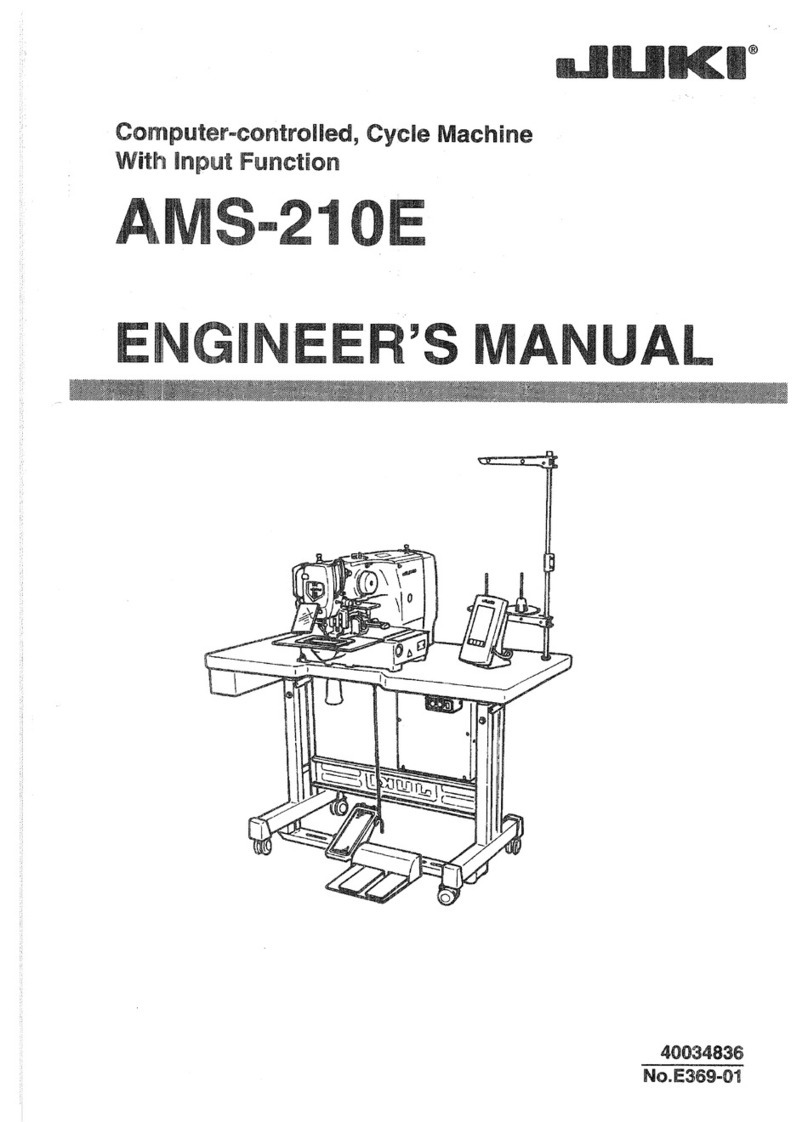

CONTENTS

1. Specifications ......................................................................................................... 1

