4Designs, materials, weights and performance ratings are approximate and subject to

change without notice. Visit armstronginternational.com for up-to-date information.

Warning: Do not operate the supplied humidifier in combustible or explosive surroundings.

Warning: Do not operate the supplied humidifier if there is any damage to the cabinet or any components in humidifier

are damaged.

Warning: The main switch should be a connection breaker which has over current and leakage current protecting

functions per code EN60947-3 or EN60947-2 if point gap required by EN60947-3 can be fulfilled.

4. Physical environment and operating conditions

•Ambienttemperature+4°C~+38°C(40°Fto100°F)

•Humidity=50%at40°C(104°F),=90%at20°C(68°F)

•Altitude=1000m(abovemeansealevel)(3300ft)

5. Transportation and storage conditions

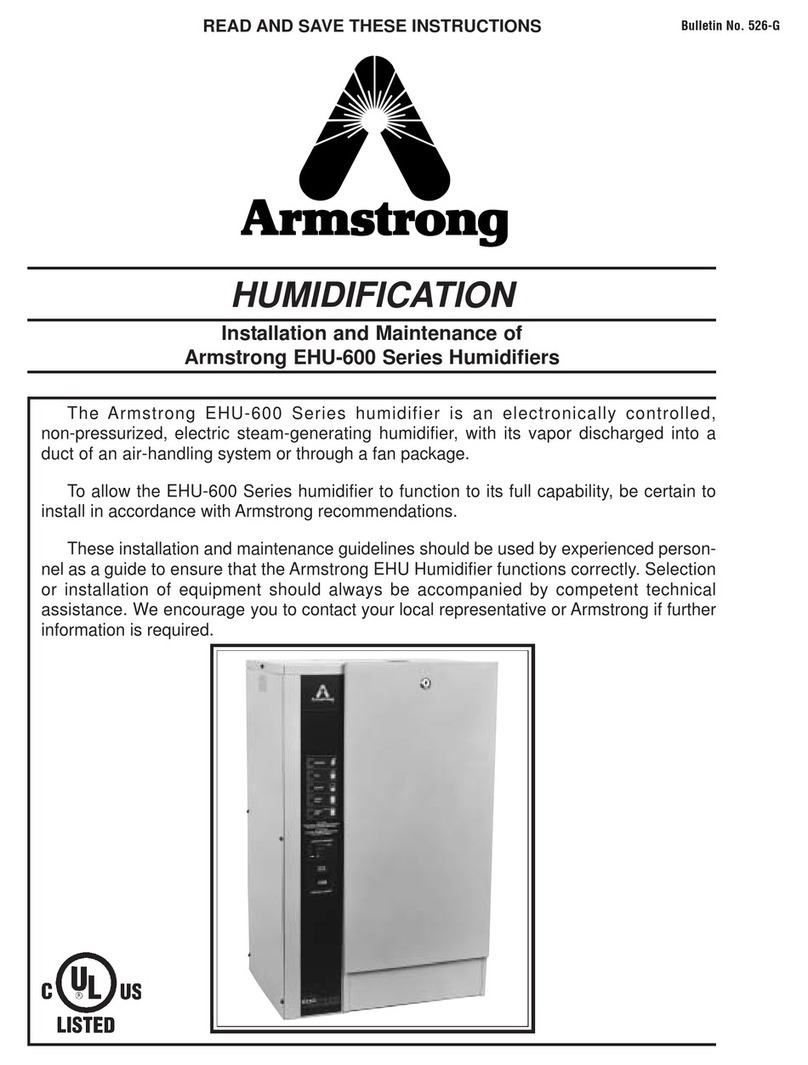

Electrical equipment shall be designed to withstand, or suitable precautions shall be taken to protect against, the

effectsoftransportationandstoragetemperatureswithinarangeof-25°Cto+55°C(-15°Fto130°F)andfor

shortperiodsnotexceeding24h,upto+70°C(160°F).Suitablemeansshallbeprovidedtopreventdamagefrom

humidity, vibration and shock.

