Santiago

English

26 05060120 00 11/05/2011

Installation and Operation Manual

TABLE OF CONTENTS

ILLUSTRATIONS................................................................................................................. 1

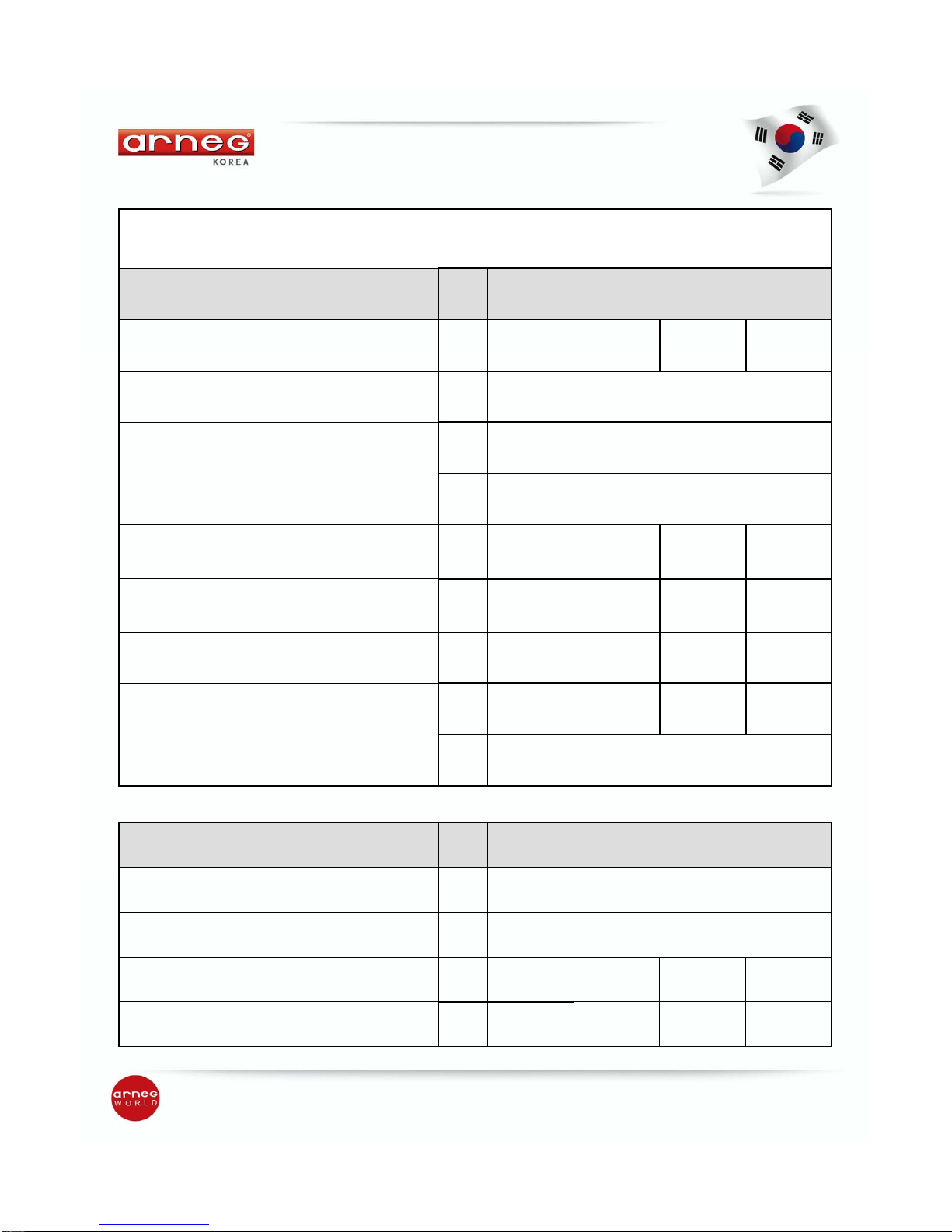

Technical data...................................................................................................................... 12

