ARP Control v5.x Troubleshooting Guide 0©2013-2020 ARPC L.L.C. All rights reserved.

104/20/202

SAFETY

1.1 Acronyms and Abbreviations

ARP: ARP Control = Fridge Defend

RTD: ARP Control temperature sensor;

Resistance Temperature Detector is the type

of sensor used.

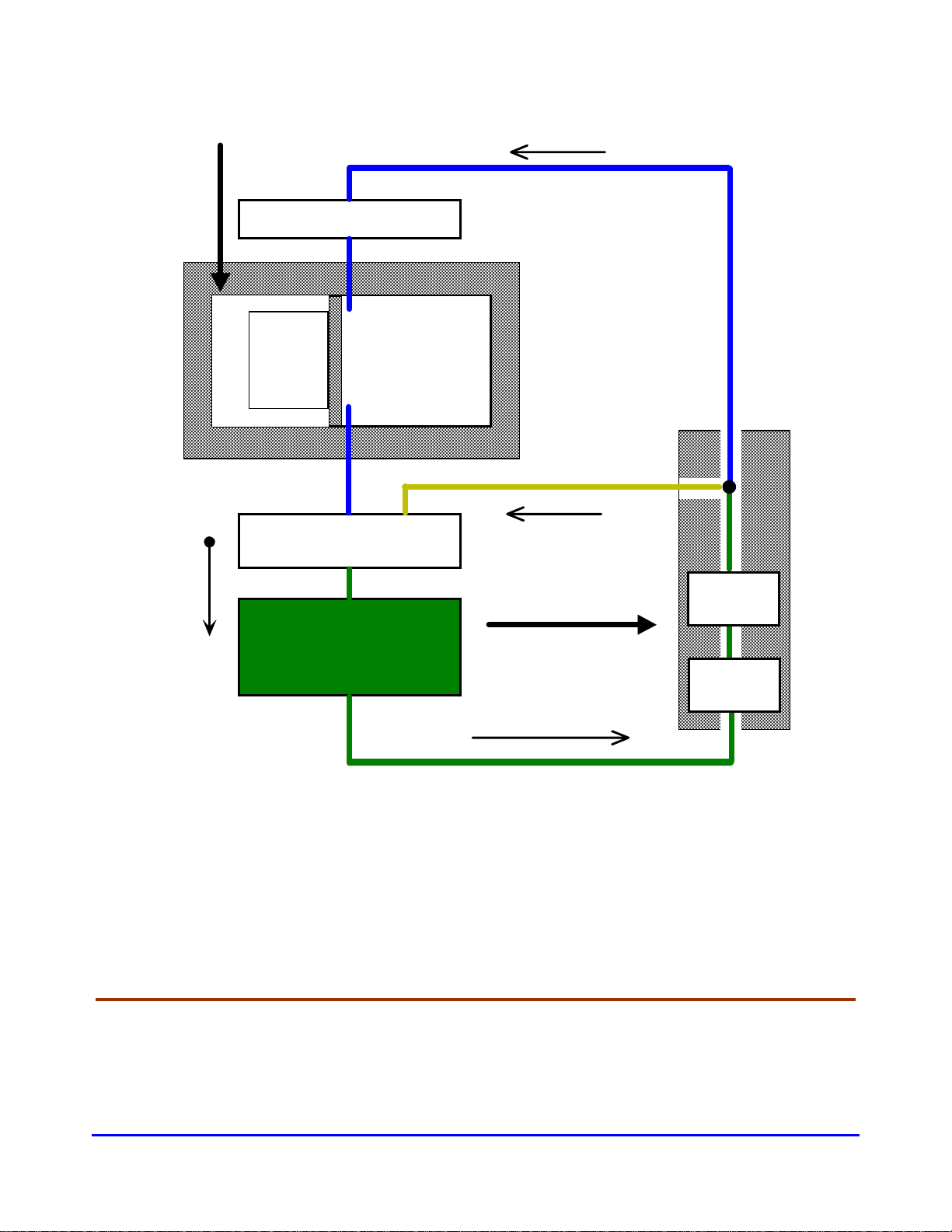

Q: Flow of fluid either as a gas or liquid.

SPAR: Single Pressure Absorption

Refrigerator.

1.2 Hazard Information

Hazard information includes terms, symbols

and instructions used in this manual or on

the equipment to alert operating and service

personnel to the recommended precautions

in the care, use and handling of the ARP

Control.

1.3 Terms & Warnings Symbols

1.4 Work Safely

There are many ways to install the ARP

Control. Make safety your first priority!

The installer’s knowledge, skill, and ability

are important for safely installing the system

and maintaining or troubleshooting it. If you

are unsure of your ability to use the ARP as

a diagnostic tool, have a qualified individual

do the work.

