□Accessories

This product comes supplied with a pair of carbon brush and two bits.

□ Bits(one set per screwdriver) Bit specifications

ψ5 5mm Hex shank(PS series) 1/4’’ Hex shank

Tip

No.

Tip

Dia

d P# Tip

No.

Tip

Dia

d P# Tip

No.

Tip

Dia

d P#

Available

Screwdriver

Model

#1 5ψ7W3844 #1 5mm 7W5848 #1 ψ4.5 7W6744

#2 5ψ7W3864 #2 5mm 7W5868 #2 ψ6.0 7W6964 ASA-7000/PS

ASA-7000S/(PS)

#2 5ψ7W3864 #2 5mm 7W5868 #2 ψ4.5 7W6764

#2 5ψ7W3864 #2 5mm 7W5868 #2 ψ6.0 7W6964

ASA-7500/PS

ASA-8000/S

ASA-8000S(PS)

#2 ψ6.0 7W6964

--- --- --- --- --- --- #2 ψ6.0 7W6964

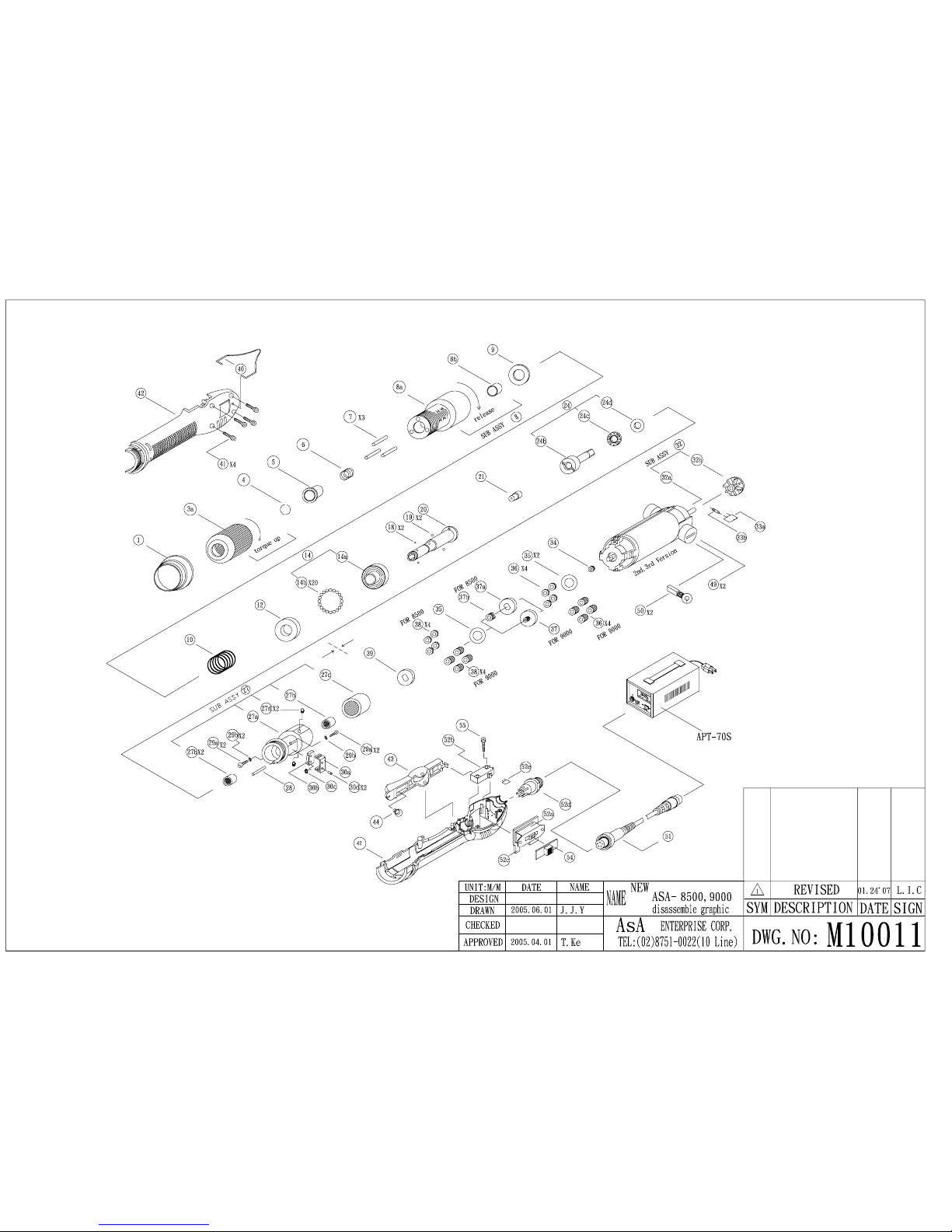

ASA-8500/PS

ASA-8500S/(PS)

ASA-9000/S

ASA-9000S/(PS)

□Power supply(optional)

Dimension mm

Model L W H

Operation

volt

(AC)

Output

volt

(DC)

Weight

(g/lb) Approval Available

Model Packing

100-120V

APS-30 154 84 52 220-240V 30V/5P

(constant) 620/1.36 UL,cUL,CE ASA-7000

ASA-8000

110-120V

APS-30U 154 84 52 220-240V 30V/6P

(constant) 620/1.36 Pending ASA-7500

Together

With

Driver

115V

APT-70 220 118 96 230V 30V/5P 3700/8.1 UL,cUL,CE ASA-7000

ASA-8000

115V

APT-70S 220 118 96 230V 30V/6P 3700/8.1 Pending ASA-7500

ASA-8500

ASA-9000

Separated

From

Driver

․APS-35A/APS-35E are switching circuit power supplies. They are light and small, consume little electricity

and supply stabile voltage.

