3

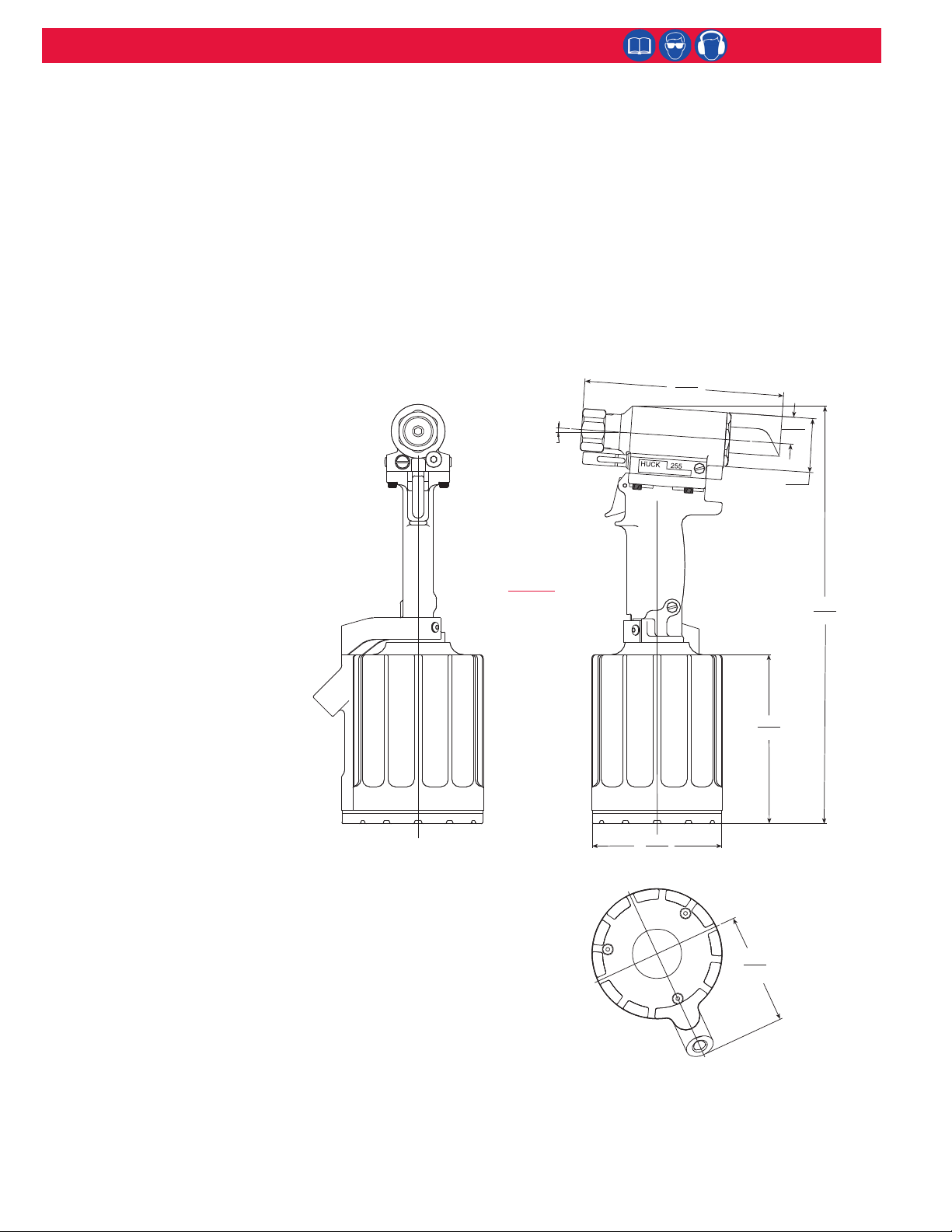

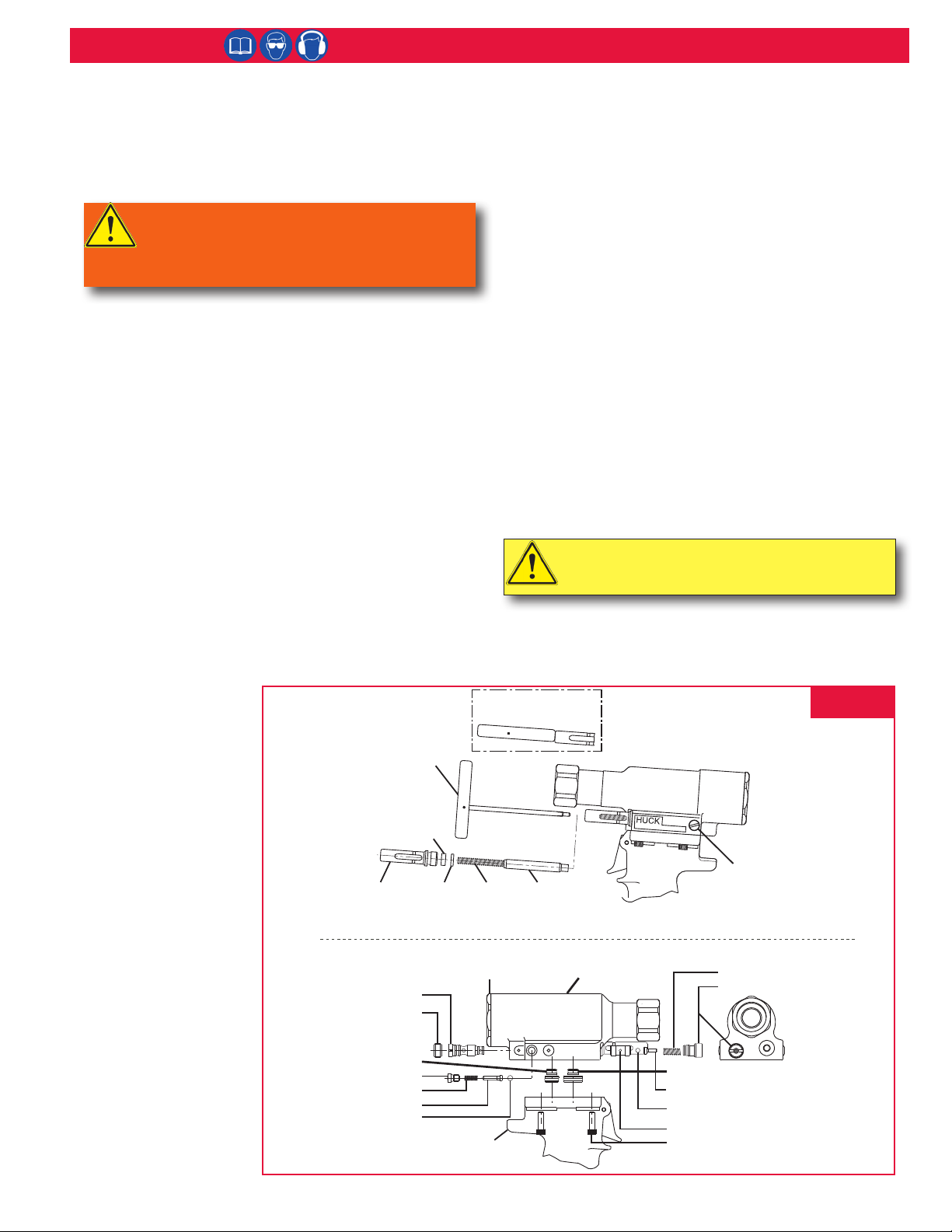

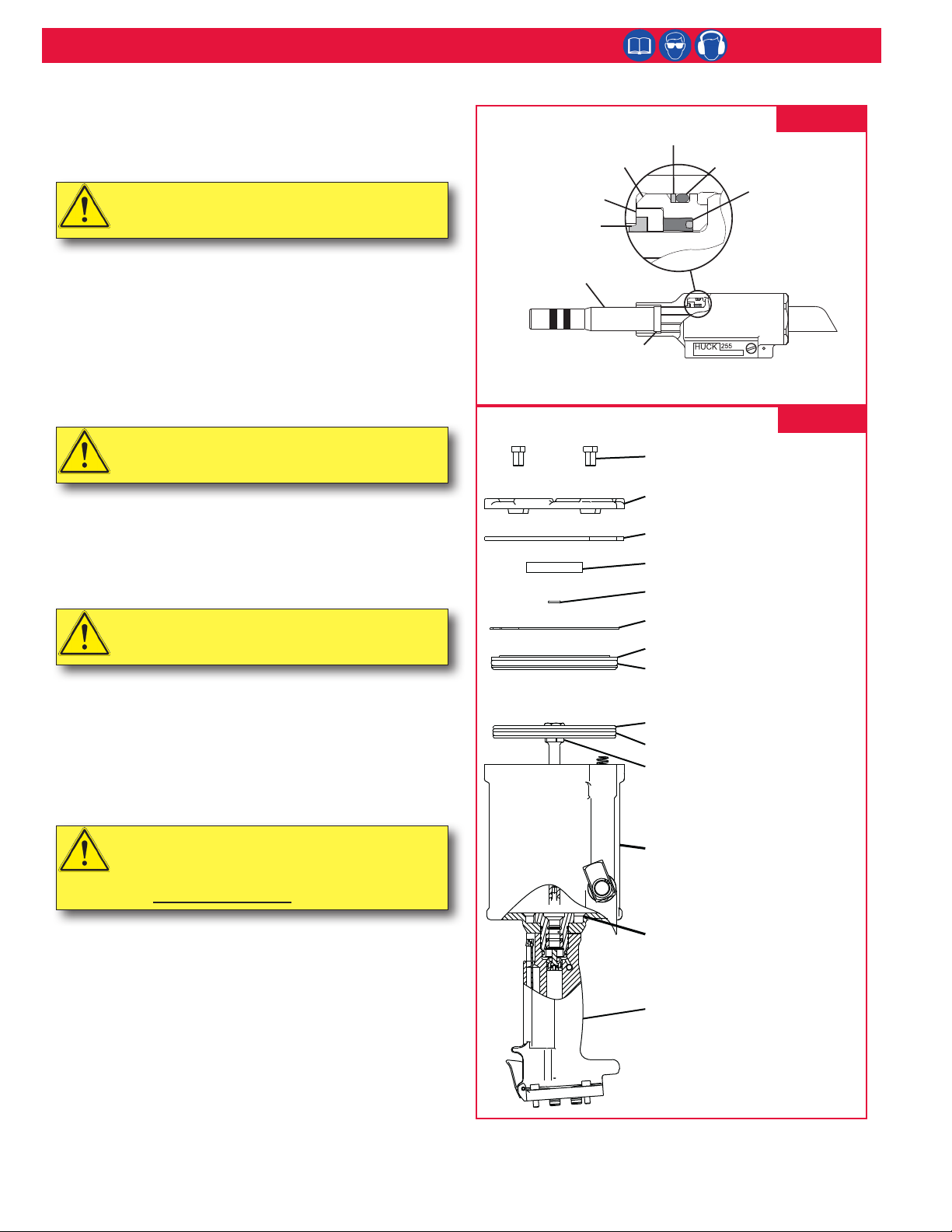

255 Blankdraulic Installation Tool (HK1014)

I. GENERAL SAFETY RULES:

1.Ahalfhourlonghands-ontrainingsessionwithqualiedpersonnelis

recommendedbeforeusingHuckequipment.

2.Huckequipmentmustbemaintainedinasafeworkingconditionatall

times.Toolsandhosesshouldbeinspectedatthebeginningofeach

shift/dayfordamageorwear.Anyrepairshouldbedonebyaqualied

repairmantrainedonHuckprocedures.

3.Formultiplehazards,readandunderstandthesafetyinstructionsbefore

installing,operating,repairing,maintaining,changingaccessorieson,

orworkingneartheassemblypowertool.Failuretodosocanresultin

serious bodily injury.

4.Onlyqualiedandtrainedoperatorsshouldinstall,adjustorusethe

assemblypowertool.

5.Donotmodifythisassemblypowertool.Thiscanreduceeectivenessof

safetymeasuresandincreaseoperatorrisk.

6.Donotdiscardsafetyinstructions;givethemtotheoperator.