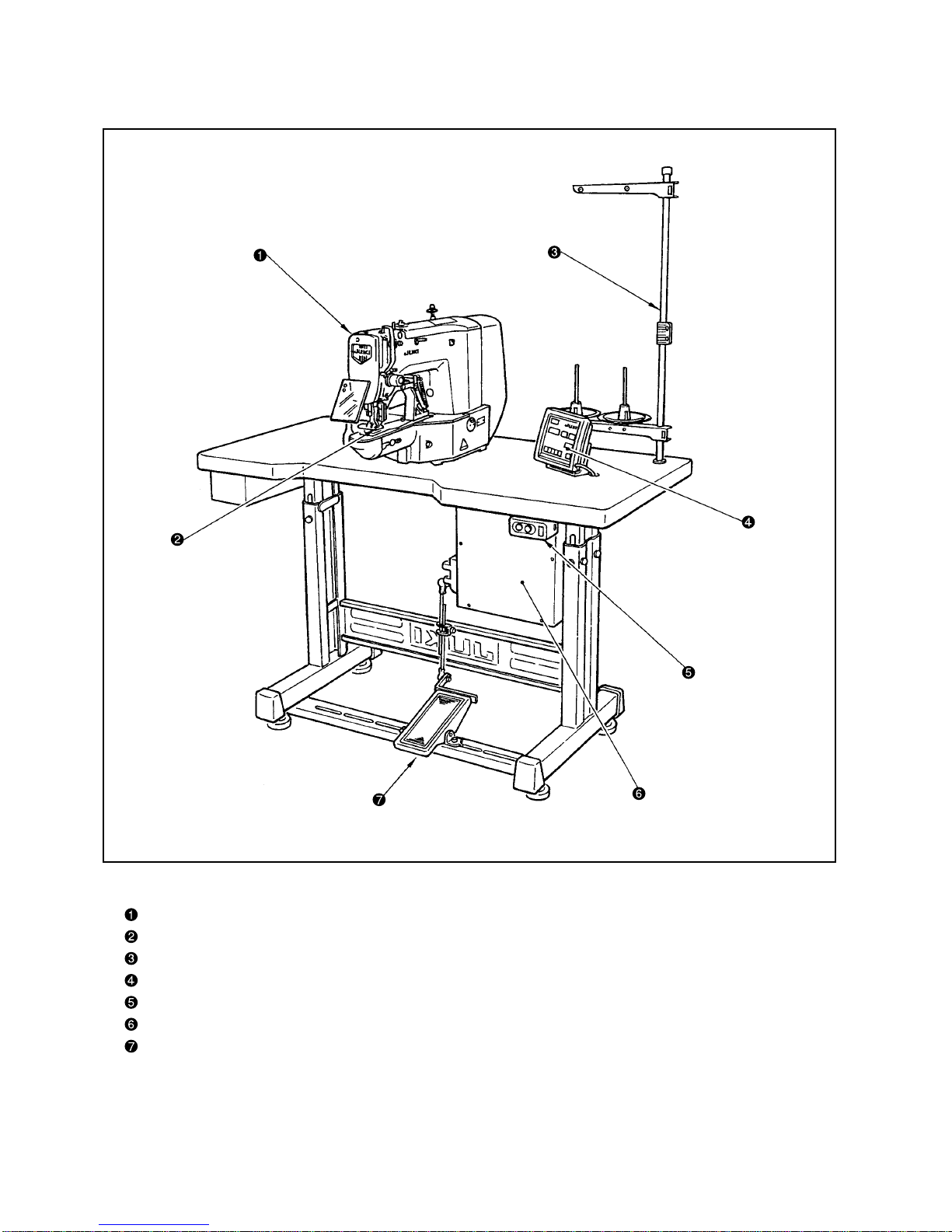

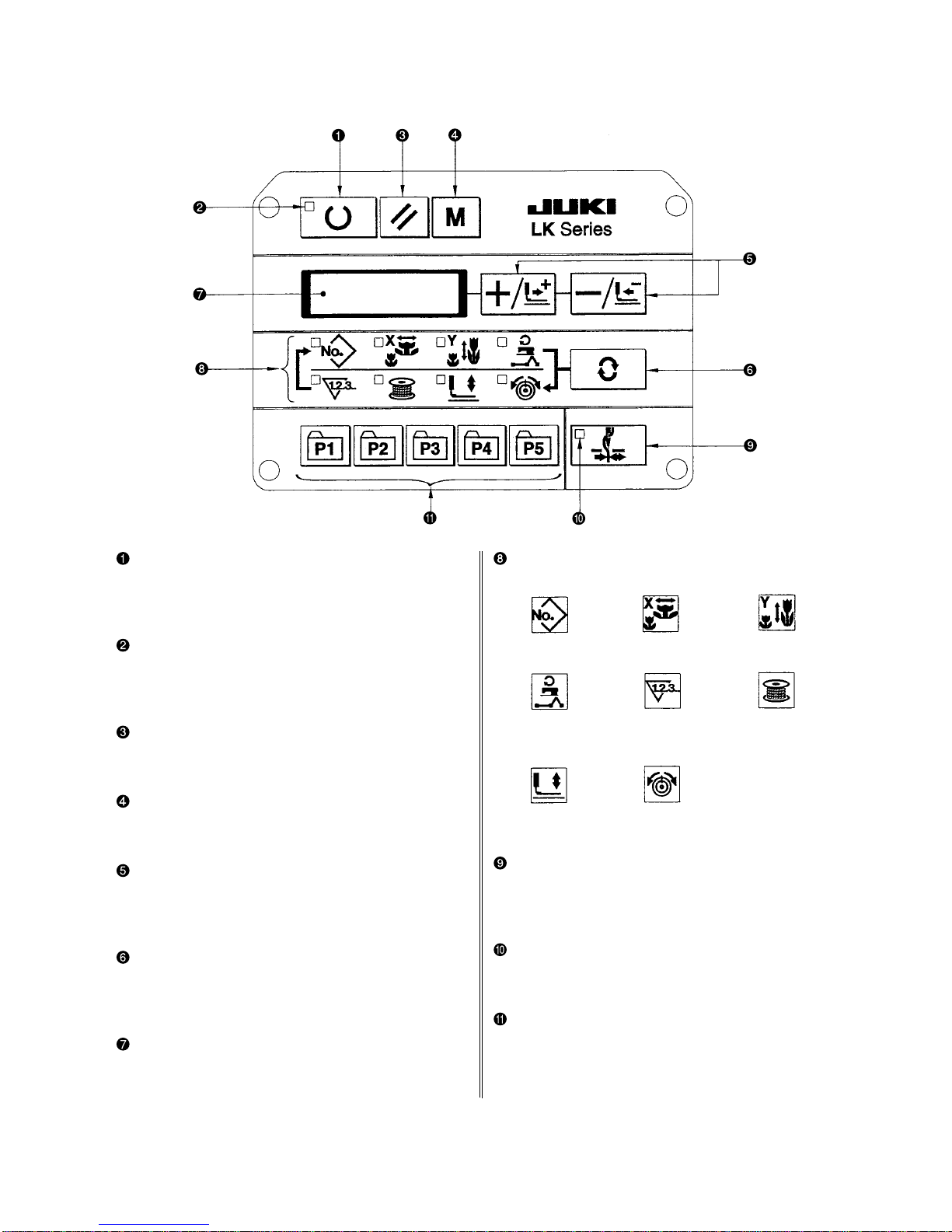

2. Configuration........................................................................................................... 2

