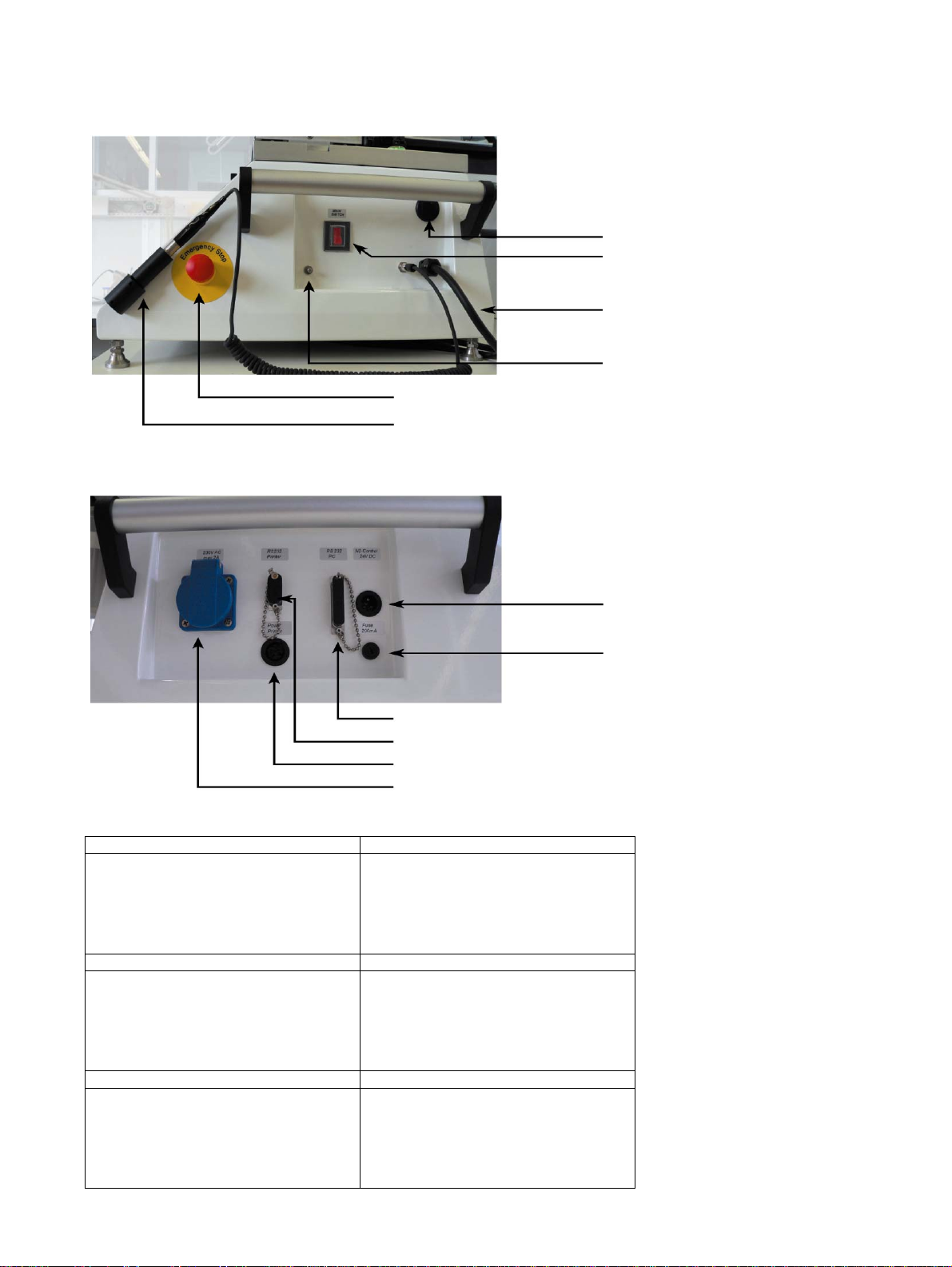

Make sure all connectors are tight in their sockets and make sure

that the machine is operated only if

the conditions for safe and intended

use are met (see also section 2)