7.Donotuseassemblypowertoolifithasbeendamaged.

8.Toolsshallbeinspectedperiodicallytoverifyallratingsandmarkings

required, and listed in the manual, are legibly marked on the tool. The

employer/operatorshallcontactthemanufacturertoobtainreplacement

markinglabelswhennecessary.Refertoassemblydrawingandpartslist

forreplacement.

9. Tool is only to be used as stated in this manual. Any other use is

prohibited.

10.ReadMSDSSpecicationsbeforeservicingthetool.MSDS

specicationsareavailablefromtheproductmanufactureroryourHuck

representative.

11.OnlygenuineHuckpartsshallbeusedforreplacementsorspares.Use

ofanyotherpartscanresultintoolingdamageorpersonalinjury.

12.Neverremoveanysafetyguardsorpintaildeectors.

13.Neverinstallafastenerinfreeair.Personalinjuryfromfastenerejecting

may occur.

14.Whereapplicable,alwaysclearspentpintailoutofnoseassembly

before installing the next fastener.

15.Checkclearancebetweentriggerandworkpiecetoensurethereisno

pinchpointwhentoolisactivated.Remotetriggersareavailablefor

hydraulictoolingifpinchpointisunavoidable.

16.Donotabusetoolbydroppingorusingitasahammer.Neveruse

hydraulicorairlinesasahandleortobendorprythetool.Reasonable

careofinstallationtoolsbyoperatorsisanimportantfactorin

maintainingtooleciency,eliminatingdowntime,andpreventingan

accidentwhichmaycauseseverepersonalinjury.

17.Neverplacehandsbetweennoseassemblyandworkpiece.Keephands

clear from front of tool.

18.Toolswithejectorrodsshouldneverbecycledwithoutnoseassembly

installed.

19.Whentwopiecelockboltsarebeingusedalwaysmakesurethecollar

orientationiscorrect.Seefastenerdatasheetforcorrectpositioning.

II. PROJECTILE HAZARDS:

1.Riskofwhippingcompressedairhoseiftoolispneudraulicorpneumatic.

2.Disconnecttheassemblypowertoolfromenergysourcewhenchanging

inserted tools or accessories.

3.Beawarethatfailureoftheworkpiece,accessories,ortheinsertedtool

itselfcangeneratehighvelocityprojectiles.

4.Alwayswearimpactresistanteyeprotectionduringtooloperation.The

gradeofprotectionrequiredshouldbeassessedforeachuse.

5. The risk of others should also be assessed at this time.

6.Ensurethattheworkpieceissecurelyxed.

7.Checkthatthemeansofprotectionfromejectionoffastenerorpintailis

inplaceandoperative.

8.Thereispossibilityofforcibleejectionofpintailsorspentmandrelsfrom

front of tool.

III. OPERATING HAZARDS:

1.Useoftoolcanexposetheoperator’shandstohazardsincluding:

crushing,impacts,cuts,abrasionsandheat.Wearsuitableglovesto

protecthands.

2.Operatorsandmaintenancepersonnelshallbephysicallyabletohandle

thebulk,weightandpowerofthetool.

3. Hold the tool correctly and be ready to counteract normal or sudden

movementswithbothhandsavailable.

4.Maintainabalancedbodypositionandsecurefooting.

5.Releasetriggerorstopstartdeviceincaseofinterruptionofenergy

supply.

6.Useonlyuidsandlubricantsrecommendedbythemanufacturer.

7.Avoidunsuitablepostures,asitislikelyforthesenottoallow

counteractingofnormalorunexpectedtoolmovement.

8.Iftheassemblypowertoolisxedtoasuspensiondevice,makesure

thatxationissecure.

9.Bewareoftheriskofcrushingorpinchingifnoseequipmentisnottted.

IV. REPETITIVE MOTION HAZARDS:

1.Whenusingassemblypowertool,theoperatorcanexperience

discomfortinthehands,arms,shoulders,neckorotherpartsofthe

body.

2.Whenusingtool,theoperatorshouldadoptacomfortableposture

whilemaintainingasecurefootingandavoidawkwardorobalanced

postures.

3.Theoperatorshouldchangepostureduringextendedtaskstohelpavoid

discomfort and fatigue.

