Asahi/America, Inc. 7 Shop 12 O&M Manual

2102D

Engineering & Rental - 14 pages

6.

Initial Heating

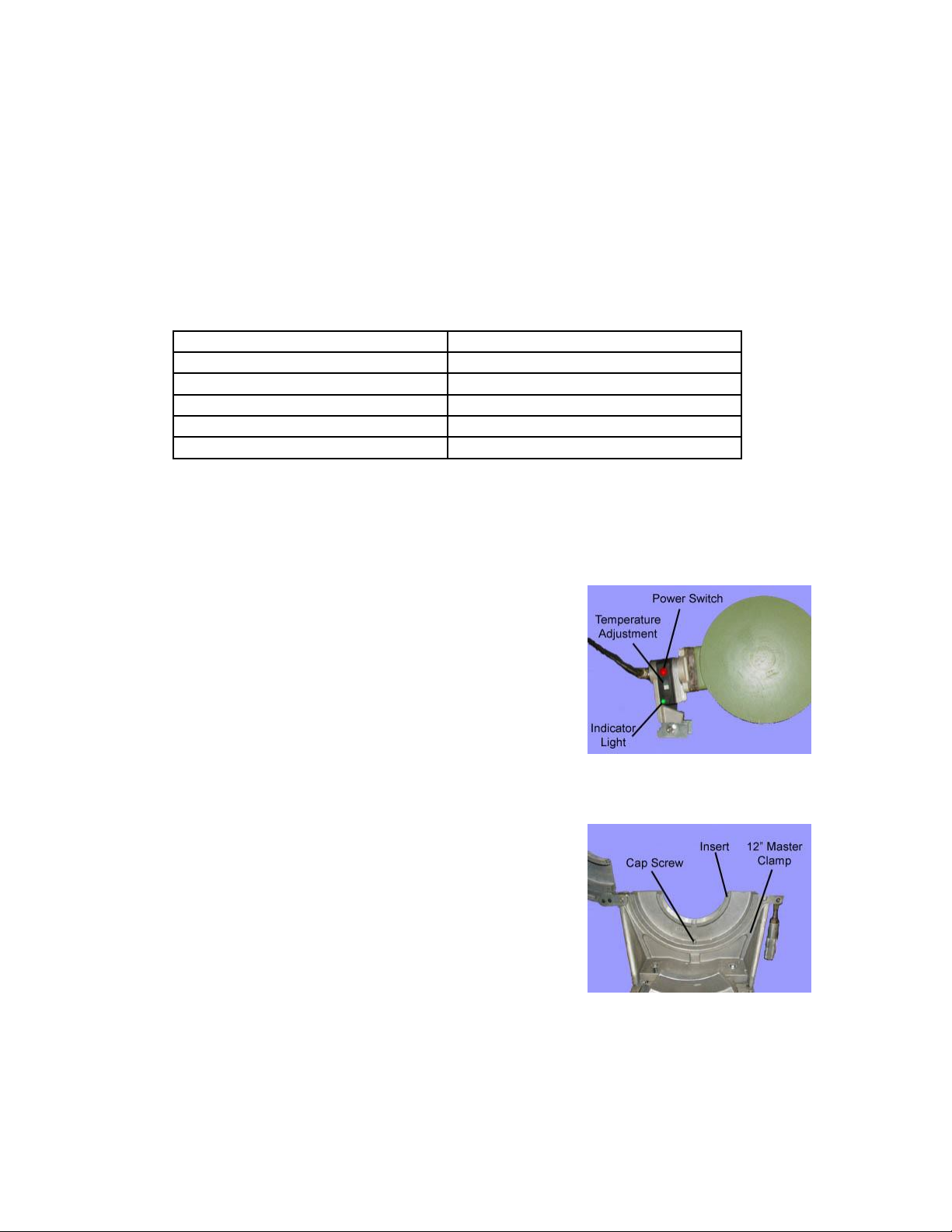

A. Check whether the heating plate has reached the working temperature (see heating

element temperature setting or the welding parameters). The working temperature

is reached when the control lamp goes out (thermostatically controlled) or if the

lamp blinks in short intervals (electronically controlled).