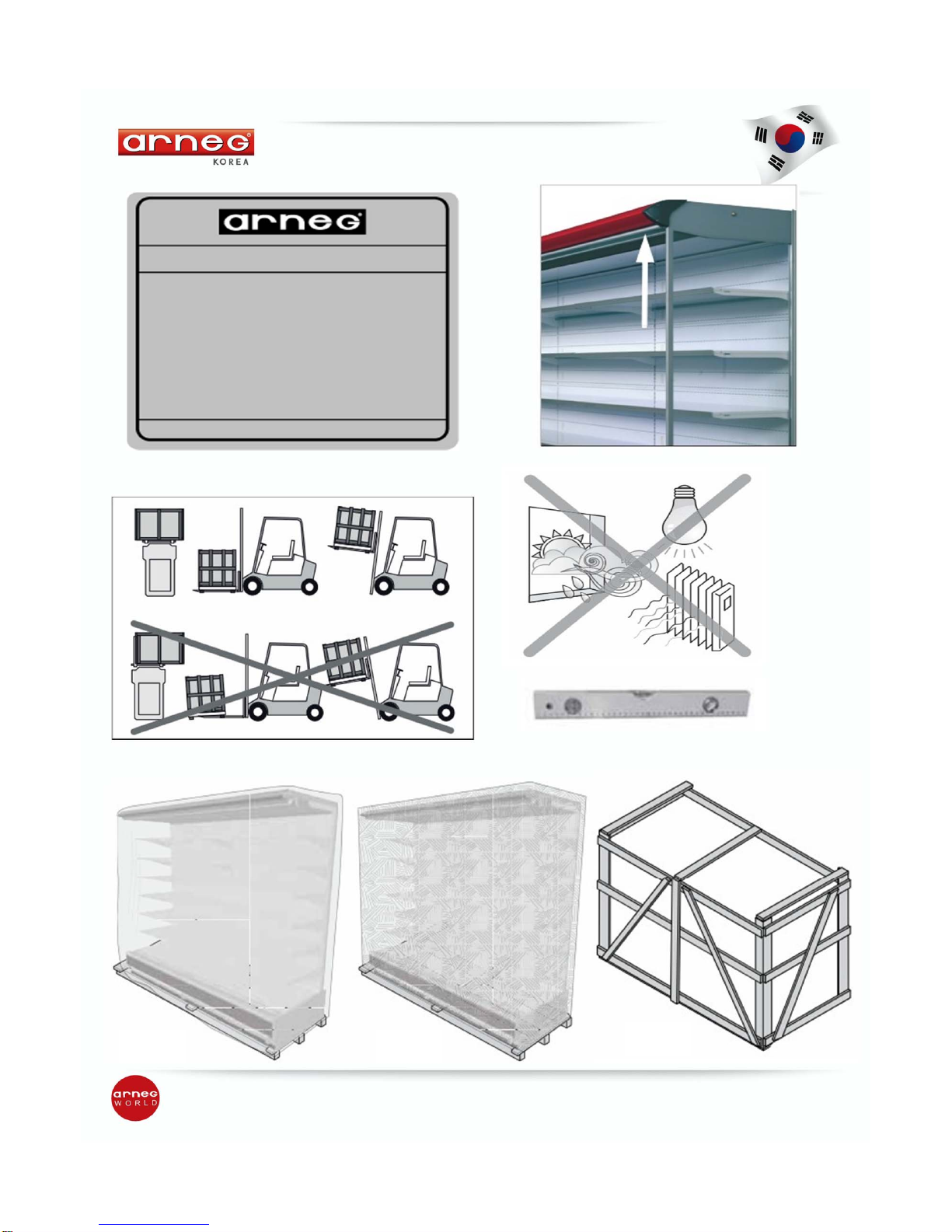

1 - Informational icons.......................................................................................................... 27

2 - Prohibitions and provisions............................................................................................. 27

3 - Purpose of the manual/Field of application - Subjects concerned.................................. 28

