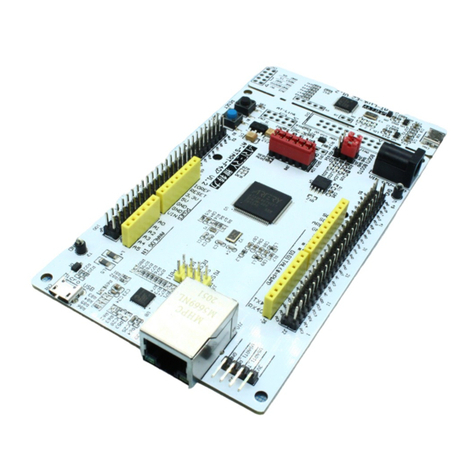

Low Voltage Motor Control Development Board

2022.12.01 2 Ver 2.0.2

Contents

1Board description............................................................................................6

2Software and hardware requirements .............................................................7

3Getting started ................................................................................................8

4Hardware configuration...................................................................................9

4.1 System architecture ..........................................................................................................9

4.2 Jumper and connector location......................................................................................10

4.3 Jumper settings...............................................................................................................11

4.4 Connectors.......................................................................................................................11

4.4.1 CN1 .......................................................................................................................11

4.4.2 CN2 .......................................................................................................................12

4.4.3 CN3 .......................................................................................................................12

4.4.4 CN4 .......................................................................................................................12

4.4.5 CN5 .......................................................................................................................13

4.4.6 CN6 .......................................................................................................................13

4.4.7 Pin header connectors...........................................................................................13

4.5 Test points........................................................................................................................14

5Hardware circuit ............................................................................................16

5.1 Incremental encoder circuit ............................................................................................17

5.2 Hall sensor circuit............................................................................................................17

5.3 Current sensing circuit....................................................................................................18

5.3.1 Phase current sensing circuit.................................................................................18

5.3.2 DC bus current sensing circuit...............................................................................18

5.4 OCP sensing circuit.........................................................................................................19

5.4.1 Three-phase OCP sensing circuit...........................................................................19

5.4.2 Bus OCP sensing circuit........................................................................................19

5.5 Bus voltage sensing circuit.............................................................................................20

5.6 Three-phase output voltage sensing circuit..................................................................20

5.7 Power stage circuit..........................................................................................................22