4.Iftheoperatorexperiencessymptomssuchaspersistentorrecurring

discomfort,pain,throbbing,aching,tingling,numbness,burning

sensationsorstiness,thesewarningsshouldnotbeignored.The

operatorshouldtelltheemployerandconsultaqualiedhealth

professional.

V. ACCESSORIES HAZARDS:

1.Disconnecttoolfromenergysupplybeforechanginginsertedtoolor

accessory.

2.Useonlysizesandtypesofaccessoriesandconsumablesthatare

recommended.Donotuseothertypesorsizesofaccessoriesor

consumables.

VI. WORKPLACE HAZARDS:

1.Beawareofslipperysurfacescausedbyuseofthetoolandoftrip

hazardscausedbytheairlineorhydraulichose.

2. Proceed with caution while in unfamiliar surroundings; there could be

hiddenhazardssuchaselectricityorotherutilitylines.

3.Theassemblypowertoolisnotintendedforuseinpotentiallyexplosive

environments.

4.Toolisnotinsulatedagainstcontactwithelectricalpower.

5.Ensuretherearenoelectricalcables,gaspipes,etc.,whichcancausea

hazardifdamagedbyuseofthetool.

VII. NOISE HAZARDS:

1.Exposuretohighnoiselevelscancausepermanent,disablinghearing

lossandotherproblemssuchastinnitus,thereforeriskassessmentand

theimplementationofpropercontrolsisessential.

2.Appropriatecontrolstoreducetheriskmayincludeactionssuchas

dampingmaterialstopreventworkpiecefrom‘ringing’.

3.Usehearingprotectioninaccordancewithemployer’sinstructionsandas

requiredbyoccupationalhealthandsafetyregulations.

4.Operateandmaintaintoolasrecommendedintheinstructionhandbook

topreventanunnecessaryincreaseinthenoiselevel.

5.Select,maintainandreplacetheconsumable/insertedtoolas

recommendedtopreventanunnecessaryincreaseinnoise.

6.Ifthepowertoolhasasilencer,alwaysensurethatitisinplaceandin

goodworkingorderwhenthetoolisbeingoperated.

VIII. VIBRATION HAZARDS:

1.Exposuretovibrationcancausedisablingdamagetothenervesand

bloodsupplytothehandsandarms.

2.Wearwarmclothingwhenworkingincoldconditionsandkeephands

warm and dry.

3.Ifnumbness,tingling,painorwhiteningoftheskininthengersor

hands,stopusingthetool,tellyouremployerandconsultaphysician.

4.Supporttheweightofthetoolinastand,tensionerorbalancerinorder

tohavealightergriponthetool.

IX. PNEUMATIC / PNEUDRAULIC TOOL SAFETY INSTRUCTIONS:

1.Airunderpressurecancausesevereinjury.

2.Alwaysshutoairsupply,drainhoseofairpressureanddisconnecttool

fromairsupplywhennotinuse,beforechangingaccessoriesorwhen

makingrepairs.

3.Neverdirectairatyourselforanyoneelse.

4.Whippinghosescancausesevereinjury,alwayscheckfordamagedor

loosehosesandttings.

5. Cold air should be directed away from hands.

6.Wheneveruniversaltwistcouplings(clawcouplings)areused,lockpins

shallbeinstalledandwhip-checksafetycablesshallbeusedtosafeguard

againstpossiblehosetohoseorhosetotoolconnectionfailure.

7.Donotexceedmaximumairpressurestatedontool.

8.Nevercarryanairtoolbythehose.

Safety Instructions

GLOSSARYOFTERMSANDSYMBOLS:

- Productcomplieswithrequirementssetforthby

therelevantEuropeandirectives.

- Readmanualpriortousingthisequipment.

- Eyeprotectionisrequiredwhileusingthis

equipment.

- Hearingprotectionisrequiredwhileusingthis

equipment.

Notes:areremindersofrequiredprocedures.

Bold, Italic type, and underline:emphasizeaspecic

instruction.

WARNINGS: Must be understood to avoid

severe personal injury.

CAUTIONS: Show conditions that will damage

equipment or structure.