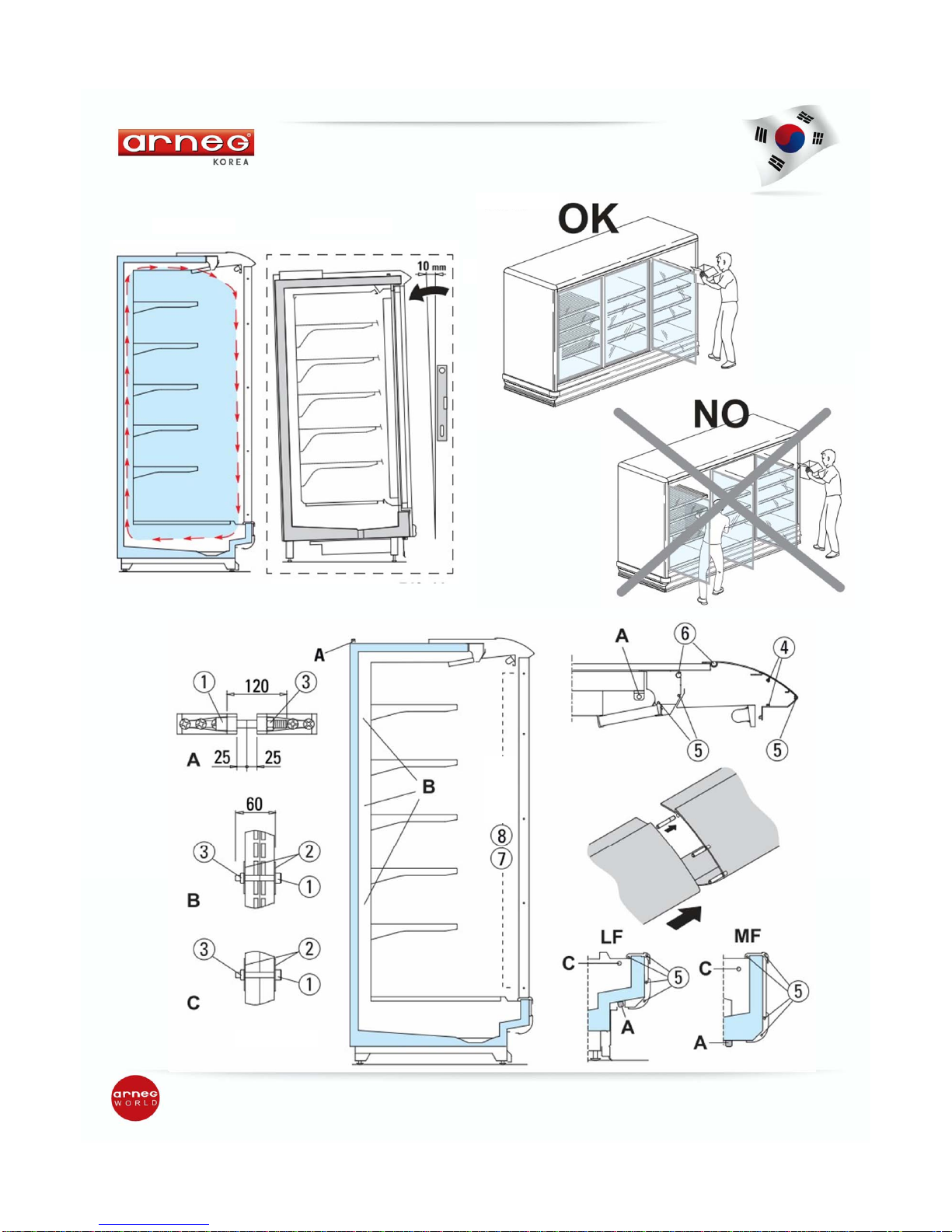

4 - Presentation - Intended use (Pag. 1).............................................................................. 29

5 - Norms and certifications ................................................................................................. 30

6 - Identification - Rating Plate (Rif. 1)................................................................................. 30

