK.

FRAME IS INSTALLED PLUMB, LEVEL & SQUARE.

PROPER SHIMMING USED AT JAMBS TO PREVENT ROCKING.

PROPER SHIMMING AS NEEDED AT SILL.

HEAD TO NOT BE SHIMMED EXCEPT AT ENDS 3" IN FROM END TO PREVENT ROLLING.

HEAD TRACK TO RECEIVE A 1/8" CROWN IN CENTER ONCE INSTALL COMPLETE.

SEALANT APPLIED IN HOLES OF FRAMING PRIOR TO FASTENER INSTALL.

ALL FASTENER HEADS TO HAVE SEALANT APPLIED OVER TOP ONCE INSTALLED.

ALL ADJUSTMENTS MADE TO DOOR HARDWARE & OPERATES CORRECTLY.

FINAL CHECK NOTES

FRAME CHECKED FOR PLUMB, LEVEL & SQUARE.

ALL HARDWARE ADJUSTED & CHECKED FOR ALL FASTENERS TIGHTENED CORRECTLY.

SILL TRACK IS CLEAR OF ALL TRASH & DEBRIS.

WEEP HOLES NEED TO BE CHECKED FOR NO OBSTRUCTIONS.

PROTECT PRODUCT FROM ANY POSSIBLE DAMAGES.

BI-FOLDING DOOR TO BE CLOSED, LOCKED AND NOT USED AFTER INSTALL BY OTHER TRADES.

BI-FOLDING DOOR NOT TO BE USED AS A THOROUGHFARE WHICH CAN CAUSE POSSIBLE DAMAGE.

KEYS & ALL SUPPORTING DOCUMENTS TO BE HANDED OVER TO CONTRACTOR OR HOMEOWNER.