CONTENTS

SPECIFICATIONS ................................................................................................................................1

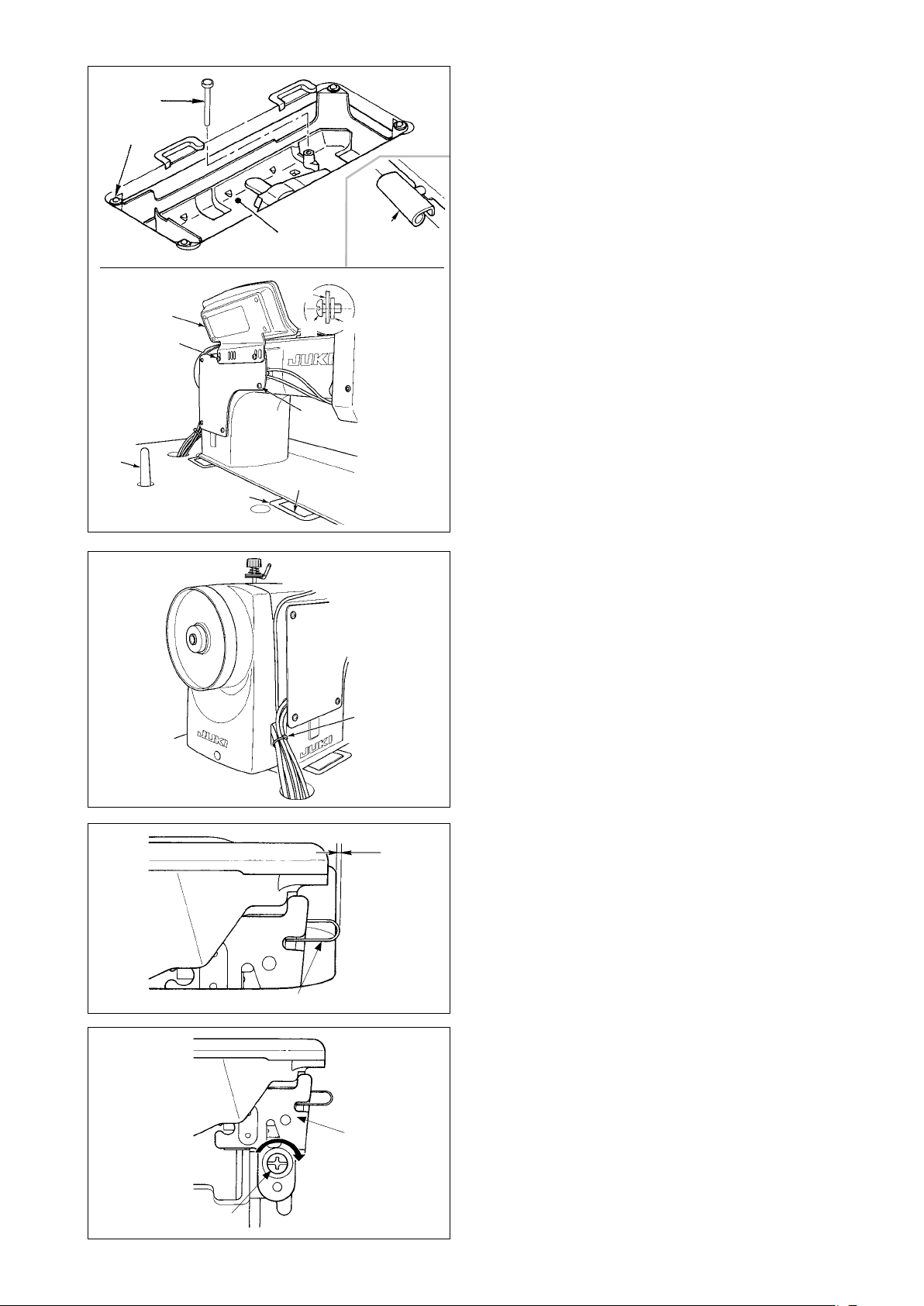