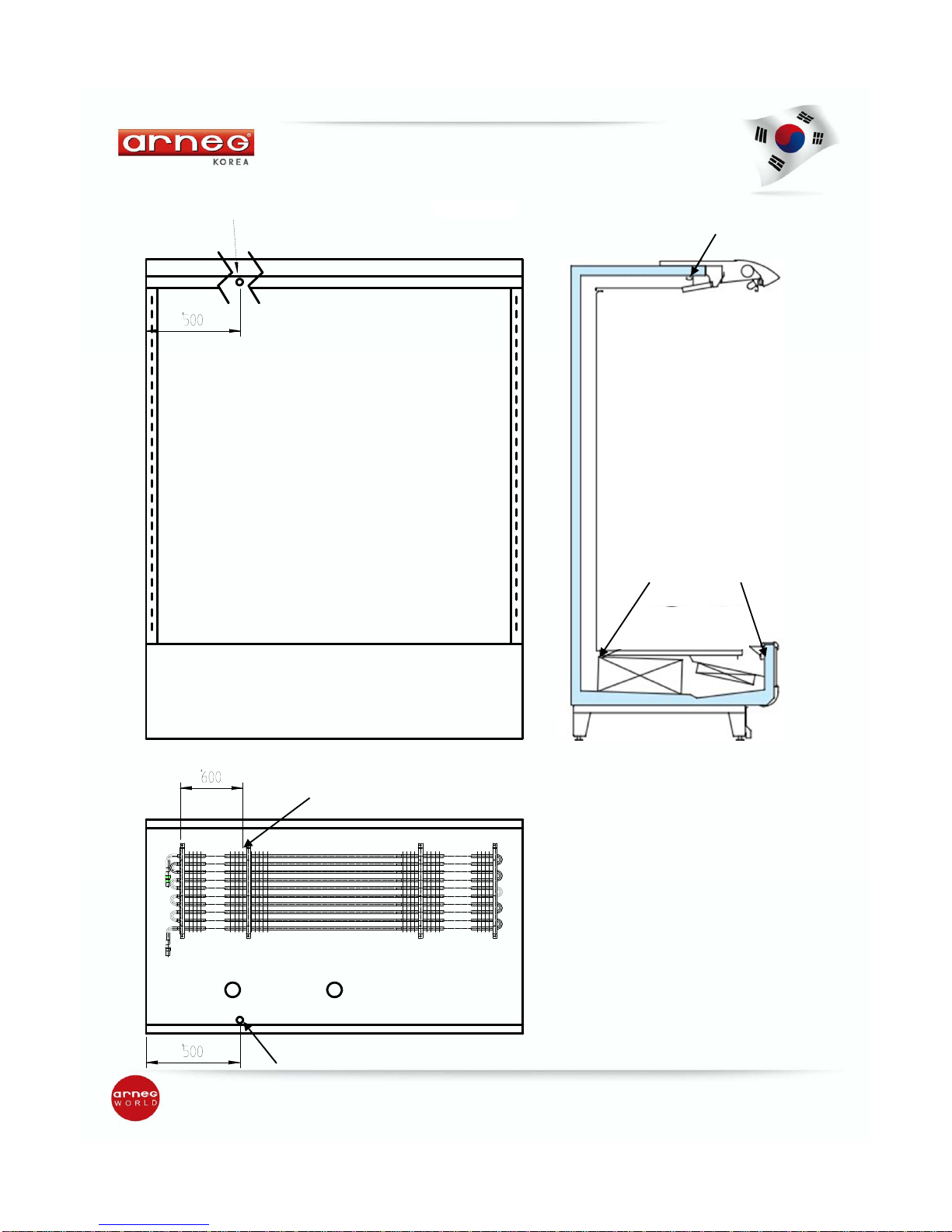

7 - Transport (Rif. 2) - specialized technician - .................................................................... 31

8 - Storage ........................................................................................................................... 31

9 - Receiving, unpacking, first cleaning - qualified operator - .............................................. 31

10 - Installation and environmental conditions - specialized technician - ............................ 32

