3

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit armstronginternational.com for up-to-date information.

Armstrong International

North America • Latin America • India • Europe / Middle East / Africa • China • Pacific Rim

armstronginternational.com

1.2 IMPORTANT REMARKS

GENERAL

Maintenance, service, repairs, as well as the study of the risks and dangers

associated with these operations must be carried out by qualified, competent, and

authorized personnel.

- Make sure that all risks or dangers are defined beforehand by an authorized person,

especially at elevated heights.

- We also recommend installing a security perimeter.

- Make sure that the power supply is switched off before performing maintenance.

- Please periodically tighten all the connection terminals of the power cable.

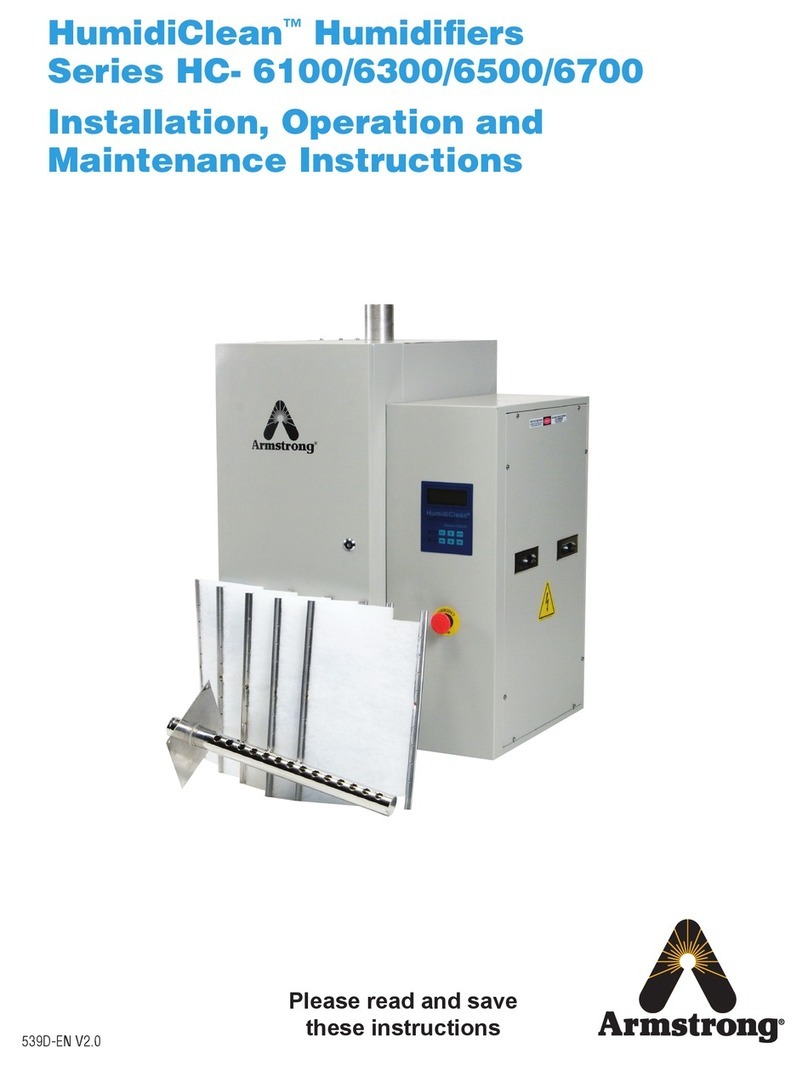

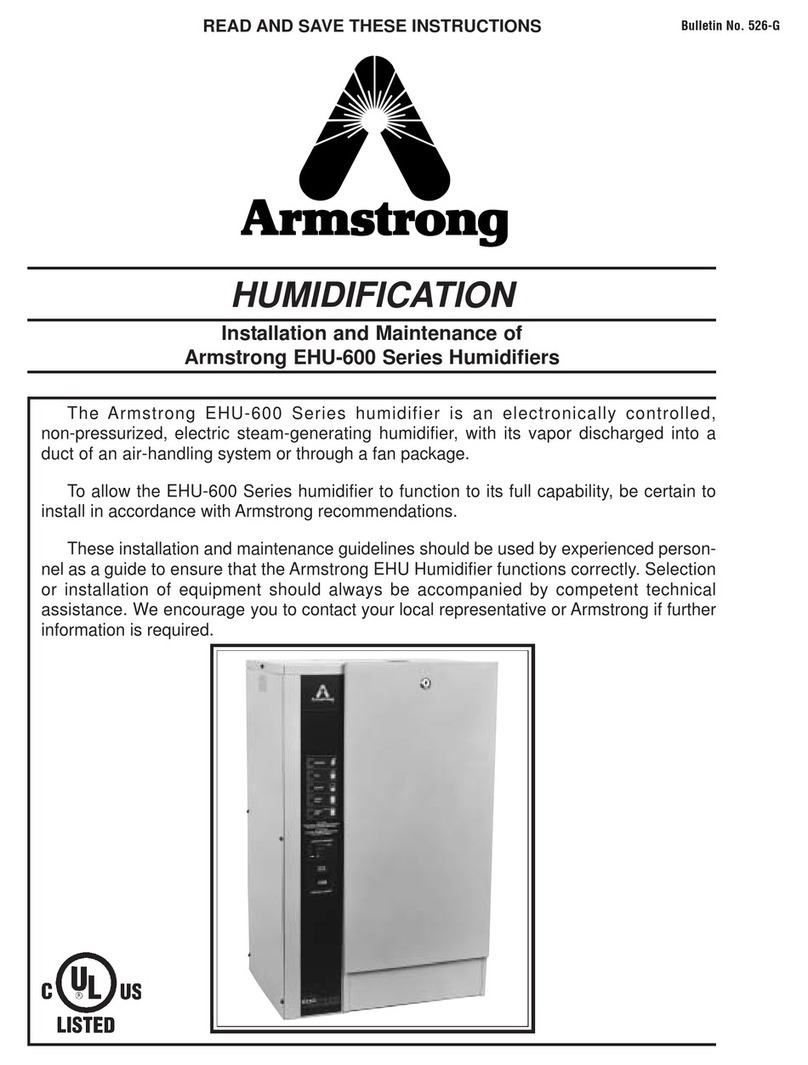

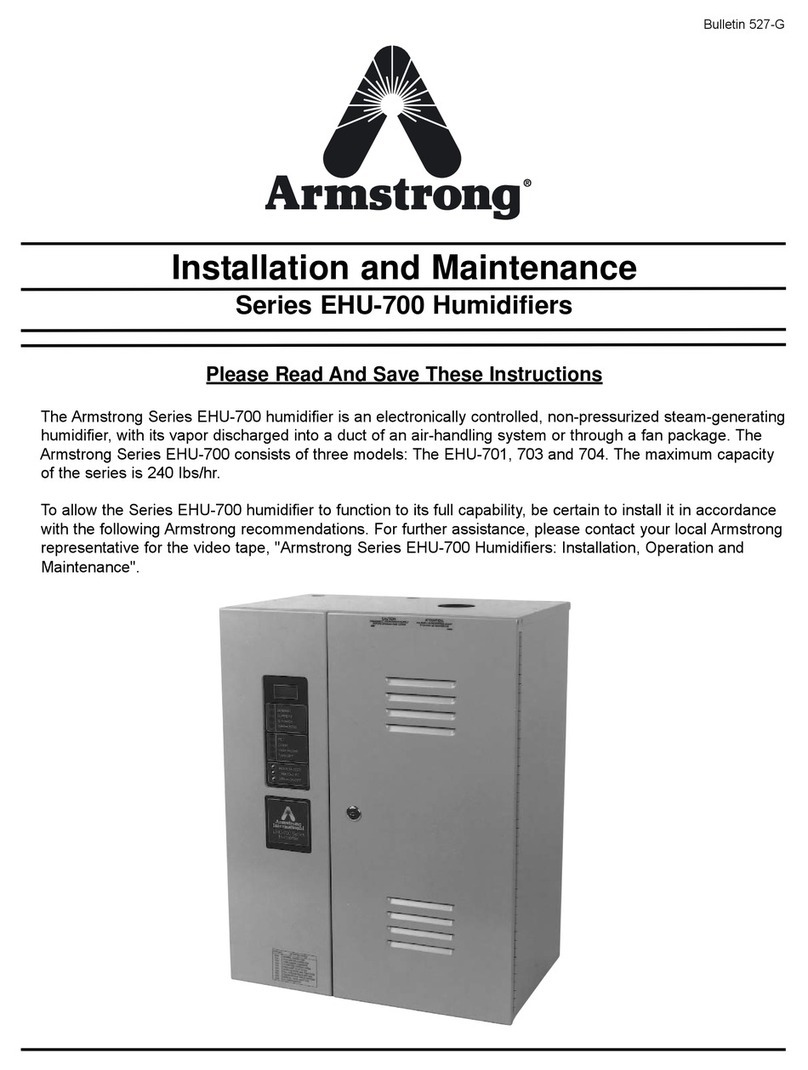

INTENDED USE

This device manufactured by Armstrong is intended solely for humidification purposes,

discharged into the duct of an air-handling system or through a fan package. The user

undertakes to use it according to the safety instructions given in this manual.

Improper use could result in serious hazards and damages to the user, third parties,

and materials.

STORAGE &

MAINTENANCE

The device must be stored in a dry, frost-free place, protected from shocks and

vibrations. Handling must be carried out by at least two people or suitable lifting

equipment.

WATER

Steam humidifiers can be used with potable, demineralized, or softened water. It is

absolutely forbidden to inject a chemical into the hydraulic system. Make sure that

the water supply pressure does not exceed 87 psi (5.9 bar). Always be careful that the