․Stabilizer accessories:2 locking ties, 2 pieces of double-sides tape(only for APS-35A/APS-35E)

□Before use, read the following

□ Use the correct voltage: Carefully check the voltage shown on the power supply and this manual and

determine the correct voltage. Only plug the unit into a power source of the correct voltage.

□ Determine the appropriate torque range: choose the correct screwdriver for the torque you will require. To

lengthen product life, avoid long-term high torque use.

□ Make sure the screwdriver is undamaged: If the power code is scraped or damaged, it should be immediately

unplugged and replaced to avoid electric shocks or a short circuit that could result in fire.

□ Use in an appropriate work environment: To ensure safety, do not use in high temperature, high humidity

environments or near flammable materials. Keep the power cord away from tools or equipment that might

scrape or melt it.

□ When plugging in or unplugging the power cord, hold the plug firmly. Never pull on the cord.

□ Method of operation and important points

□ Brace fastened objects securely-Before operation, refer to “torque settings” item to determine the

appropriate torque , and adjust the screwdriver to the appropriate torque. Make sure that the

fastend objects are securely braced, and then begin operation. This procedure will avoid

hazardous rapid rotation of the fastened objects due to excessive torque or insufficient bracing.

□ Driving and removing screw: Before operation, set forward/reverse switch properly. To drive

a screw, set the switch to the forward(FOR) position. To remove a screw, set it to the reverse(REV) position.

Press the screwdriver onto the screw perpendicularly to being operation. Note: Don’t operate the FWD/REV

switch when the motor is running.

□ Torque settings: Use the regulating handle or torque reaction ring (ASA-8500, 9000 only) to set the torque.

Turning it in a clockwise direction into the screwdriver will increase the torque. Turning it counterclockwise

out of the screwdriver will decrease the torque.

Note: The engraved markings on the engraving ring are for reference only and do not indicate torque output.

Torque output can only be determined by repeated testing with a torque meter or hand-held spanner torque

meter. To prevent your torque setting from being changed, we can provide a torque cover (optional) which

covers and secures the regulating handle.

□ Bit insertion: Use your finger to depress the slide sleeve into the screwdriver and insert an appropriate bit.

When the slide sleeve is released, the bit will be automatically engaged.

Note: Do not hammer the bit in or pull it out forcibly.

□ Secure screwdriver during operation: During operation, hang the screwdriver up securely (as from balancer) in

order to prevent it from being knocked down and suffering external cracking, internal damage, or a snapped

power cord.

□ Start and stop: For lever start type. The motor begins running when the lever is depressed and stops when it is

released. For push to start type. When the screwdriver is pressed onto a screw perpendicularly, inwards

pressure from the screwdriver bit engages the power switch, and the motor begins running. When the pressure

on the screwdriver is released, the bit and power switch revert to their original positions and the motor stops

running.

□ When the selected torque is reached: This product features an internal clutch assembly. When a screw is driven

and the selected torque is reached, the clutch assembly will automatically disengage and a ‘click’ will be heard.

At this point, even if the ‘trigger’lever or depress force is not released, the power to the motor will be

automatically cut off.

Note: When driving screw, grasp the screwdriver firmly in order to prevent upwards recoil generated by the

clutch release from forcing the screwdriver bit edge form the screw slot and damaging slot.

□ When removing screws: when a previously driven screw cannot be removed using the same torque that it was

driven with, raise the torque setting. After the screw is removed, return the regulating handle to its original

setting. To simplify this operation, note the number ‘click’sounds generated as the regulating handle is turned.

When removing a screw, if the required torque is higher than the screwdriver’s output torque, the clutch may

not disengage, causing the user’s hand and arm to be twisted. In this case immediately set the forward/reverse

switch to “STOP” to cut the motor power and prevent injury.

□ Operational frequency: suggest the operational frequency 1/4”(ON/OFF)second, the total screws

7000pcs/8hours, don’t over our operational frequency suggest, and avoid the inside parts of screwdriver serious

damage. If everyday work 8hours upward, please use two screwdriver by turns, protect the life of screwdrivers.

□ Changing the carbon brush: Open the carbon brush cover by turning it counterclockwise with a coin or standard

screwdriver(width5-7mm.)Remove the used carbon brush and insert a new carbon brush of the same

specifications in the empty space. To complete the operation, close the carbon brush cover tightly by turning it

clockwise. Then remove the carbon brush fastener

Note:

․When changing the carbon brush first unplug the screwdriver. Use a factory specification carbon brush.

․The notch on the carbon brush surface must face into the direction of the rotor rotation

MOTOR

MOTOR

ROTOR

NOTCH

CARBON

FACE

CONVEX POINT

CONVEX POINT

GUIDE NOTCH

GUIDE NOTCH

RECEPTACLE

(SCREWDRIVER SIDE) (SCREWDRIVER SIDE)

RECEPTACLE

6P PLUG5P PLUG