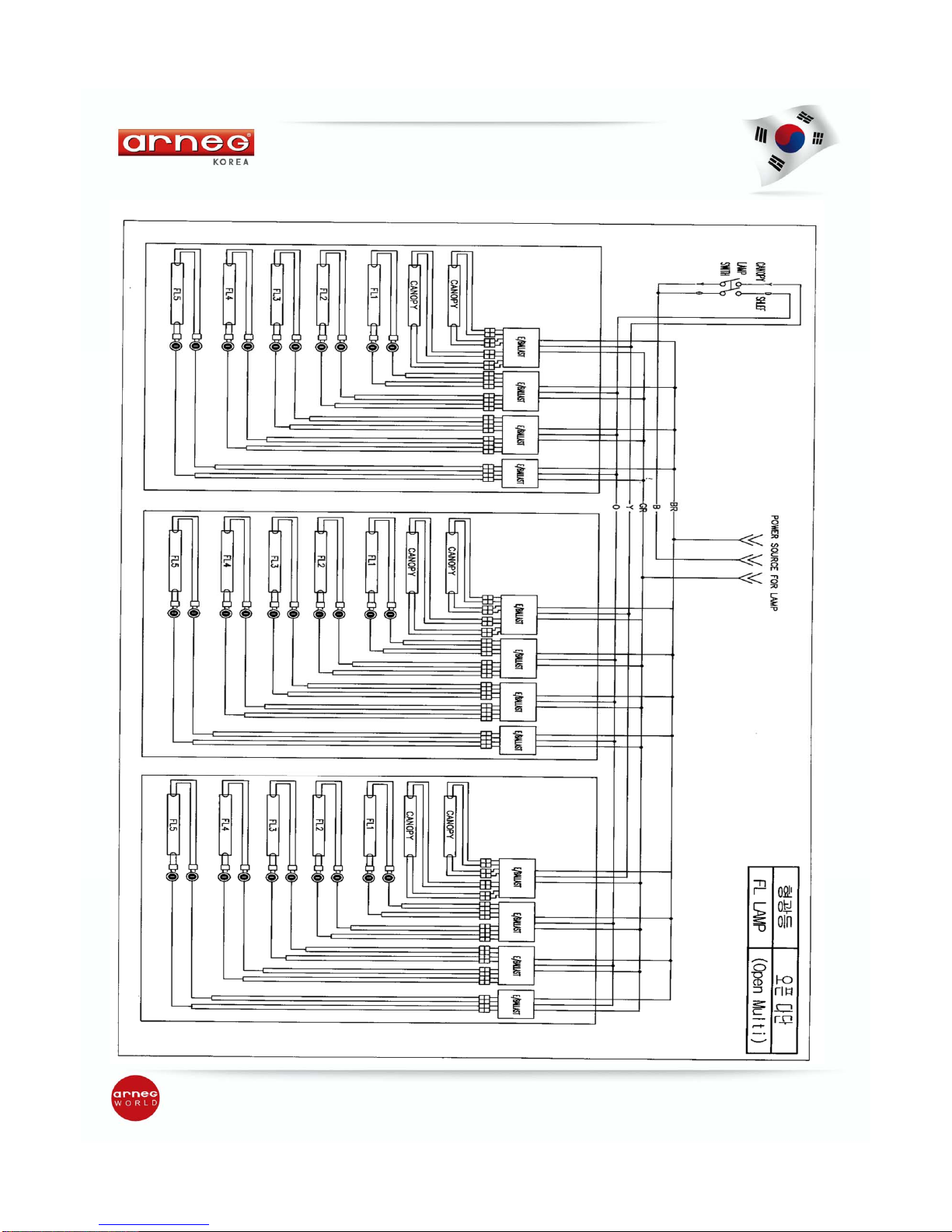

11 - Combining cabinets (Rif. 27) ........................................................................................ 32

12 - Electrical connection (Pag. 8) - specialized technician -............................................... 33

13 - Position of the probes (Rif. 24) - specialized technician -............................................. 34

14 - Start, control, and adjustment of the temperature - specialized technician -................ 34

15 - Loading the cabinet - qualified operator - ..................................................................... 34

16 - Defrosting and water drainage (Rif. 22)........................................................................ 35

16_1 - Water drainage:.................................................................................................... 35

17 - Lighting ......................................................................................................................... 35

18 - Replacing the lamps (Rif. 20) ....................................................................................... 35

19 - Glass-paneled closures ................................................................................................ 36

20 - Anti-condensation and demisting.................................................................................. 36

21 - Maintenance and cleaning - qualified operator -........................................................... 36

21_1 - Cleaning of the outer parts (Daily / Weekly)......................................................... 37

21_2 - Cleaning the internal parts (Monthly) ................................................................... 37

21_3 - Cleaning the honeycomb structure (Rif. 6)........................................................... 37

21_4 - Cleaning the parts in stainless steel..................................................................... 37

21_5 - Inspection of the parts.......................................................................................... 38

22 - Dismantling the cabinet - specialized technician - ........................................................ 38