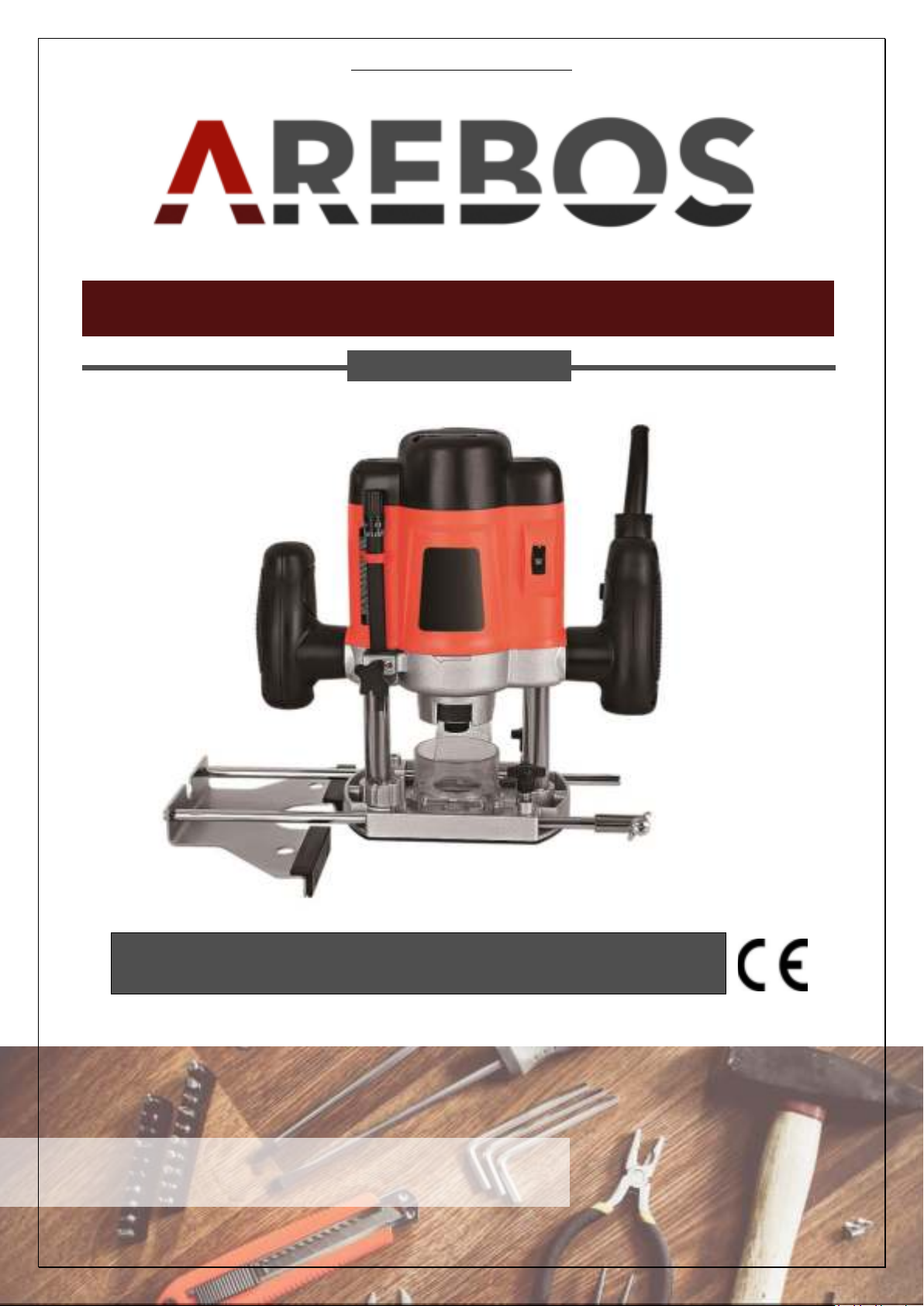

User’s Manual – AREBOS Plunge Router

5

from heat, oil, sharp edges or moving parts. Damaged or tangled cords raise the risk of an

electrical shock.

•When operating a tool outdoors, use only extension cords which are usable for the

exterior. The use of an appropriate extension cord reduces the risk of an electrical cord.

•When operating a power tool in a damp or moist location and it is not avoidable, use a

residual current supply. The use of a residual current supply reduces the risk of an electrical

shock.

•If the supply cord of this power tool is damaged, it must be replaced by a specially

prepared cord available through the service organisation.

1.2.3 Personal safety

•Stay alert, watch what you are doing and use common sense when operating a power tool.

Do not use a power tool while you are tired or under the influence of drugs, alcohol or

medication. A moment of negligence while using the power tool can cause serious injuries.

•Use personal protective equipment and always wear eye protection. Wearing personal

protective equipment, such as dust mask, slip-proof safety shoes, safety helmet or hearing

protection, depending on the type of use of the power tool, reduces the risk of injuries.

•Prevent unintentional starting. Ensure the switch is on the off position before connecting

the tool to the power source, picking up or carrying the tool. When you put your finger on

the switch while carrying the power tool or you connect the tool on the on position to the

power source, that can cause accidents.

•Remove any adjusting key or wrench before turning the power tool on. A tool or wrench

which is adjusted can cause injuries.

•Take care to keep a normal position. Keep proper footing and balance at all times. Thus you

can control the power tool better in unexpected situations.

•Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothing or long hair can be caught by the moving parts.

•If devices are provided for the connection of dust extraction and collection facilities, ensure

these are connected and properly used. The use of a dust extraction can reduce dangers

caused by dust.

1.2.4 Power tool use and care

•Do not force the power tool. Use the correct power tool for your application. You better

work with matching power tool and safer in the indicated power range.

•Do not use a power tool with a damaged switch. A power tool that does not turn on or off,

is dangerous and must be repaired.

•Disconnect the plug from the power source and/or remove the battery before making any

adjustments, changing accessories, or storing power tools. This precaution prevents the

unintentional start of the power tool.

•Store the idle power tools out of reach of children. Do not allow persons unfamiliar with

the power tool or these instructions to operate the power tool. Power tools are dangerous,

if used by inexperienced persons.

•Maintain power tools. Check for misalignment or binding of moving parts, breakage of

parts and any other condition that may affect the power tool’s operation. If damaged, have

the power tool repaired before use. Many accidents are caused by badly maintained power

tools.

•Keep the cutting tool sharp and clean. Well maintained cutting tools with sharp cutting

edges jam less and are easier to use.

•Use the power tool, accessories and tool bits etc. in accordance with these instructions.

Take account of the working conditions and the work to be performed. The use of power

tools for other applications than indicated can cause dangerous situations.