2

Contents

1 Basic information ....................................................................................................................... 3

1.1 Intended use ...................................................................................................................... 3

1.2 Work sites .......................................................................................................................... 3

1.3 For your safety ................................................................................................................... 4

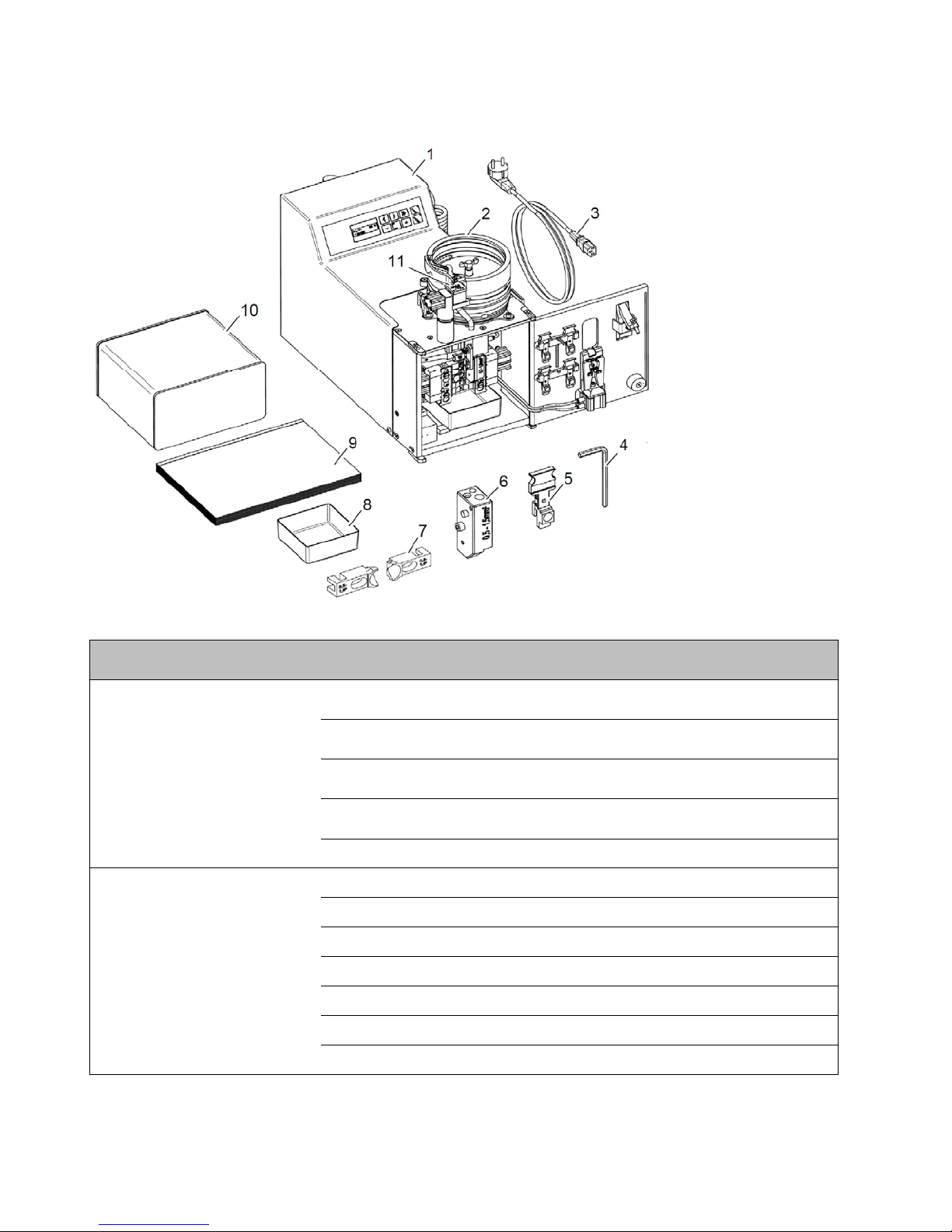

2 Description of the FC-2#0 ........................................................................................................ 5

2.1 Scope of supply ................................................................................................................. 5

