AA

9

H\

Armstrong No. 800 BVSW Series

Inverted Bucket Air Traps

-

A~~~Q9~~

Installation, Operation

&

Maintenance Data

PRELIMINARY

Moisture is always present in compressed

air. Oil is

almost

always present at some

points in a compressed air system.

Moisture and oil must be removed from

the system for efficient operation and

long life of gaskets, hoses, and air tools.

Efficient moisture and oil removal that

will forestall trouble requires:

directed by the equipment manufac-

turer. Traps should be accessible to

the maintenance man. If lack of

headroom prevents trap installation

below a receiver, install as shown in

Fig. 2. If trap must be installed

above the dram connection, an inter-

nal check valve or swing check is us-

ed to prevent trap prime loss when

air pressure drops.

pipe cuttings, scale, and dirt. Last of

all, screw the trap into position.

Aftercoolers to bring the compressed

air down to ambient or room

temperature.

2.

Separators to knock down suspend-

ed droplets of water or fog.

First install piping and shut-off

valve ahead of trap, then blow down

the

line

at full pressure to remove

A

4.

Caution

-

since the trap operates

with the body full of water, do not in-

stall where freezing can occur unless

proper non-freeze precautions are

taken.

Separators are installed downstream

from aftercoolers or in an air line

near point of use, or both. Note

-

air

traps are not separators.

Air Traps to discharge the liquid

from the system with a minimum

loss of air.

