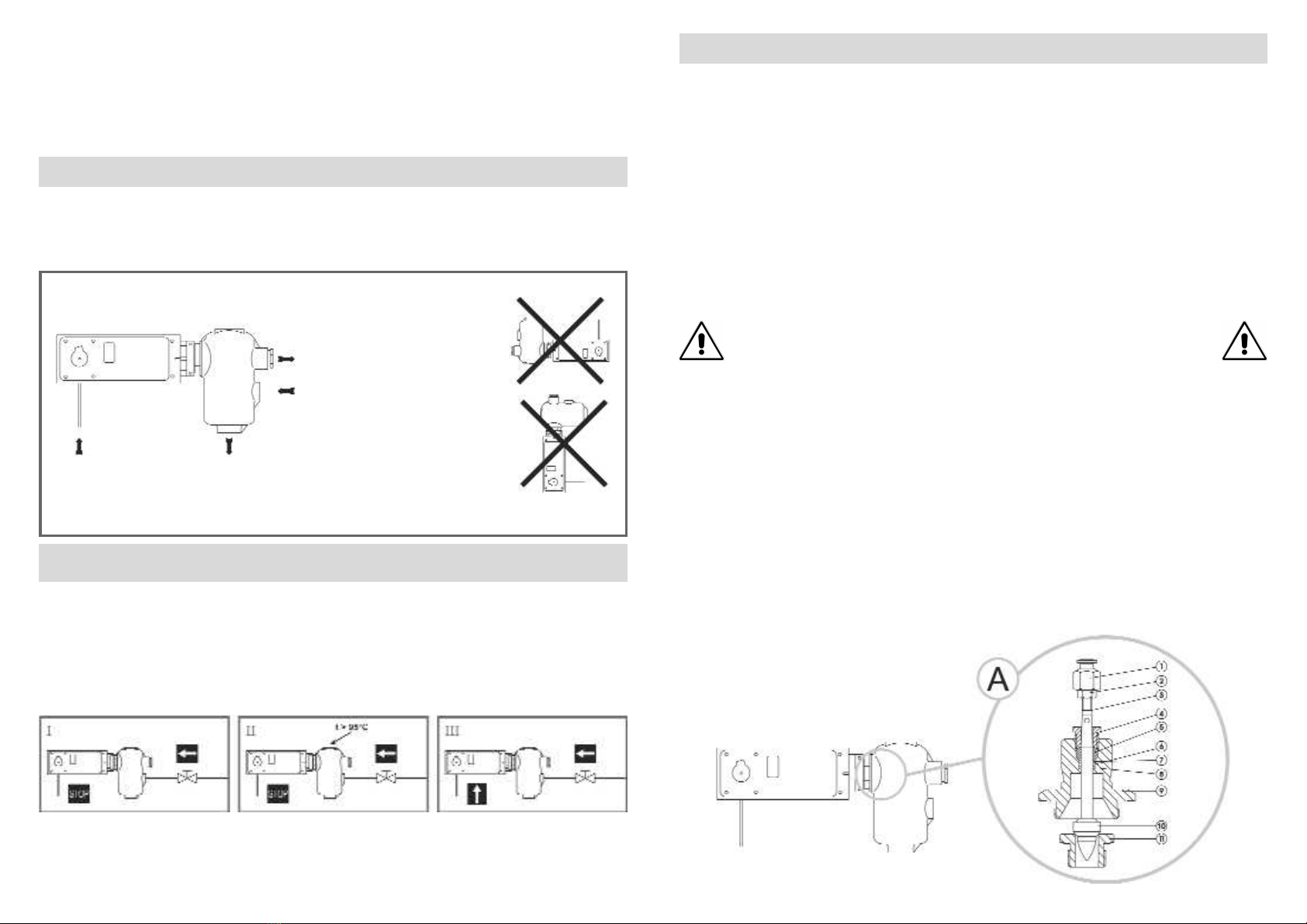

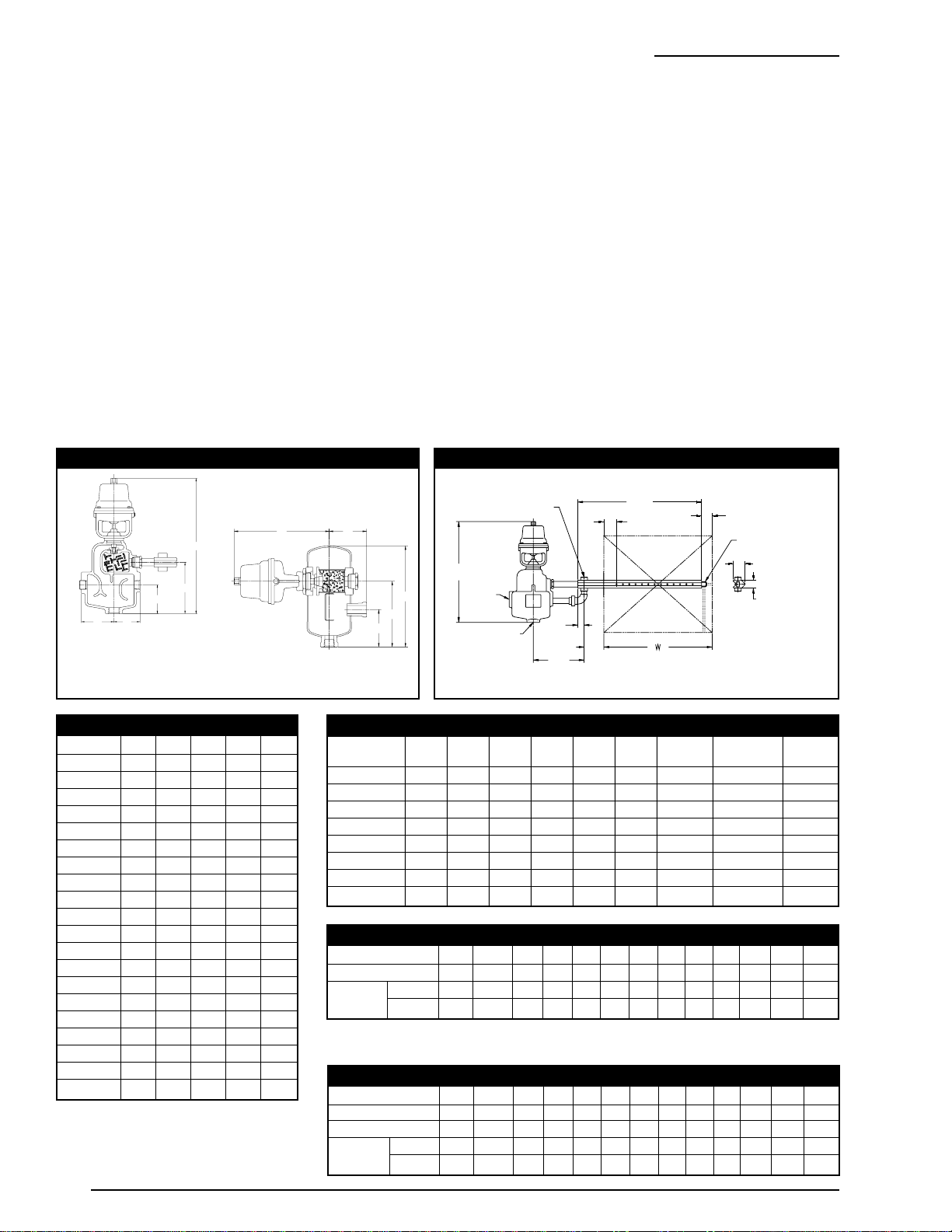

I. Austausch Ventil und Ventilsitz:

Anmerkung: bei Typ AM-1000 ist der Antrieb direkt auf das Luftbefeuchtergehäuse

aufgeschraubt (keine Verbindungsstück).

- Antrieb von Verbindungsstück abnehmen (A);

- Verbindungsstück (9) und alle verbundenen Teile abschrauben und entfernen;

- Ventilsitz (11) herausschrauben und erneuern;

-Stangeadapter (1) und Mutterstange (2) vom Ventilschaft (3) abschrauben;

- Stopfbüchse (4) herausschrauben und Packung (5), erste Dichtung (7),

Distanzscheibe (6) und zweite Dichtung (8) herausnehmen;

- Packungssatz erneuern durch Einsetzen der Teile (5, 6, 7 and 8) in umgekehrter

Reihenfolge, die Dichtungen (7 und 8) mit gewölbter Fläche nach unten;

- Stopfbüchse (4) wieder einschrauben;

- Einheit Ventilschaft (3) und Ventilsitz (11) einsetzen. Ventil (10) und Sitz (11)

sind geläppt;

- Stangeadapter(1) und Mutterstange (2) wieder auf Ventilschaft (3) aufschrauben;

- Verbindungsstück und alle verbundenen Teile wieder einschrauben (A).