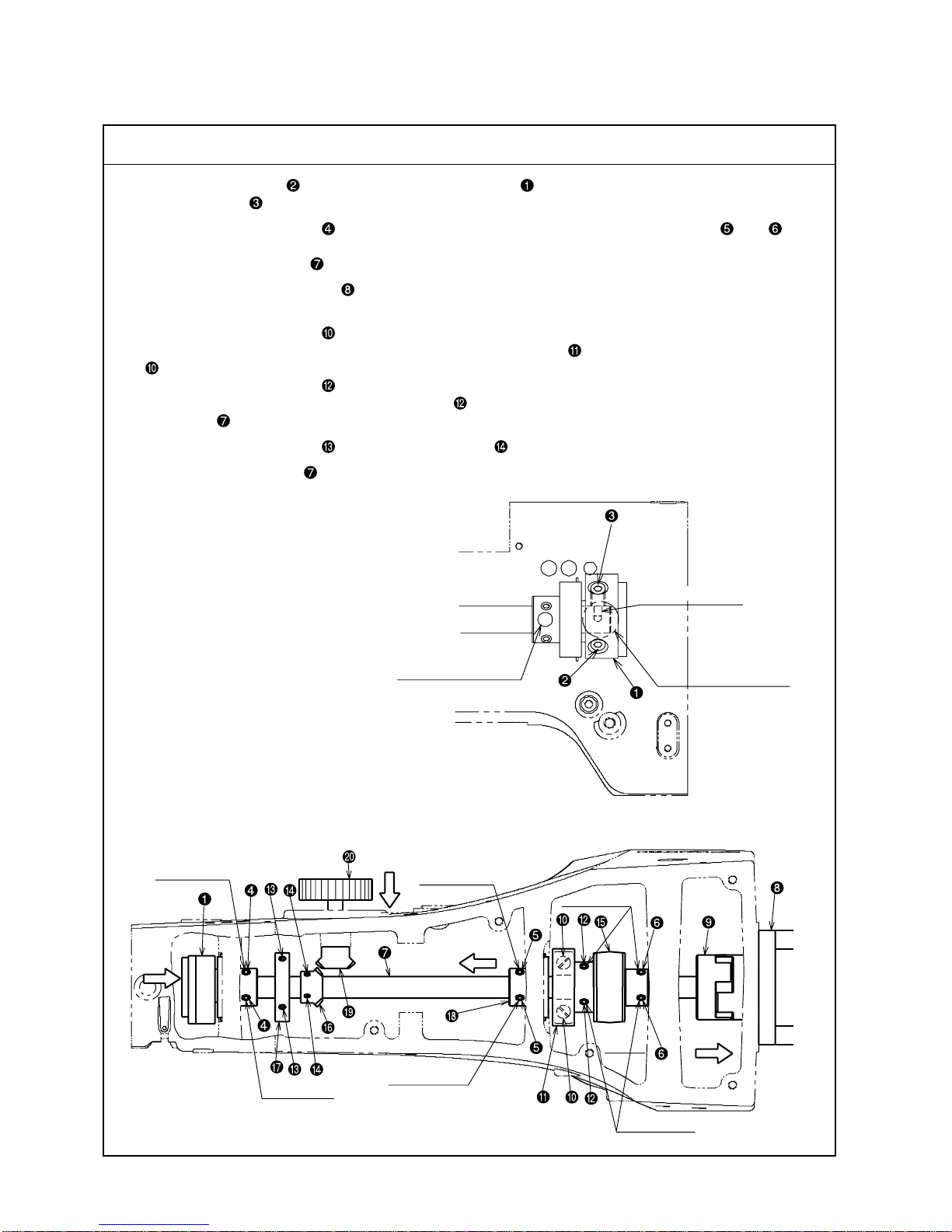

(1) Names of main unit ................................................................................................................... 2

(2) Names and explanation of switches on the operation panel................................................ 3

3. Standard adjustment ..............................................................................................4

(1) Main shaft connection/disconnection..................................................................................... 4

(2) Removal of the main shaft motor and coupling..................................................................... 6

(3) Crank connecting rod connection / disconnection ............................................................... 8

(4) Crank balancer positioning.................................................................................................... 10

(5) Lower shaft backlash adjustment and connection/disconnection .................................... 10

(6) Oscillator gear positioning..................................................................................................... 12

(7) Adjustment of hook oil amount ............................................................................................. 12

(8) Large hook connection / disconnection and oil wick piping .............................................. 14

(9) Adjusting the height of the needle bar.................................................................................. 14

(10) Hook adjustment ................................................................................................................... 16

(11) Thread trimmer cam position adjustment and connection / disconnection ................... 18

(12) Thread trimmer and presser foot origin sensor adjustment............................................. 18

(13) Adjusting the lift of the work clamp foot ............................................................................ 20

(14) Adjusting the thread trimmer sensor .................................................................................. 20

(15) Adjustment of the moving knife and counter knife position ............................................ 22

(16) Adjusting the height of the moving knife and counter knife ............................................ 22

(17) Inclination of the blade point of the counter knife............................................................. 24

(18) Floating amount of the thread tension disk ....................................................................... 24

