Contents

ⅠSafety Precautions ................................................................................................... 1

ⅡInstallation Location and Matters Needing Attention................................................. 3

1 How to select the installation location for the indoor unit ................................... 3

2 Electric Wiring.................................................................................................... 4

3 Earthing Requirements ...................................................................................... 4

4 Accessories for Installation ................................................................................ 4

ⅢInstallation Instructions ............................................................................................. 5

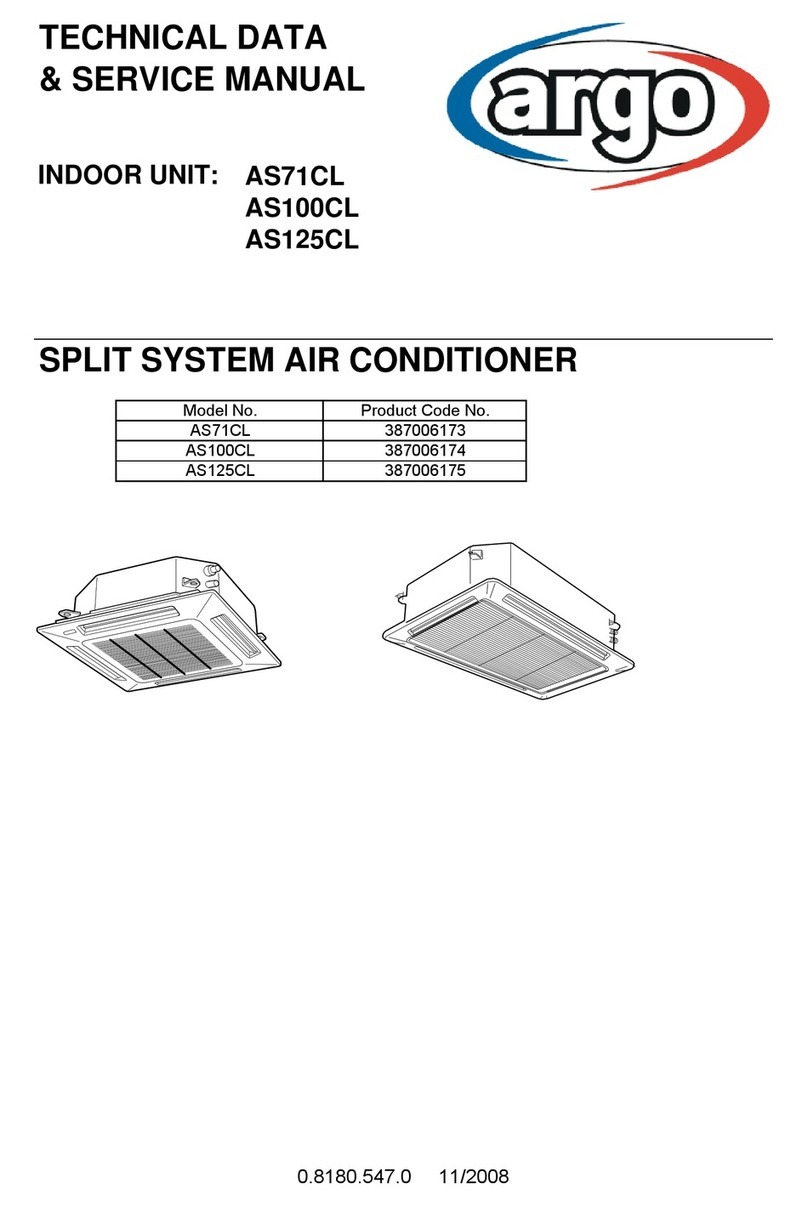

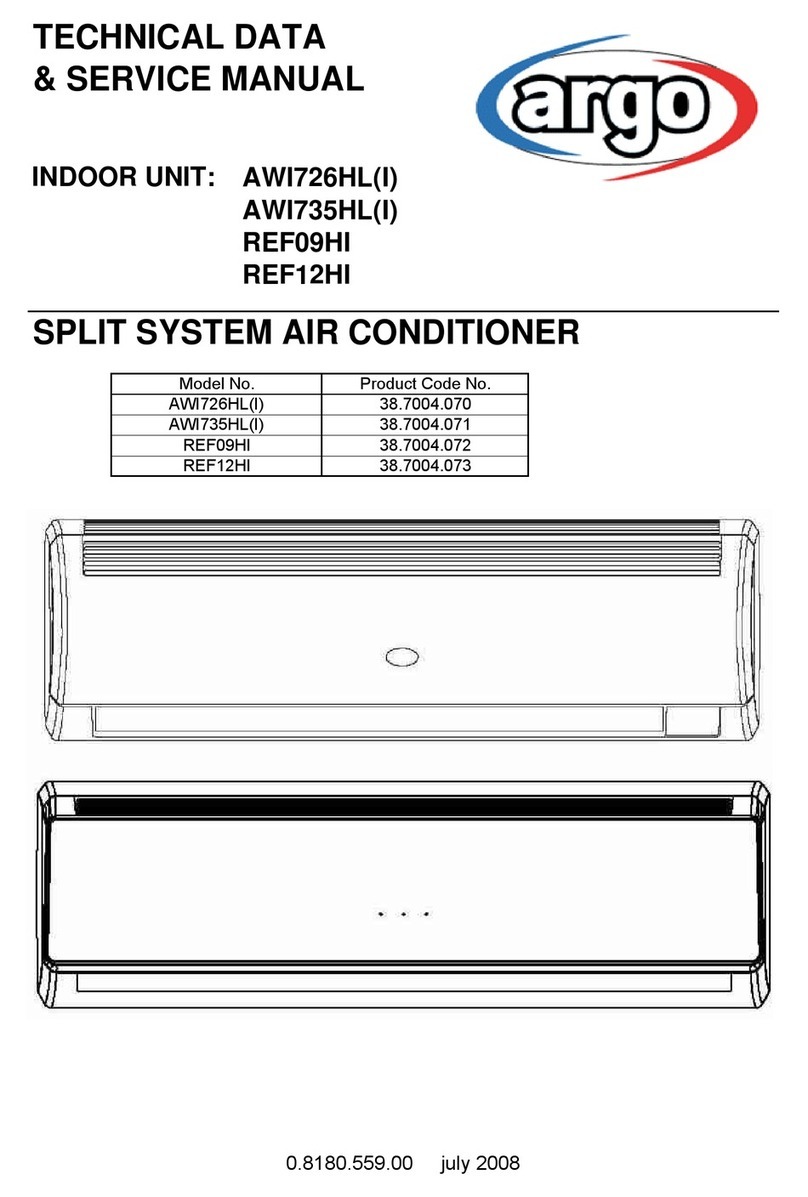

1 Outline Dimension Drawings of the Indoor Unit ................................................. 5

2 Dimension Requirements on the Installation Space of the Indoor Unit .............. 6

3 Installation of the Indoor Unit ............................................................................. 6

4 Horizontality Check of the Indoor Unit ............................................................... 8

5 Installation of the Air Supply Duct ...................................................................... 8

6 Drawings of the Air Supply Outlet and Return Air Inlet..................................... 10

7 Installation of the Return Air Duct .................................................................... 10

8 Installation of the Condensate Pipe ................................................................. 11

9 Design of the Drain Pipe.................................................................................. 12

10 Installation of the Drain Pipe .......................................................................... 12

11 Precautions for the Lift Pipe ........................................................................... 13

12 Test for the Drainage System......................................................................... 14

13 Piping............................................................................................................. 15

14 Insulation for the Refrigerant Pipe ................................................................. 16

15 Wiring between the Wire and the Wiring Terminal ......................................... 16

16 Wiring of the Power Cord (single-phase) ....................................................... 18

17 Setting of External Static Pressure ................................................................ 19

18 Electric Installation ......................................................................................... 19

ⅣRated Working Conditions ..................................................................................... 20

ⅤError Analysis ......................................................................................................... 20

ⅥMaintenance........................................................................................................... 22

ⅥI Safety operation of flammable refrigerant. ........................................................... 23