-Antrieb mit Verbindungsstück (A) zusammenbauen. Ventilhub soll 19 mm

betragen.

- Dichten Abschluß des Ventils überprüfen. Wenn erforderlich,

Armstrong wegen der Einstellung des Antriebes kontaktieren.

Armstrong Steam Humidifiers can be delivered without operator, but in that case we do not have any responsibility for its assembly and its setup.

For detailed material specifications, approximate dimensions and weight, see Armstrong literature or consult your local Representative.

Armstrong Dampfluftbefeuchter sind auch ohne Antrieb lieferbar, wir übernehmen dann jedoch keine Verantwortung für die Montage und

Einstellung.

Für detaillierte Werkstoffangaben, Zubehör, Abmessungen und Gewichte, sehen Sie die Armstrong Datenblätter oder fragen Sie Ihre Armstrong-

Vertretung.

Les humidificateurs Armstrong peuvent être livrés sans servo-moteur ; dans ce cas, Armstrong se décharge de toute responsabilité concernant

l'assemblage et le réglage des opérateurs.

Pour toute spécification détaillée des matières, options, dimensions et poids, veuillez vous référer à la littérature Armstrong ou prendre contact

avec votre Représentant local.

Series EM-1000 & AM-1000

Steam Humidifiers

Dampfluftbefeuchter

Humidificateurs Armstrong

Humidificadores de Vapor

Stoombevochtigers

Umidificatori a Vapore

These instructions should be used by experienced personnel !

Diese Gebrauchsanweisung ist durch Fachpersonal zu benutzen !

Ces instructions devraient être utilisées par du personnel expérimenté !

¡Estas instrucciones deben ser utilizadas por personal experimentado !

Onderhoud uitsluitend uit te voeren door ervaren personeel !

Queste istruzioni devono essere utilizzate da personale esperto !

Model shown on the picture: BELEM-1100 - Die Abbildung zeigt das Modell BELEM-1100 - Photo: modèle BELEM-1100

Modelo mostrado en la fotografía: BELEM-1100 - Model op foto: BELEM-1100 - Modello in figura: BELEM-1100

Armstrong Stainless Steel Steam Humidifiers

Delivered with Inverted Bucket Steam Trap and "Y"-Type

Strainer, Assembled with Pneumatic or Electrical Actuator,

For Steam Distribution in Ducts (Through Manifolds)

Optional: Temperature Switch to Guarantee Discharge of Dry Steam Only

Armstrong Dampfluftbefeuchter aus Edelstahl mit

Glockenkondensatableiter und Y-Schmutzfänger,

Aufgebautem Pneumatischen oder Elektrischen Antrieb, zur

Einbringung von Dampf in Lüftungskanäle (durch Verteilrohre)

Option: Ein Thermostat Garantiert ausschließlich die Einbringung von Trockendampf

Humidificateur à Vapeur Armstrong en Acier Inoxydable. Livré avec Purgeur à Flotteur Inversé Ouvert et Filtre "Y". Monté avec

Servo-Moteur Pneumatique ou Électrique, Injection de Vapeur dans les Gaines de Conditionnement d'Air (Rampes d'Injection)

En option : Thermostat de Sécurité pour Garantir une Injection de Vapeur Sèche Uniquement

Humidificadores Armstrong en Acero Inoxidable. Se Entregan con Purgadores de Cubeta Invertida y Filtros Tipo "Y".

Montados con Actuador Neumático o Eléctrico. Para la Distribución de Vapor en Conductos (a Través de Manifolds)

Opcional: Termostato para Garantizar la Descarga de Vapor Seco Únicamente

Armstrong Stoombevochtigers uit Roestvrijstaal. Geleverd met Omgekeerde-Emmer Kondenspot en "Y"-Type Filter.

Voorzien van Pneumatische of Elektrische Aandrijving. Voor Stoomdistributie in Luchtkanalen (Middels Spreidingsbuizen)

Optioneel: Blokkeringsthemostaat Garandeert het Vrijkomen van Alleen Droge Stoom

Umidificatore a Vapore - in Acciaio Inossidabile. Fornito con Scaricatore di Condensa e Filtro di Linea a Y. Assemblato con

Attuatore Pneumatico o Elettrico. Per Distribuzione Vapore in Condotte o Centrali Trattamento Aria (Con Distributori)

Accessori opzionali: Termo-interruttore di Temperatura per Assicurare Distribuzione di Vapore Secco

Armstrong Steam Humidifiers can be delivered without operator, but in that case we do not have

any responsibility for its assembly and its setup.

