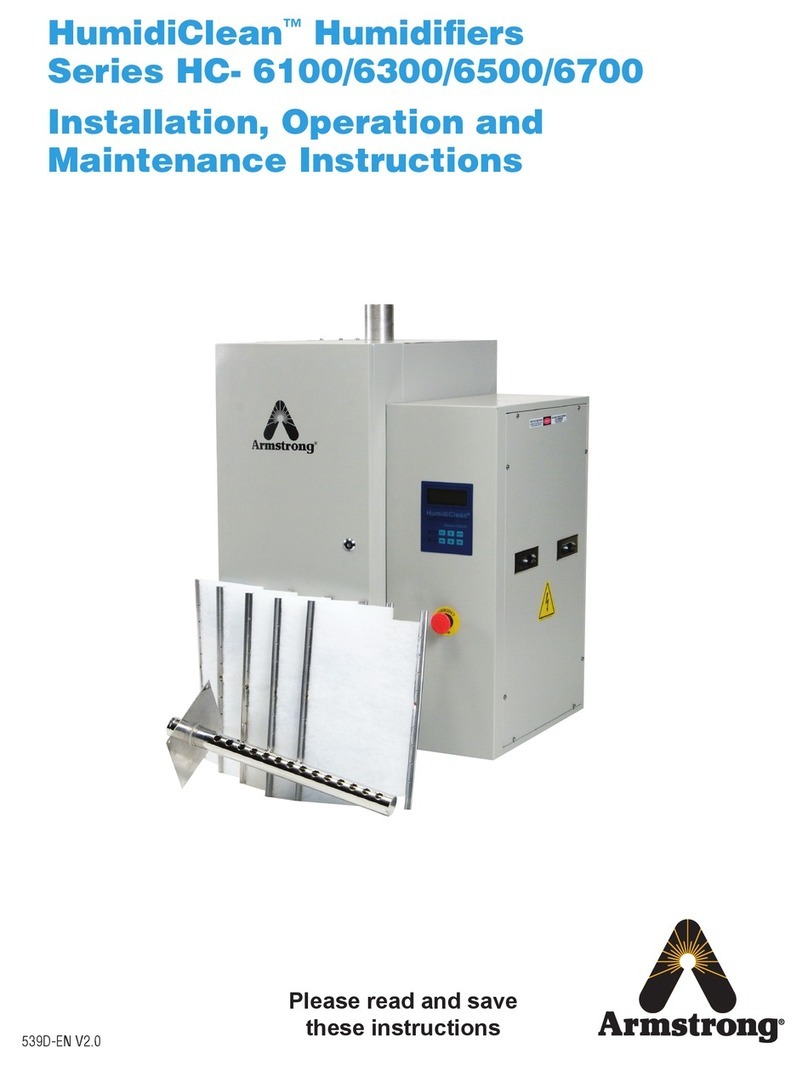

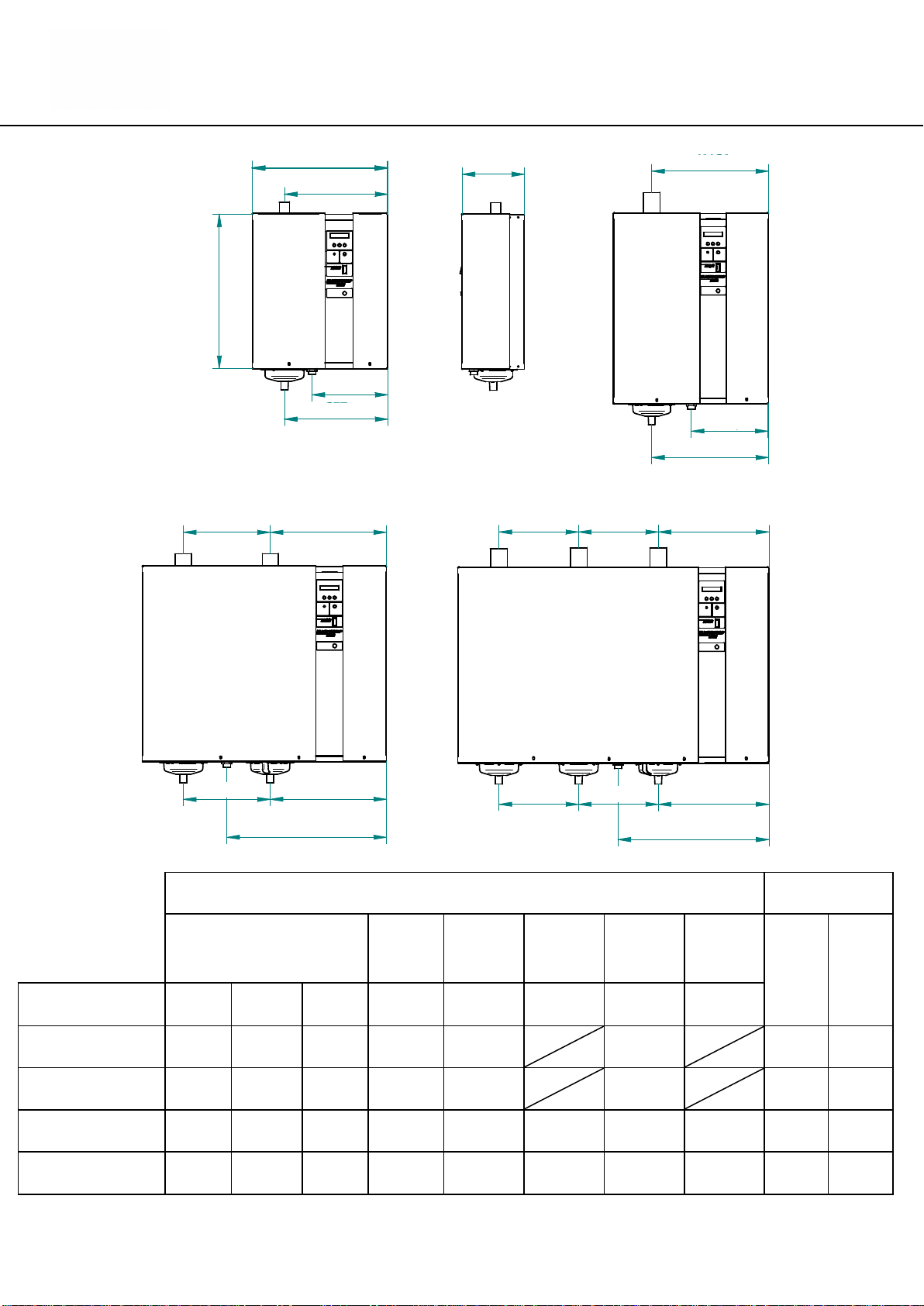

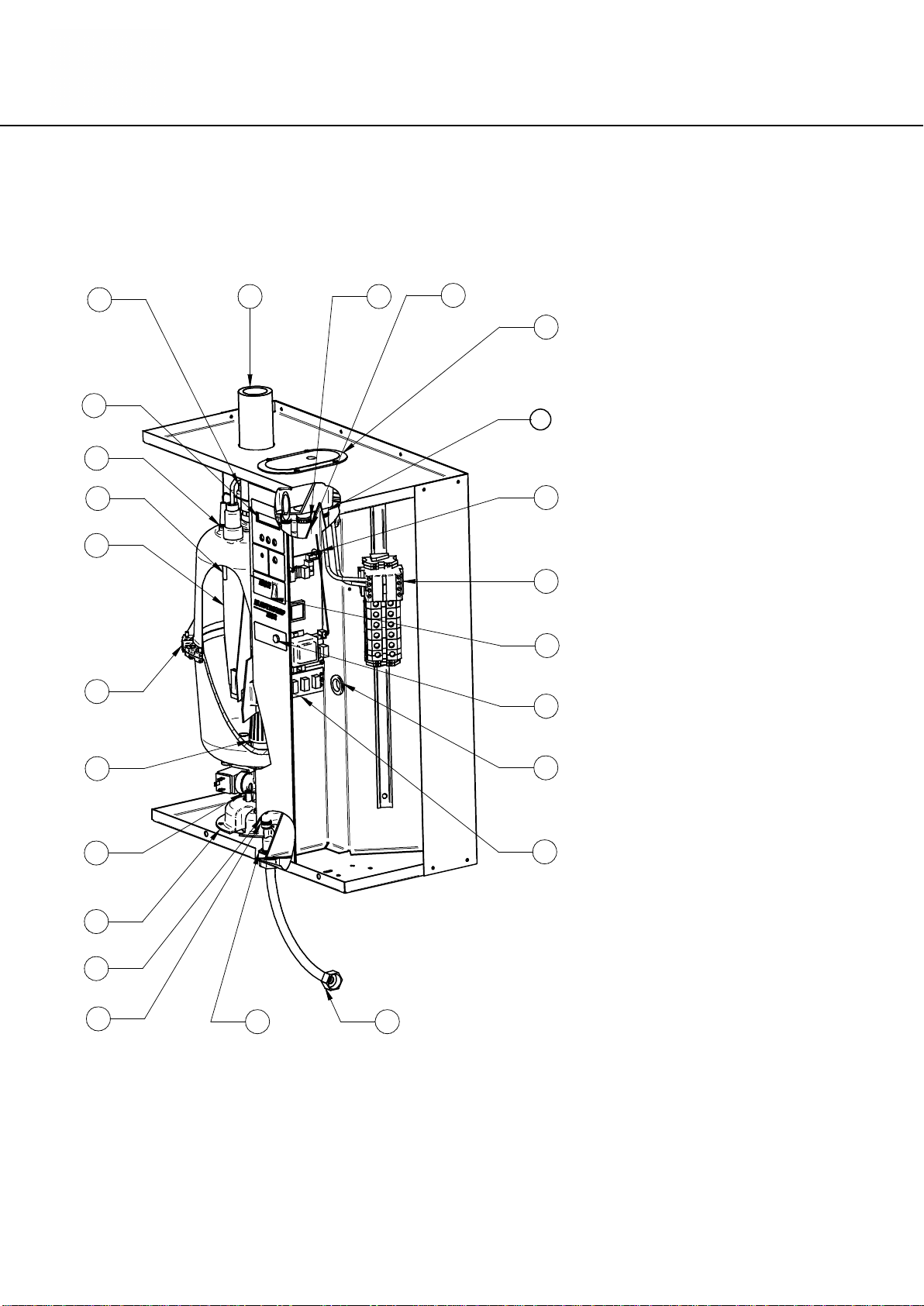

4 Pictures for illustrating purposes only

SERIES EHU-750 HUMIDIFIER

Safety information

GENERAL

This manual contains all details necessary for the planning and installation of the EHU-750

humidifier. In addition commissioning and maintenance details are included.

The manual is intended for use by engineers and properly trained technical personnel.

Maintenance, servicing or repair work must only be carried out by suitable skilled and

qualified personnel, the customer must be responsible for ensuring their suitability.

Any risks or hazards, especially when working from ladders or towers should be identified by

a skilled and Health and Safety representative and effective control measure put in place.

No liability will attach to the Distributor if any damage, injury or accident is attributable to

inattentive, inappropriate, negligent or incorrect operation of the machinery whether or not