1.5 Operation Safety

The ARP Control and 'ARPrvSafe' infer that

the use and operation of this control can add

a level of safety to your absorption

refrigeration system in your RV. No other RV

absorption refrigerator control monitors the

boiler temperature, and turns off the heat

source to the refrigerator before damage can

be done to the internal fluids in the

refrigerator cooling unit. The ARP cannot

prevent RV refrigerator failure if the

manufacture built the cooling unit in a

manner that would result in premature failure.

In addition, if damage to the cooling unit has

occurred before the ARP was installed; the

ARP cannot remedy this damage

__________________________________________________________________________________________

SETUP MODE

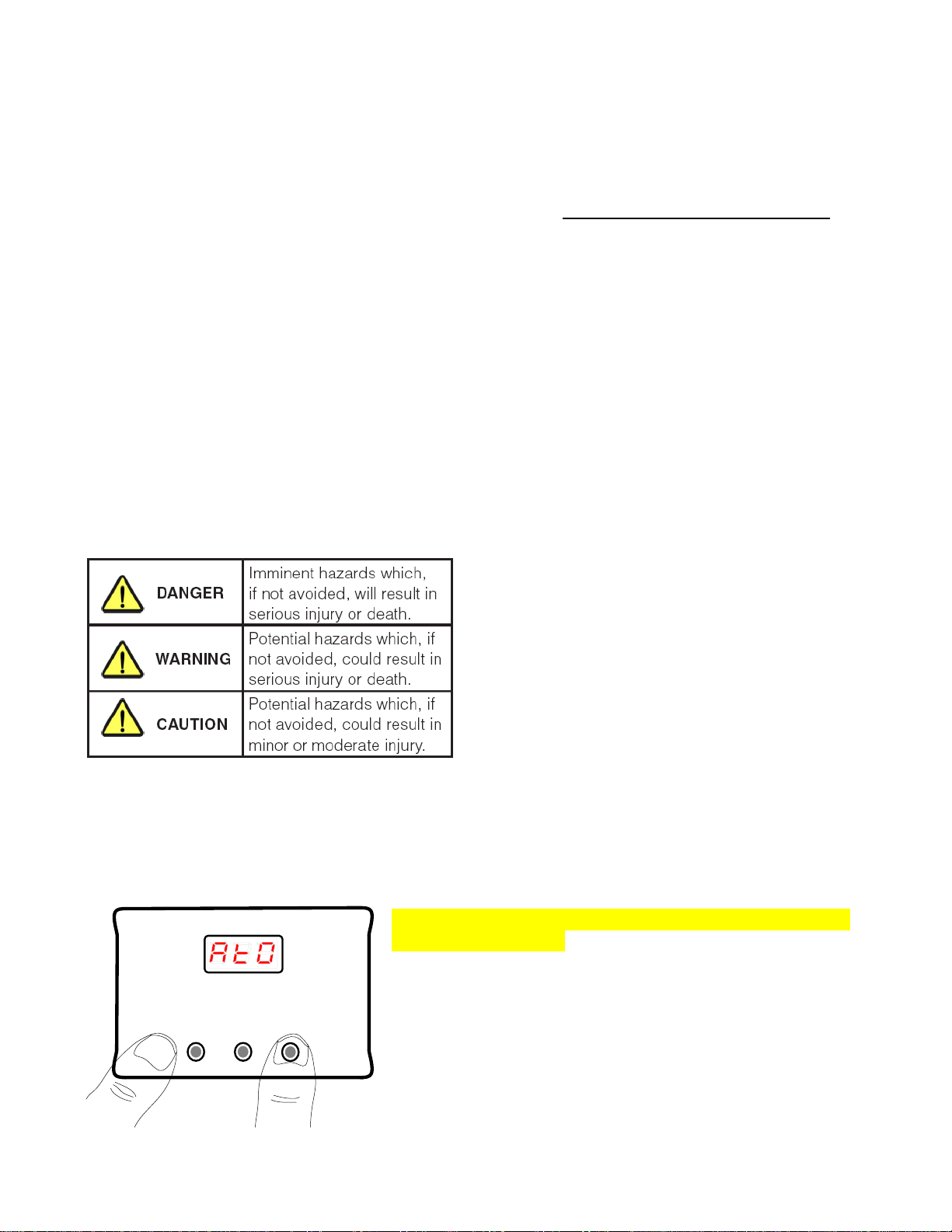

2.1 Activate SetUp Mode

On/Off Display SetUp

To place the control into SetUp mode, begin by turning

off the ARP Control (Please see User Guide →Turn off

ARP Control). When the control is off, the SetUp mode is

activated by holding*the right SetUp button and then

momentarily*pressing the On/Off button. When AtO is

displayed, release the SetUp button.

*Please see User Guide section BUTTON FUNCTION

& Ancillary Graphical User Instructions section Turn

ON Control in SetUp Mode .