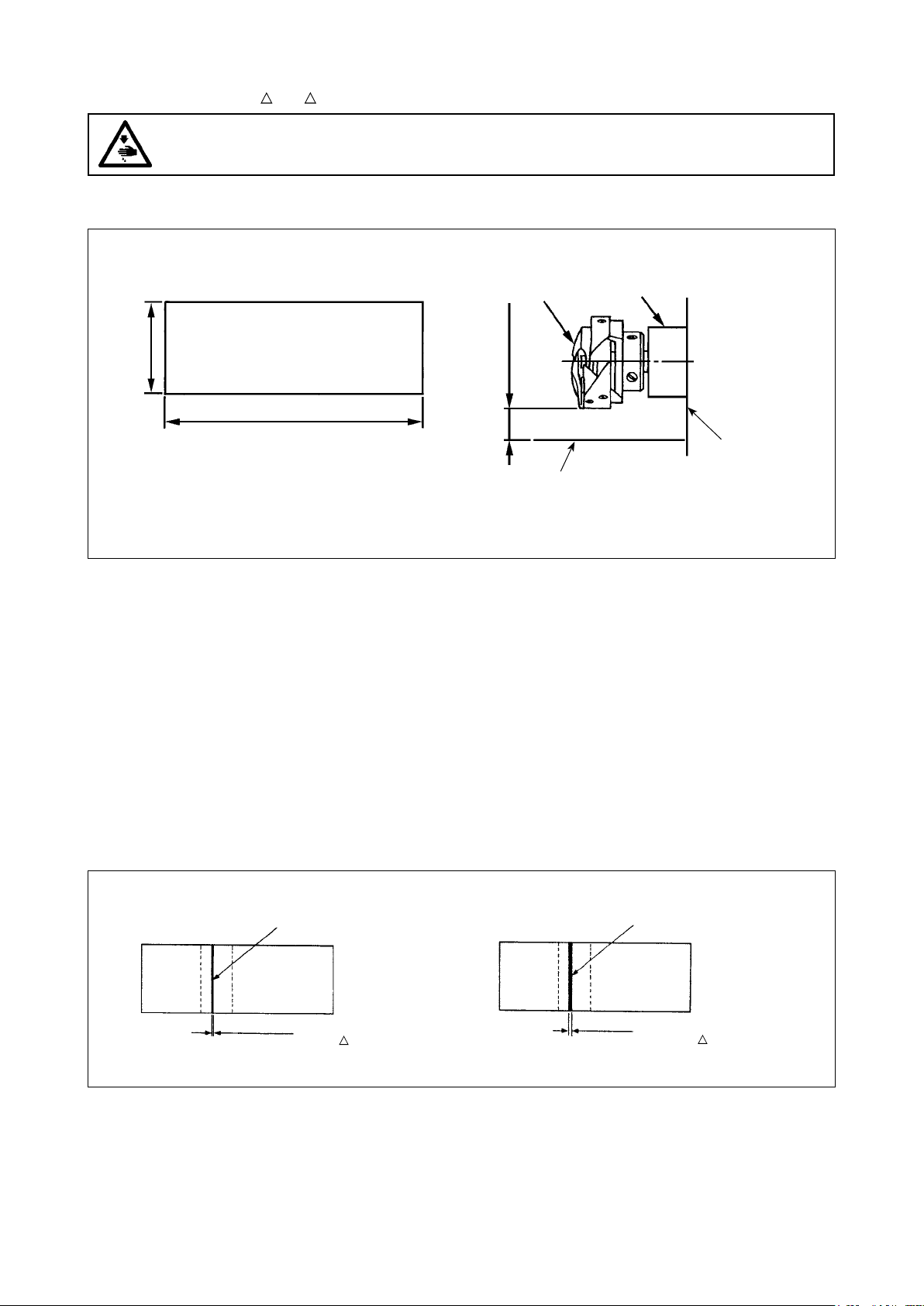

1. INSTALLATION............................................................................................................................2