caused deliberately. Always isolate all electrical and water supplies before commencing any

maintenance.

Every effort has been made to ensure details contained in this manual are correct, however,

in view of the wide range of conditions experienced in air handling systems, the information

provided should only be used as a guide. Please contact your Agent if any doubt.

Correctuse

EHU-750 humidifiers are ONLY intended for use with air handling systems or direct air

humidification. ANY OTHER APPLICATION IS NOT CONSIDERED USE FOR THE

INTENDED PURPOSE. THE MANUFACTURER CANNOT BE MADE LIABLE FOR ANY

DAMAGE RESULTING FROM INCORRECT USE.

Water

Series EHU-750 humidifiers are designed to be used with mains, demineralized R/O or

softened water. On no account attempt to introduce any other fluid or chemical into the

system. Water supply should not exceed 6.0 bar and installation should comply with local

regulations. If the water pressure exceeds 6.0 bar, a water regulator valve must be used.

Electricity

All work concerned with electrical installation MUST only be performed by skilled and

qualified technical personnel (eg electrician or technicians with appropriate training). The

customer MUST be responsible for ensuring their suitability.

It is the duty of the installer to ensure that suitable sized cables and MCB protection is

provided. Please observe the local regulations concerning the provision of electrical

installations.

Warranty

A one year warranty term—cost and labor—is applicable to the parts of the EHU-750 to the

exception of the usual consumable parts (valves, cylinders or parts of cylinders) provided our

recommendations of use & maintenance have been adhered to. Failure to specify and fit

original parts and accessories will invalidate our warranty.

NOTE

The manufacturer’s policy is one of continuous research and development. He therefore

reserves the right to amend without notice the specifications given in this document.

The photographs are for illustrating purposes only.