Page 2 of 3

For other Armstrong instructions pertaining to 4360D & 4380

pumps please refer to: Installation & Operating – File: 43.64,

Shaft Sleeve Replacement – File: 6042.25, Mechanical Seals

Kits – File: 6040.60”

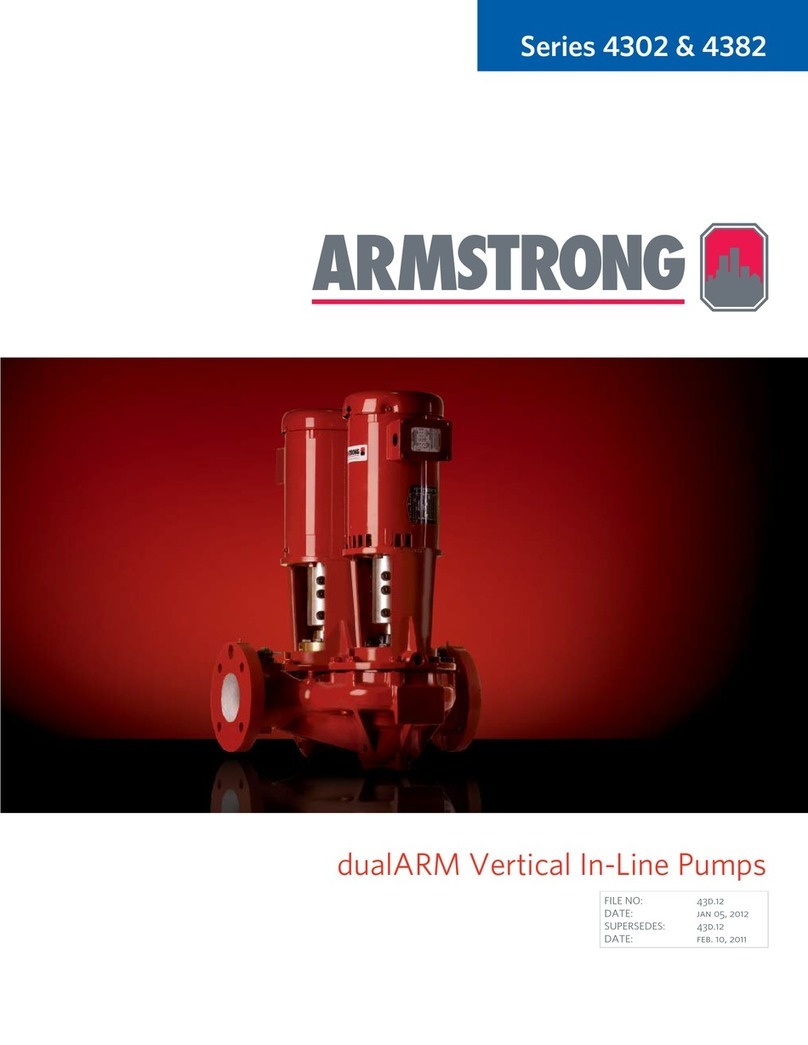

The Series 4360D and 4380 pumps are motor mounted or

“close coupled” type Vertical In Line pumps, on which are

mounted vertical shaft-down ball bearing motors. Each pump

and motor unit is pipe mounted and as such relies on the pip-

ing only for support. The piping support is designed for the

weight of the piping, liquid, pump and motor and other pipe

fittings. The pumping unit should not be independently secured

to the building structure. If the pump is mounted separately to

any structure, the pump must be isolated from the piping with

flexible piping connections. For units with larger motors it is

advisable to install a permanent device for lifting the rotating

assembly out of the pipe mounted casing to service the unit.

BREAKDOWN PROCEDURES:

1. ELECTRICAL WIRING

If the pump and/or motor assembly is to be serviced on a

bench, the motor wiring must be disconnected.

2. ISOLATION VALVES

If the system is not drained: Ensure that the suction and

discharge piping isolation valves are closed. Remove drain

plug [105] from the bottom of the casing and drain the

pump.

3. PREPARE ASSEMBLY FOR REMOVAL

Secure the motor [10], by lifting straps, to an overhead

chainfall or similar lifting device. The device must be de-

signed to lift the weight of the unit safely. Raise the lifter to

bring the lifting straps taut. Disconnect the flush/vent tub-

ing assembly and place carefully to one side. Remove the

casing capscrews and washers [103 & 104]. Pry bars may

then be inserted between the casing [100] and adapter

[40]. Care should be taken not to apply pressure to the

outside diameter of the adapter, to prevent possible break-

age, outside pressure should be on the casing only.

4. REMOVE ROTATING ASSEMBLY

The rotating assembly (Motor, adapter and impeller [10,

40 & 80]) may now be lifted out of the casing.

5. ROTATING ASSEMBLY NOTES

The impeller [80] is fastened directly to the motor shaft and

must be removed in order to replace the mechanical seal

assembly [60/62]. This may be accomplished on a safe sur-

face near the installation or, more conveniently, on a work

bench.

6. IMPELLER CAPSCREW

The impeller [80] should be prevented from rotating while

the impeller capscrew [86] is loosened. A heavy screwdriver

may be inserted between the impeller blades to enable the

impeller capscrew [86] to be backed off with a socket

wrench. Remove the impeller capscrew and washer

[86 & 83].

7. PUMP IMPELLER

Using wheel pullers, with the jaws behind the rear shroud of

the impeller [80] (Behind a vane at each side) pull the impel-

ler free of the pump shaft. Impellers that are difficult to re-

move may be loosened by heating the impeller hub with a

torch during the pulling process. Remove the impeller from

the motor shaft. Note the impeller key and shaft sleeve

spacer [71]. Remove both for storage.

8. REMOVE MECHANICAL SEAL FROM MOTOR

SHAFT

The mechanical seal spring usually comes free with the

impeller. The mechanical seal rotating element [62] must be

pried loose with pry bars or screwdrivers, placed under each

side of the seal drive band. Leverage is applied against the

adapter. Once loosened, the seal may be pulled free of the

shaft.

Do not damage the carbon face when removing the rotating

assembly. It may be needed for analysis if seal failure

investigation is required.

9. REMOVE SEAL SEAT FROM ADAPTER

The mechanical seal seat [60], typically O-ring or L-cup

mounted Silicon Carbide material, is pried loose from the

recess in the adapter. If the seat cannot be removed in this

manner, remove the motor capscrews [44] and separate the

adapter [40] from the motor [10]. A screwdriver may then be

used to push the seat out of the adapter from the rear.

10. REMOVE OLD CASING GASKET

The former casing gasket [101] should be scraped from the

casing and adapter, leaving clean surfaces for the new gas-

ket. (A standard putty knife and wire brush are useful for this

purpose)

Exercise extreme care when handling power wiring. Ensure

that the fuses are removed or breaker disconnected in the

power line to the motor. Power disconnect should be within

sight of the pump being serviced and tagged with the reason

for disconnection.

CAUTION