2. ADJUSTING THE HEIGHT OF THE KNEE LIFTER ....................................................................4

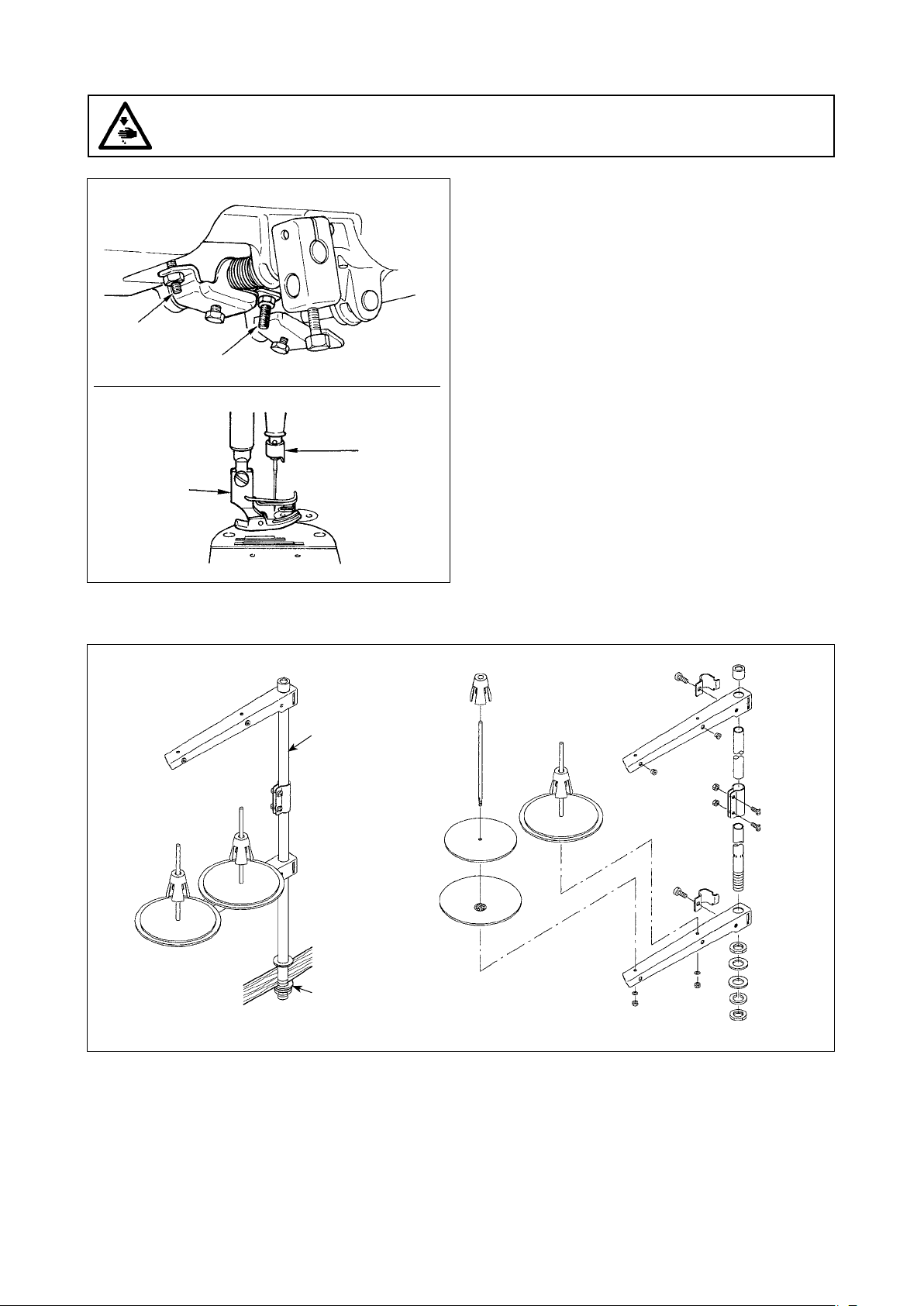

3. INSTALLING THE THREAD STAND............................................................................................4