installation meets all state and local building codes.

ELECTRICITY

The user ensures that electrical installation will be carried out by an authorized

technician in this field. The installer must provide the correct cable section as well as

the thermal-magnetic circuit breaker protection, adapted to the regulations in place in

the country of installation.

WARRANTY

Armstrong International, Inc. (“Armstrong”) warrants to the original user of those

products supplied by it and used in the service and in the manner for which they are

intended, that such products shall be free from defects in material and workmanship

for a period of one (1) year from the date of installation, but not longer than 15

months from the date of shipment from the factory, [unless a Special Warranty Period

applies, as listed below]. This warranty does not extend to any product that has been

subject to misuse, neglect or alteration after shipment from the Armstrong factory.

Except as may be expressly provided in a written agreement between Armstrong

and the user, which is signed by both parties, Armstrong DOES NOT MAKE ANY

OTHER REPRESENTATIONS OR WARRANTIES, EXPRESS OR IMPLIED, INCLUDING,

BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR ANY

IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

LIABILITY

IN NO EVENT SHALL ARMSTRONG BE LIABLE FOR SPECIAL, DIRECT, INDIRECT,

INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING, BUT NOT LIMITED TO,

LOSS OF USE OR PROFITS OR INTERRUPTION OF BUSINESS. The Limited Warranty

and Remedy terms herein apply notwithstanding any contrary terms in any purchase

order or form submitted or issued by any user, purchaser, or third party and all such

contrary terms shall be deemed rejected by Armstrong.