ARP Control v5x General Installation Guide 20 ©2013 - 2020 ARPC L.L.C. All rights reserved. 8

04/20/20

ARP Installation Search Engine

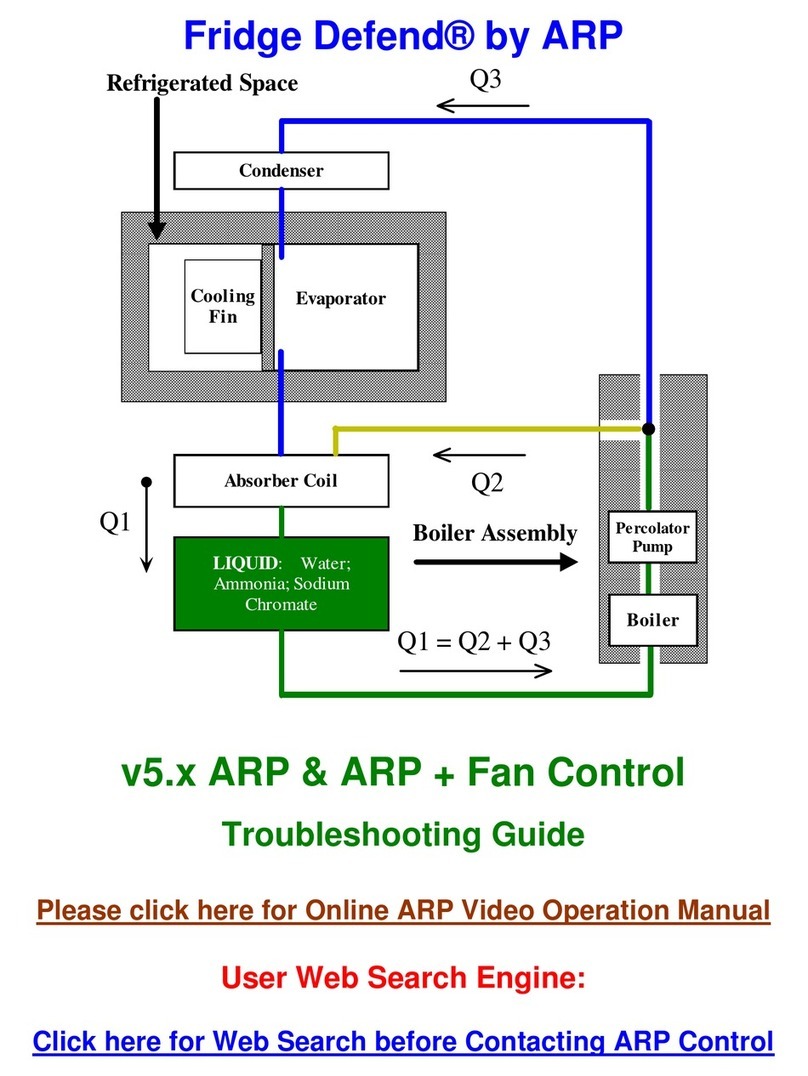

3. Push the insulation aside so you can

identify the various tubes. Sections of

insulation may also be removed to gain

access to the tubing inside.

4. Be sure to mount the sensor to the boiler

tube. This tube is most easily identified by the

fact that the electrical heater holders are

welded directly to the boiler tube. It is up to

the installer to confirm the correct tube. As a

rule of thumb, but not always, Dometic

cooling units generally have the boiler tube

behind the flue tube and Norcold boiler tubes

are in front of the flue tube as seen looking

into the cooling unit compartment door. In the

following drawings the flue tube is red for

identification.