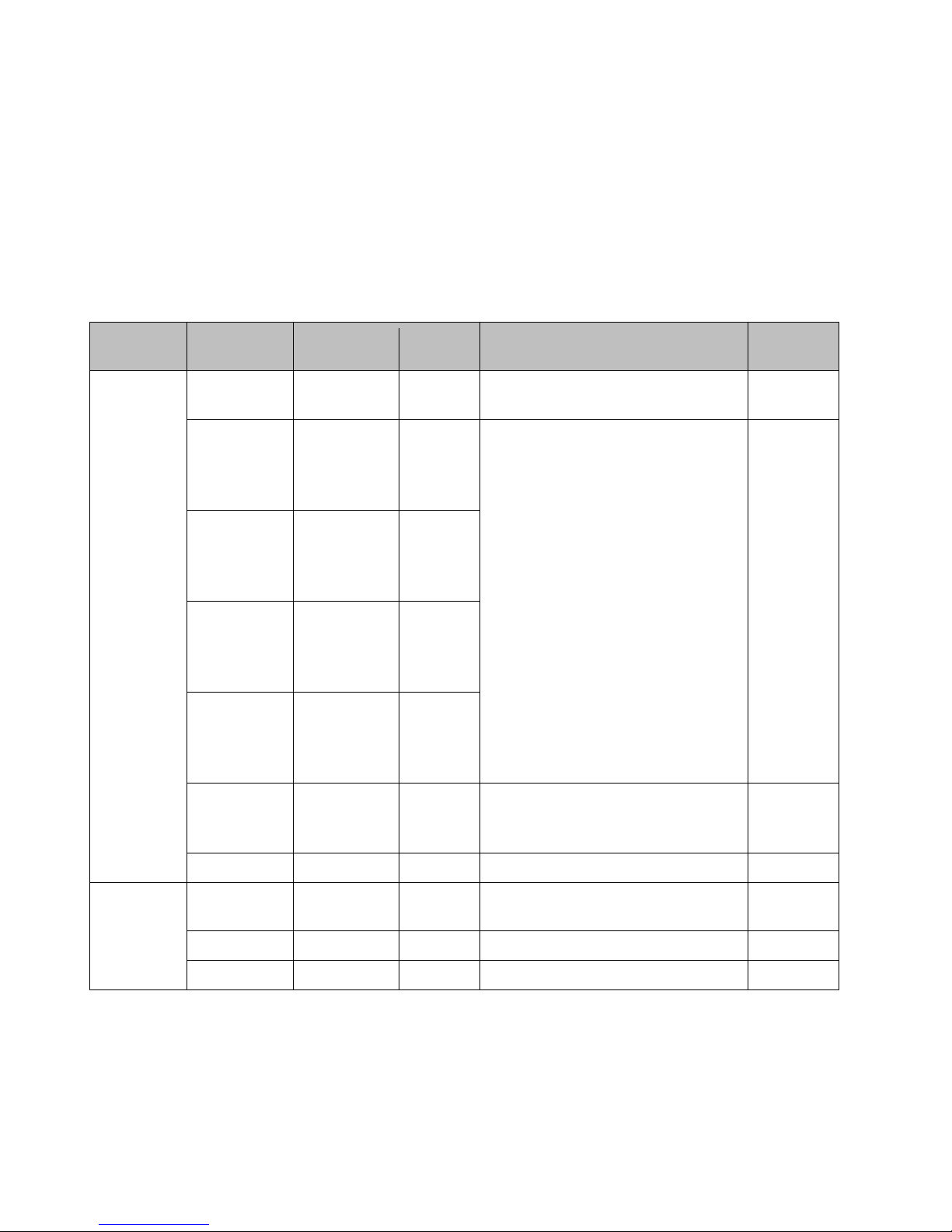

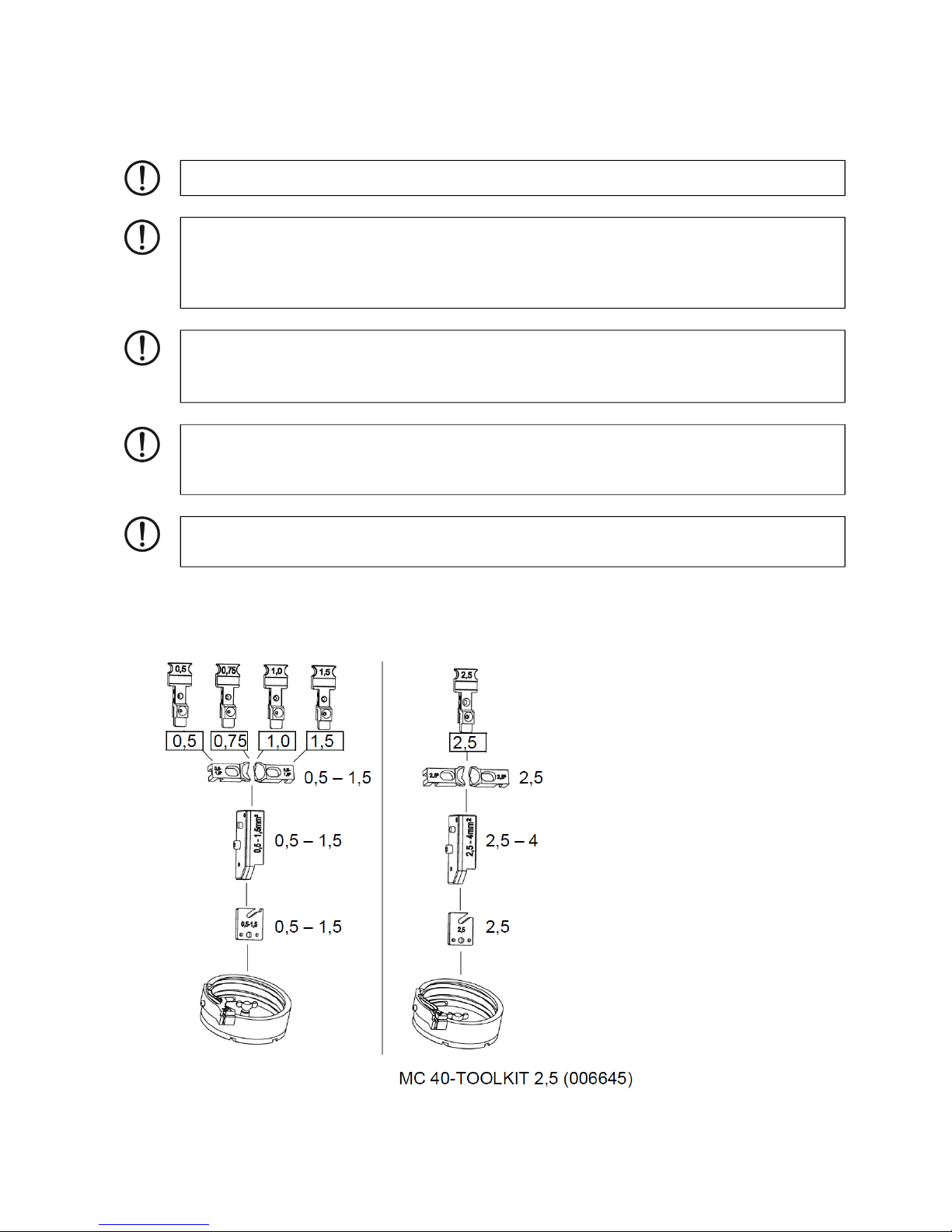

2.2 Suitable ferrules and retrofit kits ......................................................................................... 6

2.3 Overview of the operating components .............................................................................. 8

2.4 Control Panel ..................................................................................................................... 9

3 Starting up and operating ....................................................................................................... 10

3.1 Selecting the installation site ............................................................................................ 10

3.2 Determine the cross section............................................................................................. 10

3.3 Stripping and crimping ..................................................................................................... 11

4 Maintenance ........................................................................................................................... 13

4.1 Daily care ......................................................................................................................... 13

4.2 Adjusting and changing the stripping blade ..................................................................... 14

5 Retrofitting ............................................................................................................................... 16

5.1 Changing the cross section ............................................................................................. 1 6

5.2 Changing the crimping length .......................................................................................... 18

6 Troubleshooting ...................................................................................................................... 19

6.1 FC-2#0 does not run after being switched on .................................................................. 19

6.2 Start process is not being initiated ................................................................................... 20

6.3 Conductor insulation is not removed completely ............................................................... 2 0

6.4 Ferrule in-feed is disrupted .............................................................................................. 21

A Technical appendix .................................................................................................................. 22

A1 Technical data ................................................................................................................... 22

A2 EC Declaration of Conformity ............................................................................................ 23

A3 Spare parts ........................................................................................................................ 24