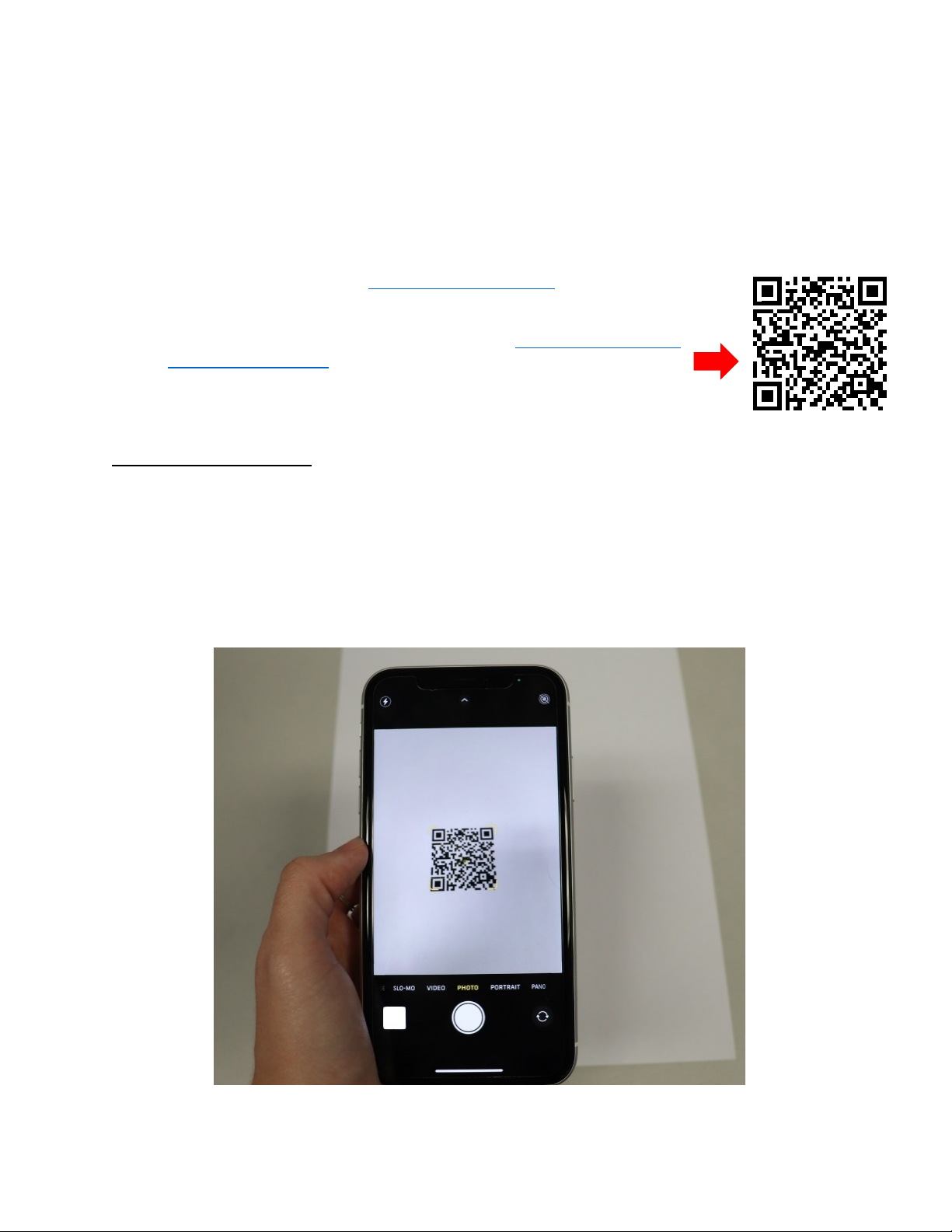

B. Place the heating plate between the two ends the

pipe to be welded. Bring the pipe ends against the

heater applying the proper initial melt pressure

(see charts at the end of this manual for proper

welding pressures). Lock the clamps in place with

the locking nut.

C. Watch for a continuous bead to form around both

pipe ends (see pipe manufacturer or DVS

standards for size).

D. Lower pressure until the proper melt pressure is reached (almost zero).

Note: If the clamps are moved too far in this direction, the pipe may

move away from the heater, causing a bad weld.

7.

Heat Soak

A. With the pressure almost at zero, begin to time the heat soak time (see

welding parameters). It is important to assure that the pipe ends remain in full

contact with the heating element.

8.

Change Over Time

A. Move the pipe ends apart. Remove the heating element and then bring the pipe

end back together.

B. Bring the pressure back to the original weld pressure and lock the clamps in

place. These steps must be performed within the allowable change over time.

9.

Cooling Time

A. Keep the machine under pressure until the cooling time has expired.

B. For PP and HDPE, cooling time can be reduced by 50% under the following

conditions:

I. Prefabrication under workshop conditions

II. Low additional pressure when unclamping

III. No additional pressure during further cool down

IV. System will not see pressure until cool down is complete