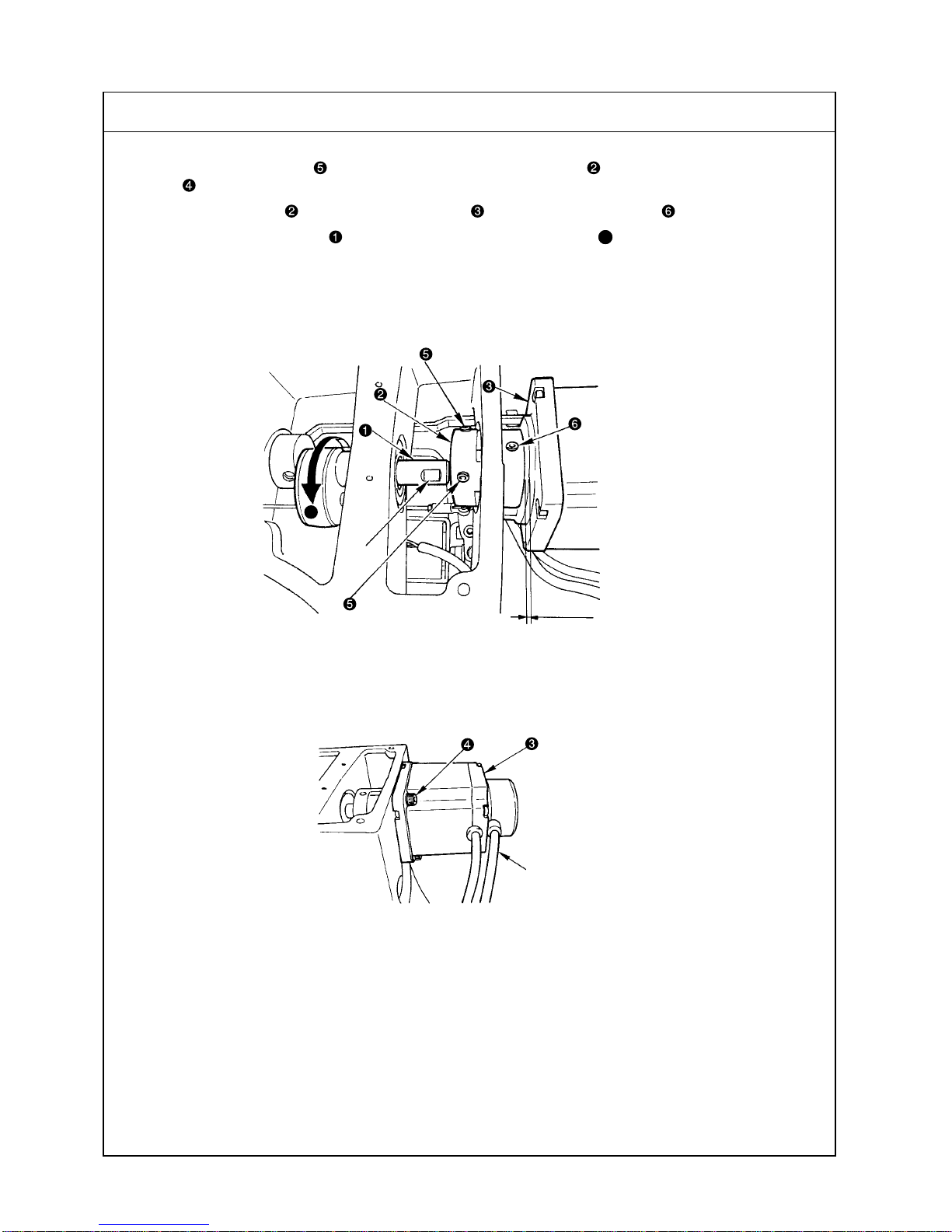

(19) Second thread tension connection / disconnection.......................................................... 26

(20) AT unit connection / disconnection .................................................................................... 28

(21) Position of the mechanical origin........................................................................................ 30

(22) Adjusting the Y origin sensor ..............................................................................................30

(23) Adjusting the X origin sensor ..............................................................................................32

(24) Adjusting the wiper position................................................................................................ 32

(25) Adjusting the wiper spring (LK-1903A only) ...................................................................... 34

(26) Adjusting the position of the X feed motor and the Y feed motor

(Adjusting the backlash of the driving gear)..................................................................... 34

(27) Installing the feed plate support plate ................................................................................ 36

(28) Installation of the feeder bar rear cover.............................................................................. 36

(29) Adjustment of the bobbin winder driving wheel position ................................................. 38

(30) Adjusting the bobbin winder amount.................................................................................. 38

(31) Adjustment of the hook upper spring position .................................................................. 40

(32) Shuttle felt.............................................................................................................................. 40

(33) Shape of the shuttle race ring.............................................................................................. 42

(34) Adjustment of the thread take-up spring............................................................................ 42

(35) Needle thread clamp device connection / diconnection ................................................... 44

(36) Adjusting the needle thread clamp sensor......................................................................... 46

(37) Adjusting the needle thread clamp notch........................................................................... 48

4. Sub-class information .......................................................................................... 50

(1) Models classified by button sizes (LK-1903A) ..................................................................... 50

(2) Table of Standard Patterns (LK-1903A)................................................................................. 51