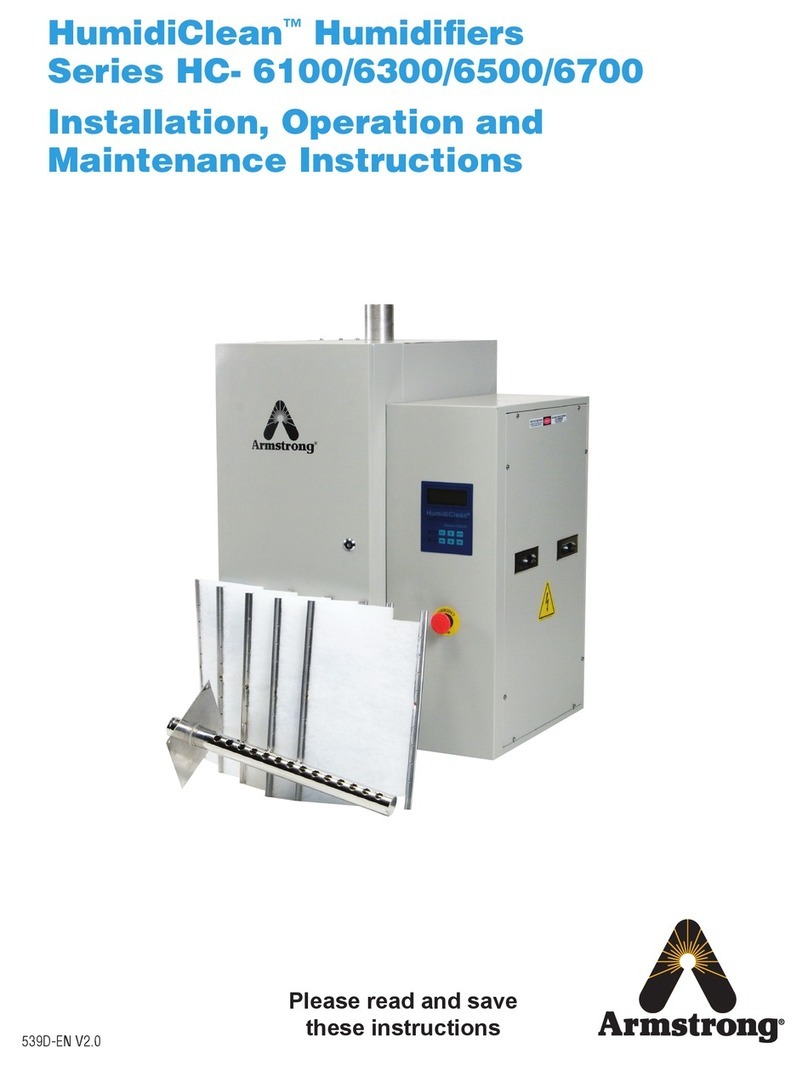

6. Requirements

Thesupplydisconnectingdevice(i.e.aswitch-disconnect,adisconnectusedincombinationwithswitchingdevices,

oracircuit-breaker)shallfulfillallofthefollowingrequirements:

•IsolatetheelectricalequipmentfromthesupplyandhaveoneOFF(isolated)andoneONpositiononly,clearly

markedwith“O”and“I”(symbols60417-2-IEC-5008and60417-2-IEC-5007,see10.2.2),withtheactuating

directionsinaccordancewithIEC60447.Circuit-breakerthat,inaddition,hasareset(tripped)positionbetween

“O” and “I” are also deemed to satisfy this requirement.

•HaveavisiblegaporapositionindicatorwhichcannotindicateOFF(isolated)untilallcontactsareactually

open and there is an adequate isolating distance between all the contacts in accordance with IEC 60947-3.

•BeprovidedwithameanspermittingittobelockedintheOFF(isolated)position(e.g.bypadlocks).When

locked, remote as well as local closing shall be prevented.

•Disconnectallliveconductorsofitspowersupplycircuit.However,forTNsupplysystems,theneutral

conductor may or may not be disconnected. It is noted that in some countries, disconnection of the neutral

conductor(whenused)iscompulsory.

•Thehandleofthesupply-disconnectingswitchshallbelocatedbetween0.6mand1.7m(2ft.and5-1/2ft)

above the servicing level.

•Thedisconnectingswitchmusthaveovercurrentandoverloadprotectingfunctionsandinitializethemaslow

as possible under normal running.

•Thedisconnectingswitchshouldhaveabreakingcapacitysufficienttointerruptthelargestnormalrunning

currentofloads.Thebreakingcapacityrequiredshouldbeselectedaccordingtothetableonpage8.