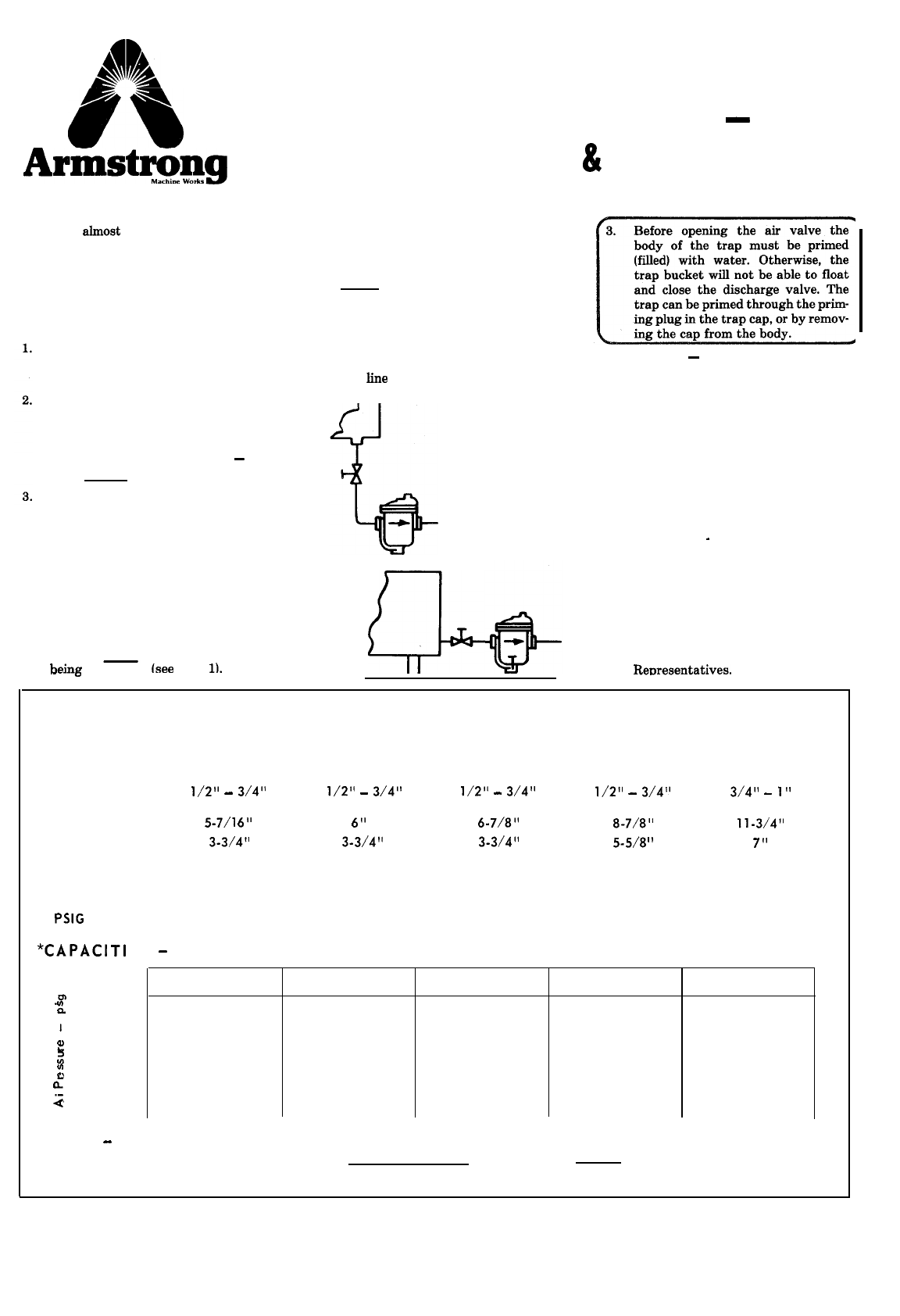

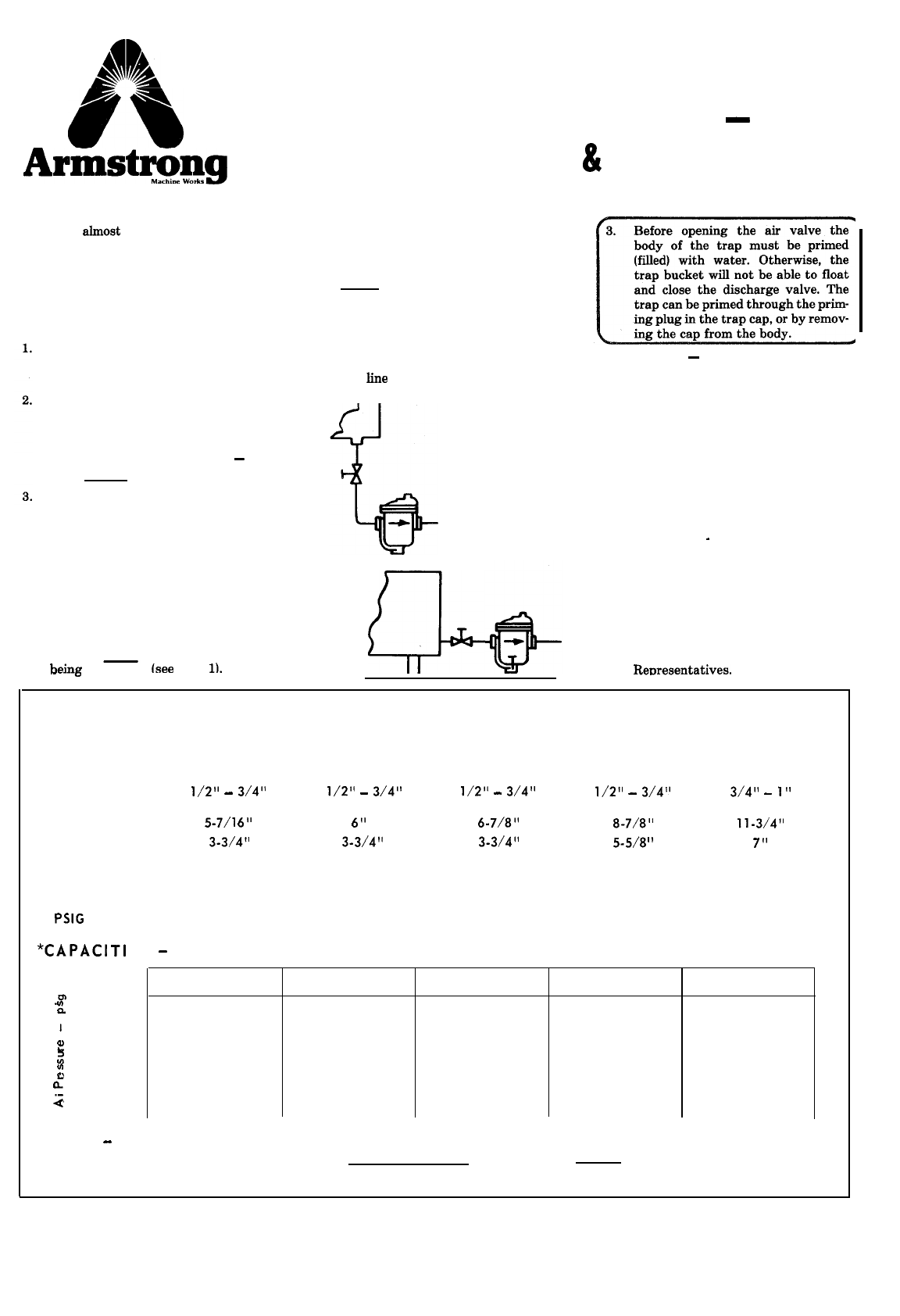

Fig. 1

TRAP INSPECTION

AND MAINTENANCE

1.

Check trap operation periodically.

Determine that body is full of water

(trap is primed).

2.

If examination shows heavy coating

.

To

get the best results from Armstrong

Inverted Bucket Air Traps, please

observe the recommendations given

below.

INSTALLATION

1.

Inverted Bucket Air Traps should be

installed below and close to the unit

heirw

drained

lsee

Fie.

II.

or as