Armstrong Dampfluftbefeuchter sind auch ohne Antrieb lieferbar, wir übernehmen dann jedoch keine

Verantwortung für die Montage und Einstellung.

Les humidificateurs à vapeur Armstrong peuvent être livrés sans servo-moteur. Dans ce cas, Armstrong se décharge

de toute responsabilité concernant l'assemblage et le réglage de ces opérateurs.

Los humidificadores de vapor Armstrong pueden entregarse sin actuador pero, en ese caso, no nos hacemos

responsables por su montaje y puesta en marcha.

Armstrong stoombevochtigers kunnen geleverd worden zonder aandrijving, in dat geval is Armstrong niet

aansprakelijk t.a.v. samenbouw en gebruikte instellingen

Gli umidificatori Armstrong possono essere forniti senza attuatori e solo eventualmente predisposti per il loro

assemblaggio. In tal caso la Armstrong declina qualsiasi responsabilità relativamente agli stessi attuatori, al loro il

successivo assemblaggio sugli umidificatori ed alla loro taratura operativa.

PRODUCT DESCRIPTION - PRODUKTBESCHREIBUNG - DESCRIPTION DU PRODUIT

DESCRIPCION DEL PRODUCTO - PRODUKT OMSCHRIJVING - DESCRIZIONE DEL PRODOTTO

Armstrong International S.A., Parc Industriel des Hauts-Sarts, 4040 Herstal - Belgium Ph: +32.4.240.90.90 Fax: +32.4.248.13.61

IOM-1041-B 10/2005 www.armstrong.be Printed in Belgium

I. Remplacement de l'ensemble siège-soupape :

Note: pour la série AM-1000, le servo-moteur est directement vissé sur le corps

de l'humidificateur (il n'y a pas d’accouplement).

- Retirer le servo-moteur de l’ensemble d’accouplement (bonnet) (A);

- Dévisser et enlever l’accouplement (9) et toutes les pièces qui y sont associées;

- Dévisser et remplacer le siège (11);

- Désolidariser l'accouplement de tige (1) et l'écrou (2) de la tige (stem) (3);

- Dévisser la presse étoupe (4) et enlever le bourrage (5), la première rondelle (7),

l’entretoise (6) et la deuxième rondelle (8);

- Remplacer l’ensemble de bourrage en replaçant les parties (5, 6, 7 and 8) dans

l'ordre contraire, les rondelles (7 and 8) doivent être placées avec le ressort vers

le bas. Revisser la presse étoupe (4);

- Remplacer la tige (3) et le siège (11). La soupape (10) et le siège (11) sont rodés

ensemble;

- Revisser l’accouplement de tige (1) et l'écrou (2) sur la tige (3);

- Revisser l’accouplement et toutes les pièces qui y sont associées (A);

- Remonter le servo-moteur sur l'ensemble d’accouplement (A). La course de la

vanne modulante doit être de 19 mm;

- S'assurer que la soupape soit bien étanche en position fermée.

Si nécessaire, consulter Armstrong pour le réglage du servo-moteur.

I. Sostituzione valvola e sede:

Nota: per la serie AM-1000, l'attuatore è avvitato direttamente sul corpo dell'

umidificatore (non c'è alcun bonnet).

- Scollegare l'attuatore dal bonnet (A);

- Svitare e smontare il bonnet (9) e tutte le parti ad esso annesse;

- Svitare e sostituire la sede (11);

- Smontare l'adattatore (1) ed il dado (2) dallo stelo (3);

- Svitare il premistoppa (4) ed estrarre la treccia di tenuta (5), il primo anello di

tenuta (7), il distanziale (6) ed il secondo anello di tenuta (8);

- Sostituire l'intero set di tenuta (5, 6, 7 e 8) in ordine opposto, le tenute (7 e 8)

devono essere posizionate con la molla rivolta verso il basso. Riavvitare il

premistoppa (4);

- Sostituire lo stelo (3) e la sede (11). La valvola (10) e la sede (11) sono lappate;

- Riavvitare l'adattatore (1) ed il dado (2) sullo stelo (3);

- Riavvitare il bonnet e tutte le parti ad esso annesse (A).