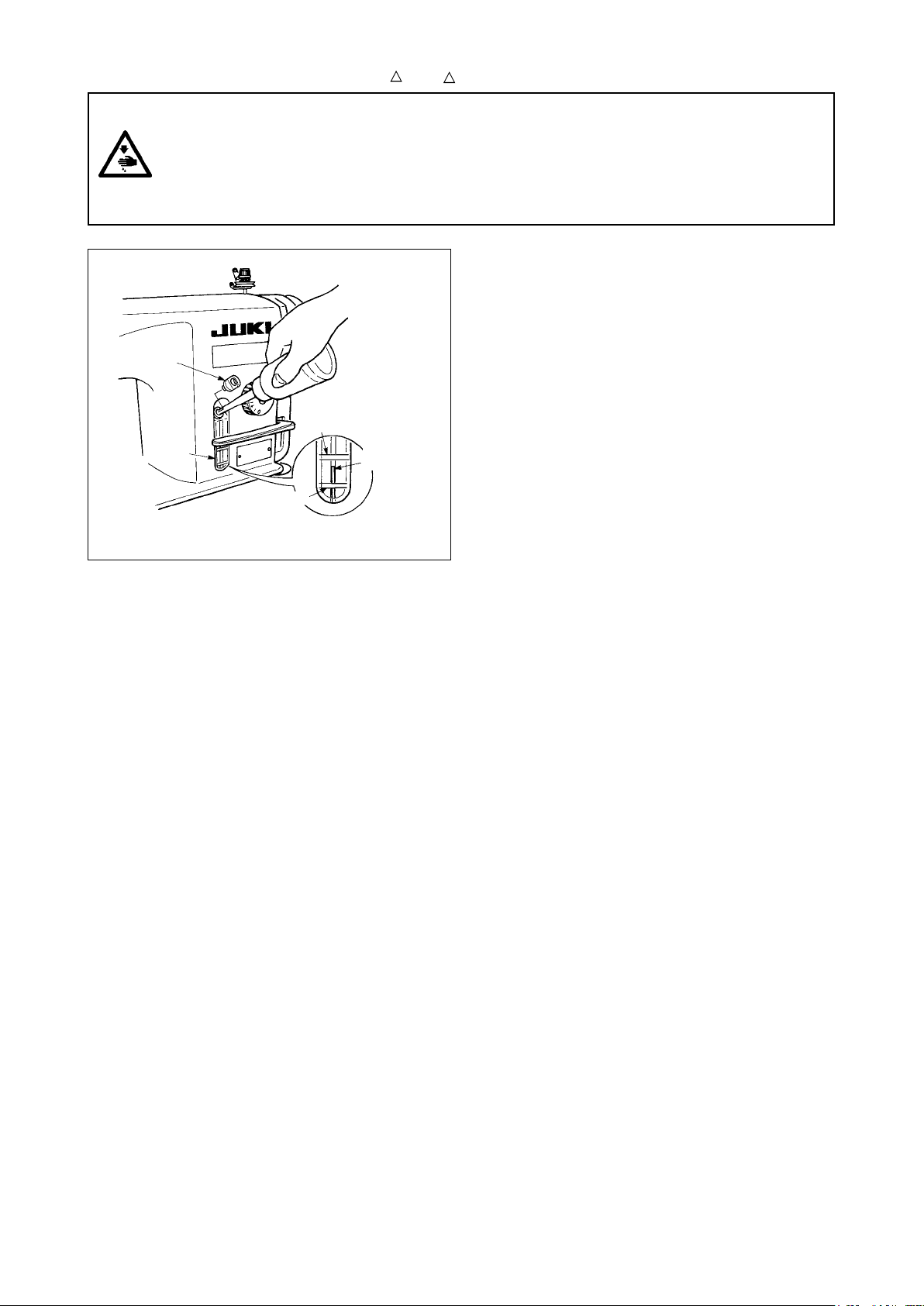

4. LUBRICATION (DDL-9000B-S , -M ).....................................................................................5

5. ATTACHING THE NEEDLE ..........................................................................................................6

6.