Fig. 2

x-

of oil

on mechanism, arrange to clean

at regular intervals. Clean body and

cap as well as mechanism.

3.

Examine mechanism at least once a

year to determine tightness of valve

and seat and if any parts require

replacement. If repairs are

necessary, contact your Armstrong

Renresentatives.

-

----o

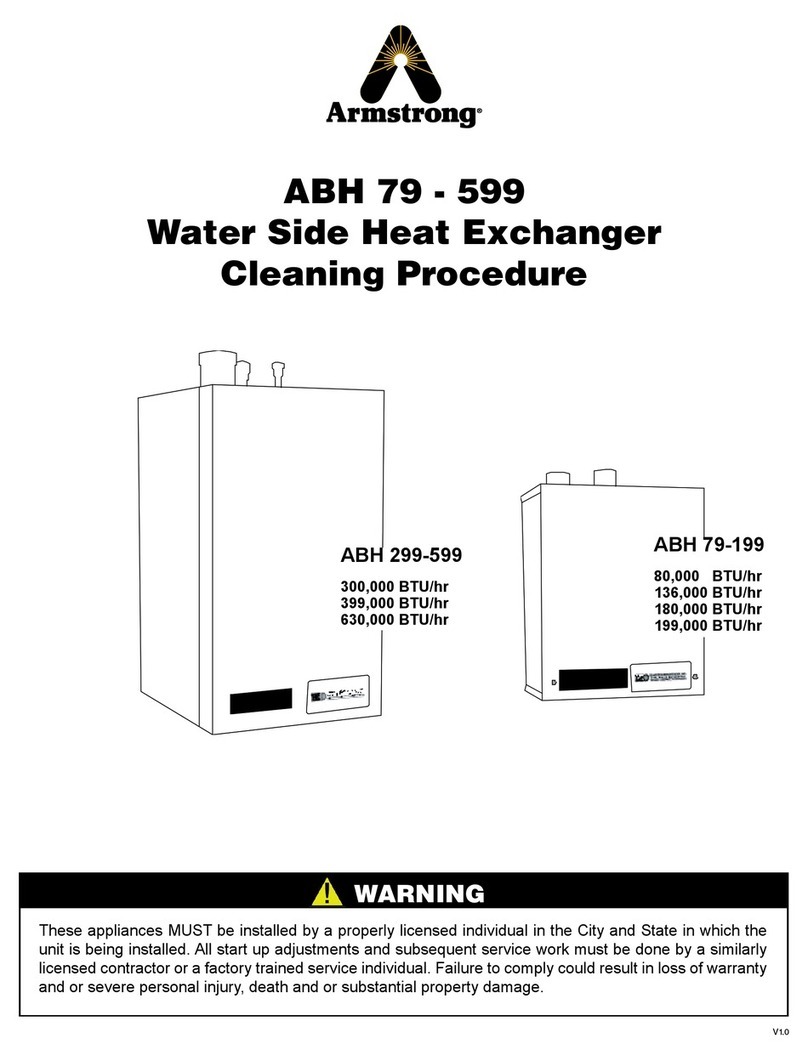

PHYSICAL DATA

MODEL

CONNECTION

PIPE

CONNECTION

SIZE

HEIGHT

DIAMETER

WEIGHT

MAXIMUM

OPERATING

PRESSURE

NO. 800 NO. 801

HORIZONTAL RIGHT ANGLE

l/2”