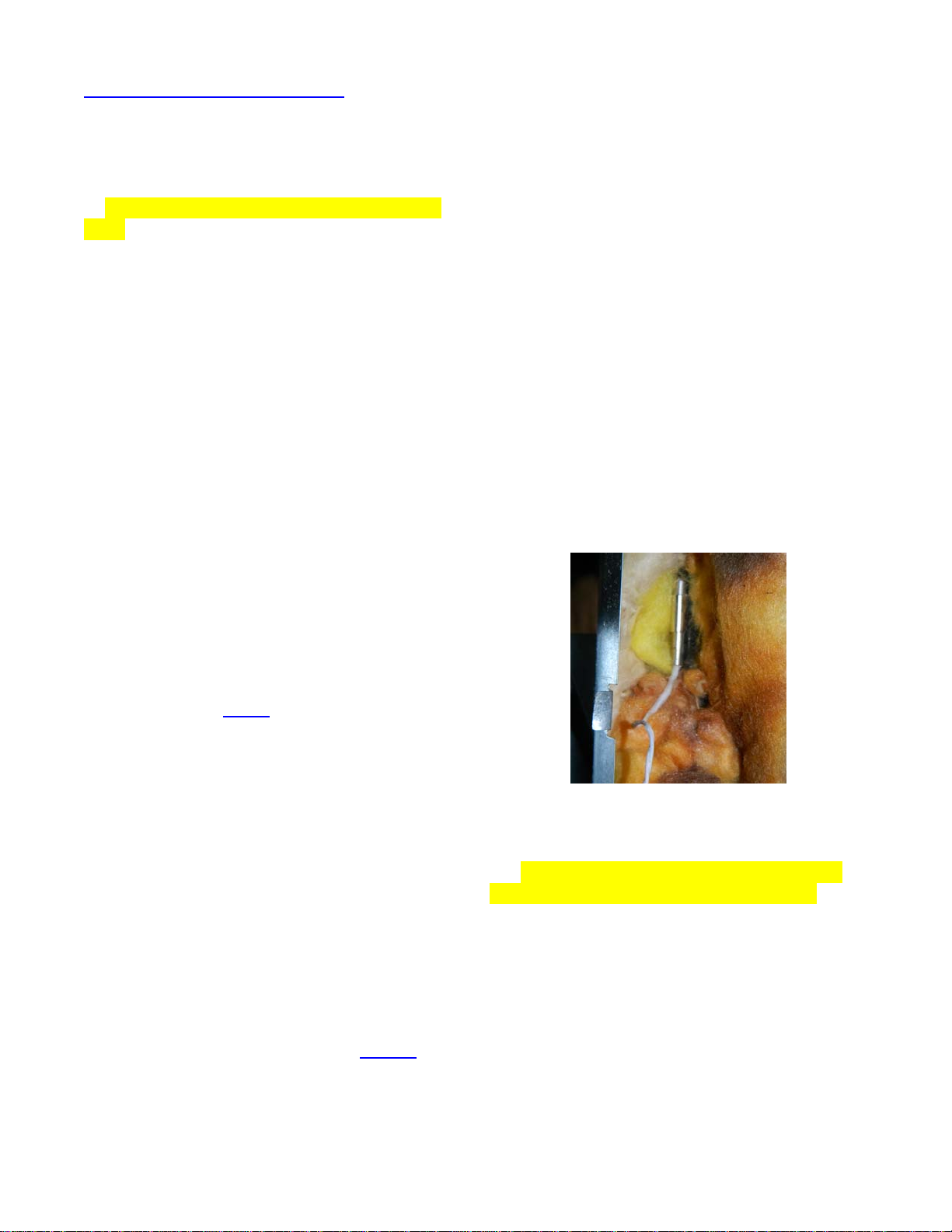

5. Referencing Figures 3 thru 4, the RTD and

clip are shown, where the RTD has been

super glued to the clip for ease of installation.

Note that the alignment of the clip depends

on the boiler tube arrangement for the

particular boiler assembly, see RTD and clip

next to boiler assembly in Figures 3 thru 4.

Also note that the wires exiting the RTD

housing are aligned away from the center of

the clip so that insulation can be placed

between the boiler process tube and the RTD

wires as seen in Fig. 2.

If the clip is glued in the wrong position, use

Acetone to release the supper glue. Do not

get Acetone on the wire end of the RTD.

6. Determine the position of the RTD so that

it meets the following criteria:

•The sensor tip is touching the boiler

process tube.

•The sensor is mounted away from the flue

tube.

•The sensor is a least 1” above the electric

heating elements, anywhere in the range

of 1" to 3" above heating elements.

The maximum sensor height is below the 2

nd

from top absorber coil as seen in Fig. 3a.

Fig. 3a and b show typical Dometic left and

right-hand boiler installation of the ARP RTD.

The red tube seen in these figures is the gas

flue tube, make sure the RTD is not in

contact with this tube, and the RTD is very

well insulated from this heat source.

7. Once the position of the RTD has been

determined, rub silicone grease on the clip

and the boiler tube to aid with step 8 below.

Snap the RTD around the boiler process tube

very near the location you determined in step

6.

8. Position the RTD to meet the criteria in

step 6 above by sliding the RTD from side to

side or up and down.

9. Repack the insulation into the boiler. Pack

extra insulation around the sensor and

between the sensor and any heat sources

such as the flue tube and the electric heaters.

Referencing Fig. 2, pack insulation between

the flue and the sensor, and under the sensor

wire. This will help prevent the heat from flue

tube and electric heaters from affecting the

RTD measurement and insure an accurate

measurement of the boiler tube.

Fig. 2 –Insulate around RTD and Between

Wire and Boiler Tube; Be Sure to Insulate

between Flue Tube and Sensor.

10. Sharp objects, such as the sheet metal

boiler housing can cut the sensor wires. The

result is the ARP will detect an open or short

of the sensor and report an error. Where

applicable, to eliminate this issue, wrap

insulation around the sensor wire where it

exits the sheet metal boiler housing and use

wire ties to secure the wiring so that vibration

cannot cause wiring issues.

4.2 Dometic Temperature Sensor

Dometic has two types of boilers as seen in

Fig 3a and 3b, the right-hand boiler and the

left-hand boiler. Please note the different