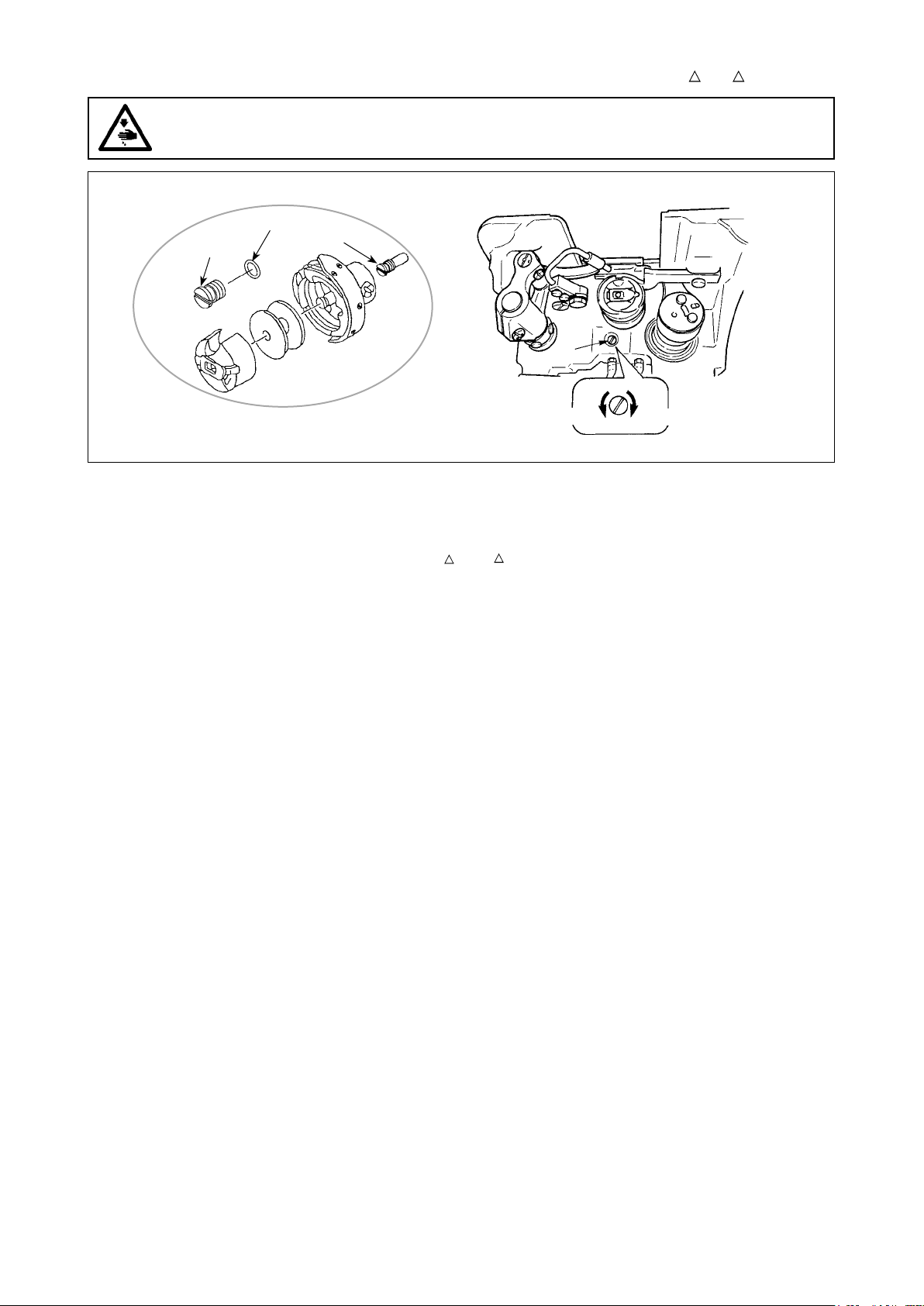

SETTING THE BOBBIN INTO THE BOBBIN CASE .......................................................................... 6

7. ADJUSTING THE AMOUNT OF OIL (OIL SPLASHES) IN THE HOOK(DDL-9000B-S , -M ) .7

(1) How to conrm the amount of oil (oil splashes) ...................................................................................... 7

(2) Sample showing the appropriate amount of oil....................................................................................... 7

8. ADJUSTING THE AMOUNT OF OIL IN THE HOOK (DDL-9000B-S , -M )..............................8

9. THREADING THE MACHINE HEAD............................................................................................9

10. THREAD TENSION.......................................................................................................................9

(1) Adjusting the needle thread tension........................................................................................................ 9

(2) Adjusting the bobbin thread tension ....................................................................................................... 9

11. WINDING THE BOBBIN THREAD .............................................................................................10

12. PRESSER FOOT PRESSURE....................................................................................................11

13.

ADJUSTING THE STITCH LENGTH............................................................................................. 11

14.

ADJUSTING THE THREAD TAKE-UP SPRING AND THE THREAD TAKE-UP STROKE.................. 12

15. ADJUSTING THE NEEDLE STOP POSITION ...........................................................................13

(1) Stop position after thread trimming ....................................................................................................... 13

(2) Adjusting procedure of the needle up/down stop position..................................................................... 13

16. PEDAL PRESSURE AND PEDAL STROKE..............................................................................14

(1) Adjusting the pressure required to depress the front part of the pedal ................................................. 14

(2) Adjusting the pressure required to depress the back part of the pedal ................................................ 14

(3) Adjusting the pedal stroke .................................................................................................................... 14

17. ADJUSTMENT OF THE PEDAL.................................................................................................14

(1) Installing the connecting rod ................................................................................................................. 14

(2) Adjusting the pedal angle...................................................................................................................... 14

18. PEDAL OPERATION ..................................................................................................................15

19. NEEDLE-TO-HOOK RELATIONSHIP ........................................................................................16

20. ONE-TOUCH TYPE REVERSE FEED STITCHING MECHANISM............................................17

21. ADJUSTING THE POSITION OF THE WIPER (DDL-9000B- -WB, -0B) ............................18

22. CUNTER KNIFE..........................................................................................................................19

23. HEIGHT AND TILT OF THE FEED DOG ....................................................................................20

(1) Standard value of the height of the feed dog ........................................................................................ 20

(2) Adjusting the height and tilt of the feed dog .......................................................................................... 20

24. ADJUSTING THE FEED TIMING ...............................................................................................21

25. THREAD TENSION RELEASE RELEASING MECHANISM .....................................................21

26. MICRO-LIFTING MECHANISM OF THE PRESSER FOOT.......................................................22

27. SEWING CONDENSED STITCHES ...........................................................................................23

28. FEED CONVERSION SPRING MECHANISM (DDL-9000B-S , -M )...................................23

29. CARE ..........................................................................................................................................24

(1) Conrmation of the amount of oil in the hook oil tank. .......................................................................... 24

(2) Cleaning ............................................................................................................................................... 24

i