-

3/4”

l/2”

-

3/4”

S-7/1

6” 6”

3-3/4” 3-3/4”

5 Ibs. 5 Ibs.

NO.811

HORIZONTAL

l/2”

-

3/4”

6-7/8”

3-3/4”

6 Ibs.

NO. 812

HORIZONTAL

l/2”

-

3/4”

8-7/8”

5-5/8

”

15 Ibs.

NO.813

HORIZONTAL

3/4”

-

1”

l l-3/4”

7”

27 Ibs.

150 150 250 250 250

PSIG

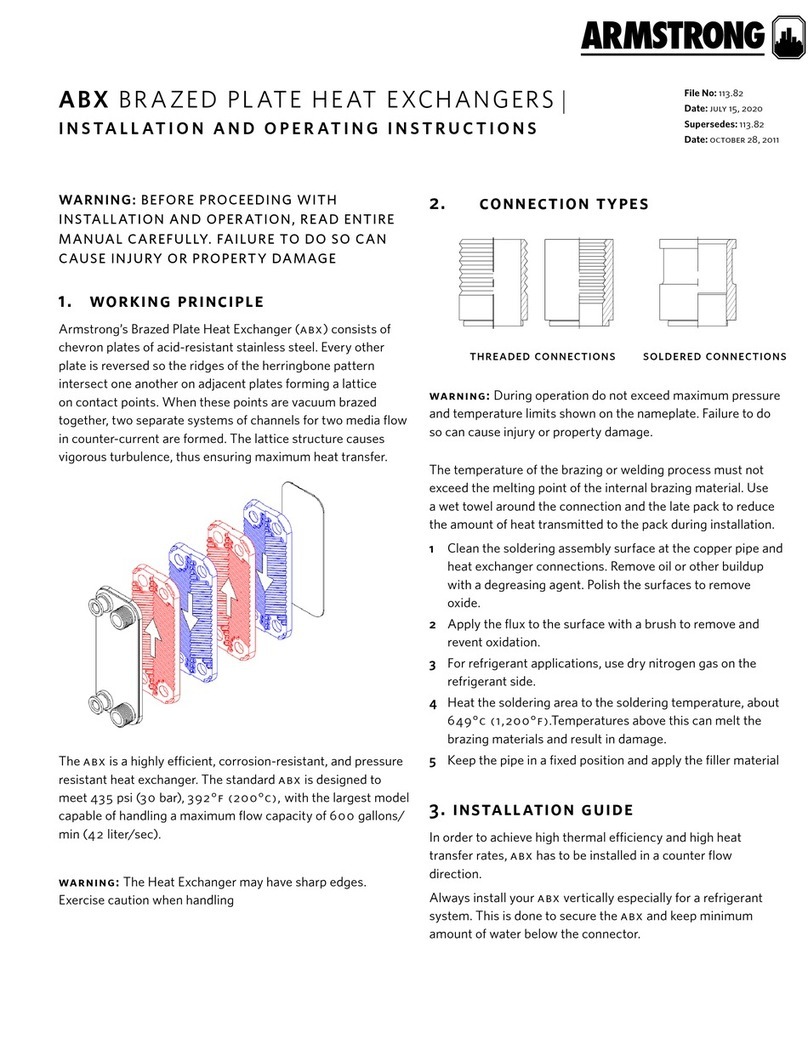

*CAPACI

TI

ES

-

Pounds of Water Per Hour

NO. 800 NO. 801 NO.811 NO. 812 NO. 813

.E”

2

15 1300 1300 2400 3500 9000

I

30 800 800 1800 3200 7000

280 1300 1300 1300 2000 6500

:

ul

125 1300 1300 1600 2500 6500

0

a’

150 1000 1000 1400 1800 5500

_

2

250 1700 1800 5000

*Capacity

-

Mere water handling capacity is not the whole story. The No.813 is the smallest inverted bucket air trop with

sufficient power to give dependable service when heavy oil is present with the water. Do not use smaller traps if heavy oil

is present in your air system.