AS 30 WeedHex 140

AS 30 WeedHex 160

EN Operating instructions

Contents

EN Operating instructions 4

1.1 Intro uction....................................................................................4

1.1.1 Note well..............................................................................4

1.1.2 Safety Regulations.................................................................5

1.1.2.1 User restrictions...........................................................5

1.1.2.2 Safe han ling of fuel ..................................................5

1.1.2.3 Inspection before use...................................................6

1.1.2.4 Procee with caution uring operation..........................6

1.1.2.5 Prior to brushing..........................................................6

1.1.2.6 Procee with caution uring brushing............................6

1.1.2.7 When work is complete .............................................7

1.1.2.8 Procee with caution uring maintenance an repair......7

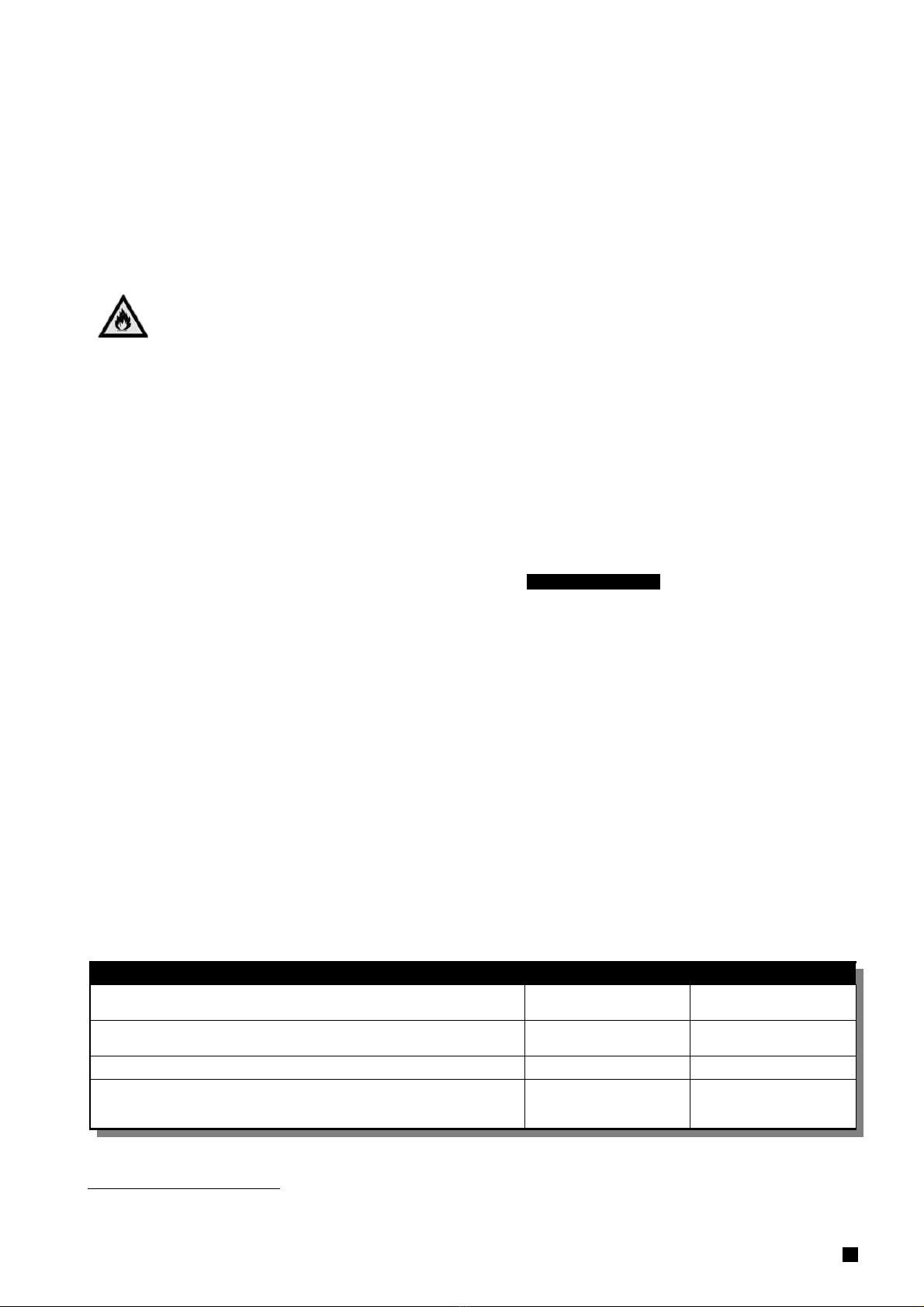

1.1.3 Noise an Vibrations Levels....................................................7

1.1.4 Safety Pictograms..................................................................8

1.2 Basic Information............................................................................8

1.2.1.1 Technical Data.............................................................8

1.2.1.2 Engine Information......................................................8

1.2.2 Description of the Machine an its Components.......................9

1.3 Operating Instructions.....................................................................9

1.3.1 Machine Assembly.................................................................9

1.3.1.1 Assembly proce ure.....................................................9

1.3.2 Device transport..................................................................10

1.3.3 Engine Starting....................................................................10

1.3.4 Activating the brush.............................................................10

1.3.5 Stopping the brush..............................................................11

1.3.6 A justing position of the wheels...........................................11

1.3.7 Machine Operation...............................................................11

1.3.7.1 Mounting of the guar ................................................11

1.3.7.2 Selecting the position of the wheels.............................11

1.3.7.2.1 Brushing in corners...........................................11

1.3.7.2.2 Open area brushing..........................................11

1.3.7.3 Manner of evice operation.........................................12

1.3.7.3.1 Brushing in corners...........................................12

1.3.7.3.2 Open area brushing..........................................12

1.4 Maintenance, Care, Storage...........................................................12

1.4.1 Machine Lubrication.............................................................12

1.4.1.1 Engine Oil Change......................................................12

1.4.1.2 Lubrication Points.......................................................13

1.4.2 Brush change......................................................................13

1.4.3 A justing irt scrapers.........................................................13

1.4.4 Engine Air Filter Maintenance...............................................13

1.4.5 Belt Gears...........................................................................14

1.4.5.1 A justing of tension pulleys........................................14

1.4.5.1.1 Tension pulley for primary belt..........................14

1.4.5.1.2 Tension pulley for secon ary belt.......................14

1.4.5.2 V-belt change............................................................14