- Riassemblare l'attuatore con il bonnet (A). La corsa della valvola deve essere

di 19 mm;

- Assicurarsi che la valvola chiuda perfettamente. Se necessario

contattare la Armstrong o il distributore locale per l'eventuale taratura

dell'attuatore.

I. Cambio de válvula y asiento:

Nota: para la serie AM-1000, el actuador se rosca directamente en el cuerpo del

humidificador (no lleva bonete).

- Retire el actuador del conjunto de bonete (A);

- Afloje y retire el bonete (9) y todas las piezas sujetas a él;

- Desajuste y cambie el asiento (11);

- Retire el adaptador (1) y la tuerca (2) del vástago (3);

- Afloje el prensaestopas (4) y quite la empaquetadura (5) y el primer sello (7), el

separador (6) y el segundo sello (8);

- Cambie el juego de empaquetaduras colocando las piezas (5, 6, 7 y 8) en orden

inverso; los sellos (7 y 8) deben quedar con el muelle mirando hacia abajo. Vuelva

a ajustar el prensaestopas (4);

- Cambie el conjunto de vástago (3) y asiento (11). La válvula (10) y el asiento

(11) están pulidos;

- Vuelva a ajustar el adaptador (1) y la tuerca (2) en el vástago (3);

- Coloque nuevamente el bonete y todas las piezas sujetas a él (A);

- Monte el actuador con el conjunto de bonete (A). La válvula deberá tener un

desplazamiento de 19 mm;

- Asegúrese de que la válvula cierra firmemente. Si fuera necesario,

consulte con Armstrong para la puesta en marcha del actuador.

Vervangen van klep en klepzitting:

N.B.: voor de serie AM-1000 is geen bonnet benodigd. De aandrijving is direkt op het

huis geschroefd.

- Verwijder de aandrijving van de klepassembly (A);

- Verwijder het koppelstuk (9) middels losschroeven en alle daaraan geassembleerde

onderdelen;

- Schroef de zitting (11) los en vervang deze ;

- Verwijder de klepsteel moer (1) en de klepsteel borgmoer (2) van de klepsteel (3);

- Schroef het pakkingsdrukstuk (4) los en verwijder de pakking (5) en de eerste

afdichting (7), de dichtingsring (6) en de tweede afdichting (8);

- Vervang de complete pakkingset door nieuwe onderdelen (5, 7, 6 and 8) in

omgekeerde volgorde te monteren, de afdichtingen (7 en 8) moeten geïnstalleerd

worden met de veer naar beneden gericht. Zet pakkingsdrukstuk (4) weer vast;

- Vervang de klepsteel (3) en zitting (11). Regelventiel (10) en zitting (11) zijn gepolijst;

- Schroef de klepsteel moer (1) en de klepsteel borgmoer (2) op de klepsteel (3);

- Schroef de bonnet en alle geassembleerde onderdelen terug op het huis (A).

- Monteer de aandrijving met de klepassembly (A). De slag van het regelventiel moet

19 mm zijn;

- Controleer of het regelventiel goed sluit. Indien nodig neemt u contact op

met uw Armstrong vertegenwoordiging voor de juiste instelling.

I. Valve and Seat Replacement:

Note: for the series AM-1000, the operator is directly screwed on the humidifier’s

body (there is no bonnet).

- Remove the operator from the bonnet assembly (A);

- Unscrew and remove the bonnet (9) and all the parts assembled to it;

- Unscrew and replace the seat (11);

- Disassemble the stem adapter (1) and the stem nut (2) from the stem (3);

- Unscrew the packing gland (4) and remove the packing (5) and the first seal (7),

the seal spacer (6) and the second seal (8);

- Replace the packing set by putting the parts (5, 6, 7 and 8) in the opposite order,

the seals (7 and 8) should be with the spring facing downward. Screw back the

packing gland (4);

- Replace the stem (3) and seat (11) assembly. Valve (10) and seat (11) are

lapped;

- Screw back the stem adapter (1) and the stem nut (2) on the stem (3);

- Screw back the bonnet and all the parts assembled to it (A);

- Assemble the operator with the bonnet assembly (A). The stroke of the valve

should be 19 mm;

- Make sure that the valve is closing tightly. If necessary, consult

Armstrong for operator set-up.