1.4.6 Spark plug...........................................................................14

1.4.7 Servicing intervals................................................................15

1.4.8 Troubleshooting...................................................................16

1.4.9 Storage ..............................................................................17

1.4.9.1 Spare parts................................................................17

1.4.9.2 Wear parts.................................................................17

1.4.9.3 Machine washing an cleaning....................................17

1.4.10 Disposal of Packaging an the Machine at the En of its Service

Life..............................................................................................17

1.4.11 Warranty...........................................................................17

1.5 Accessories...................................................................................17

The manufacturer stipu ates its right to implement technical changes an innovations not affecting the machine's operability an

safety. These changes may not show in these Operating Instructions.

The machine version shown may not correspon to the actual stan ar machine version.

Typographical errors reserve .

1.1 Introduction

Dear customer!

Congratulations on your purchase. You have acquire a reliable quality pro uct by “AS-Motor Germany”. This pro uct has been

manufacture accor ing to up-to- ate manufacturing metho s an in line with comprehensive quality assurance measures. Only when you

are satisfie with your evice, we have achieve our goal.

Rea these operating instructions carefully so that your evice operates smoothly an you an others are safe from any hazar s.

If you have questions concerning your evice, please contact your ealer or call our Customer Service.

For international partners, please visit our website https://www.as-motor.com

“AS-Motor Germany” wishes you much joy with your new evice.

1.1.1 Note well

The evice is exclusively inten e for cleaning of pave surfaces an e ges covere with moss an wee s.

Only use attachments an tools authorize by “AS-Motor Germany”.

Any use excee ing this purpose is ina missible. The manufacturer is not responsible for any amage resulting from such unauthorize

use. Observe the require maintenance an repair measures.

The user of the evice is responsible for acci ents or injury to other persons or amage to their property!

In particular, the evice must not be use :

- On any roa s.

- as a unit in a system for any type of work tools an tool sets that are not approve by “AS-Motor Germany”.

- for sweeping or mowing on unpave surfaces.

The user must read these Operating Instructions an follow all the machine operating instructions in or er to prevent any health risks

or property amage to the user or other persons.

The safety instructions specifie in these operating instructions o not cover all the possible con itions an situations, which may occur

in practice. Safety factors, such as a reasonable approach, care, an caution are not inclu e in these operating instructions, but it is

assume that every person using the machine or oing any maintenance work on it is able to sufficiently use them.

Only mentally an physically fit persons may operate this machine. Shoul this machine be use commercially, the owner of the

machine is boun to provi e operators with work safety training an instruct them regar ing its operation, an keep recor s of such training

. They must a so assess their work in accordance with the re evant oca egis ation.

If any information containe in the manual is unclear to you, please contact your dea er3 or irectly the device manufacturer.

3

Filll in the ealer’s a ress in the table in the hea ing of this manual (unless alrea y fille in by the ealer).

4

Revision 09/2020