Important

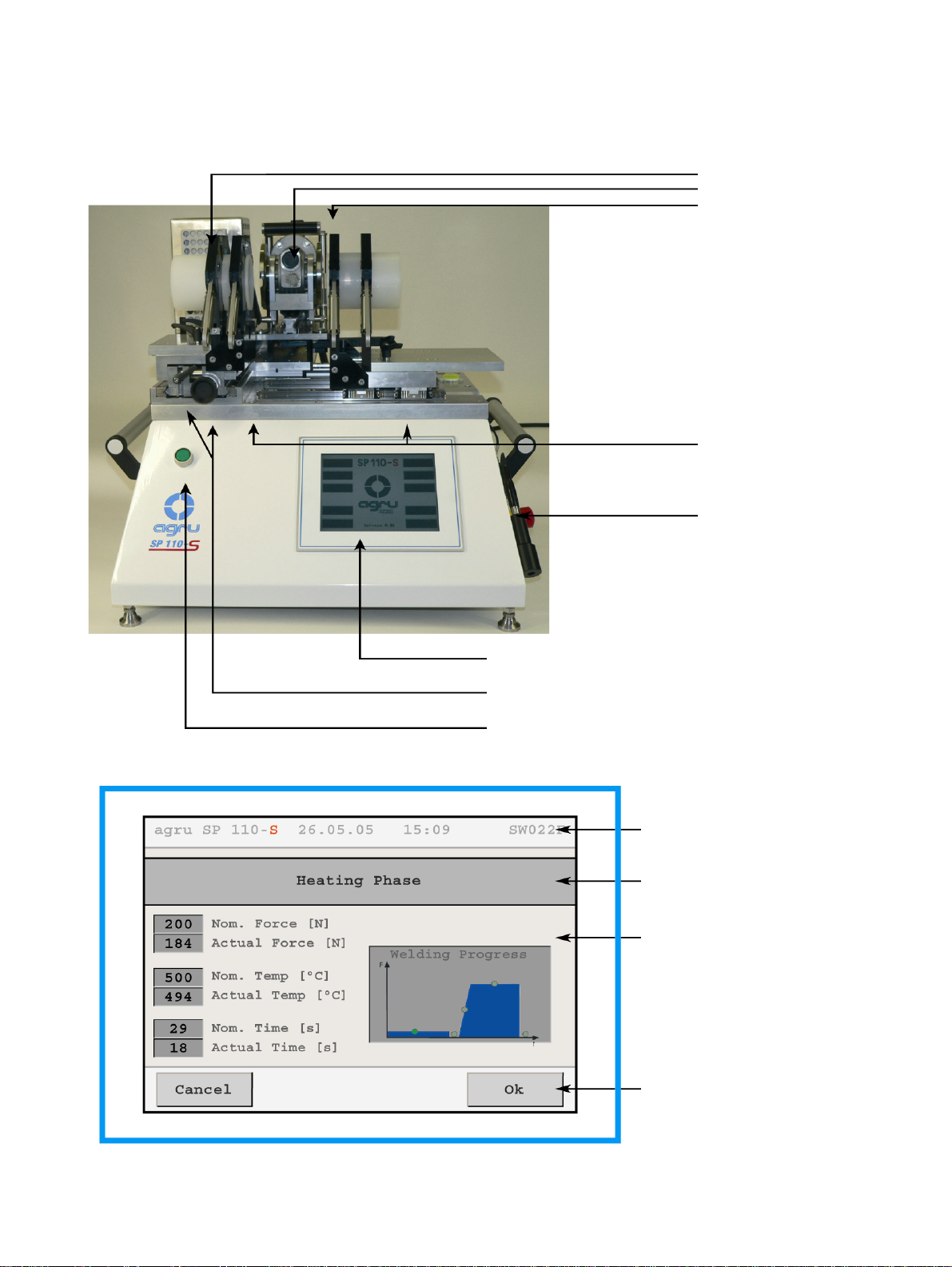

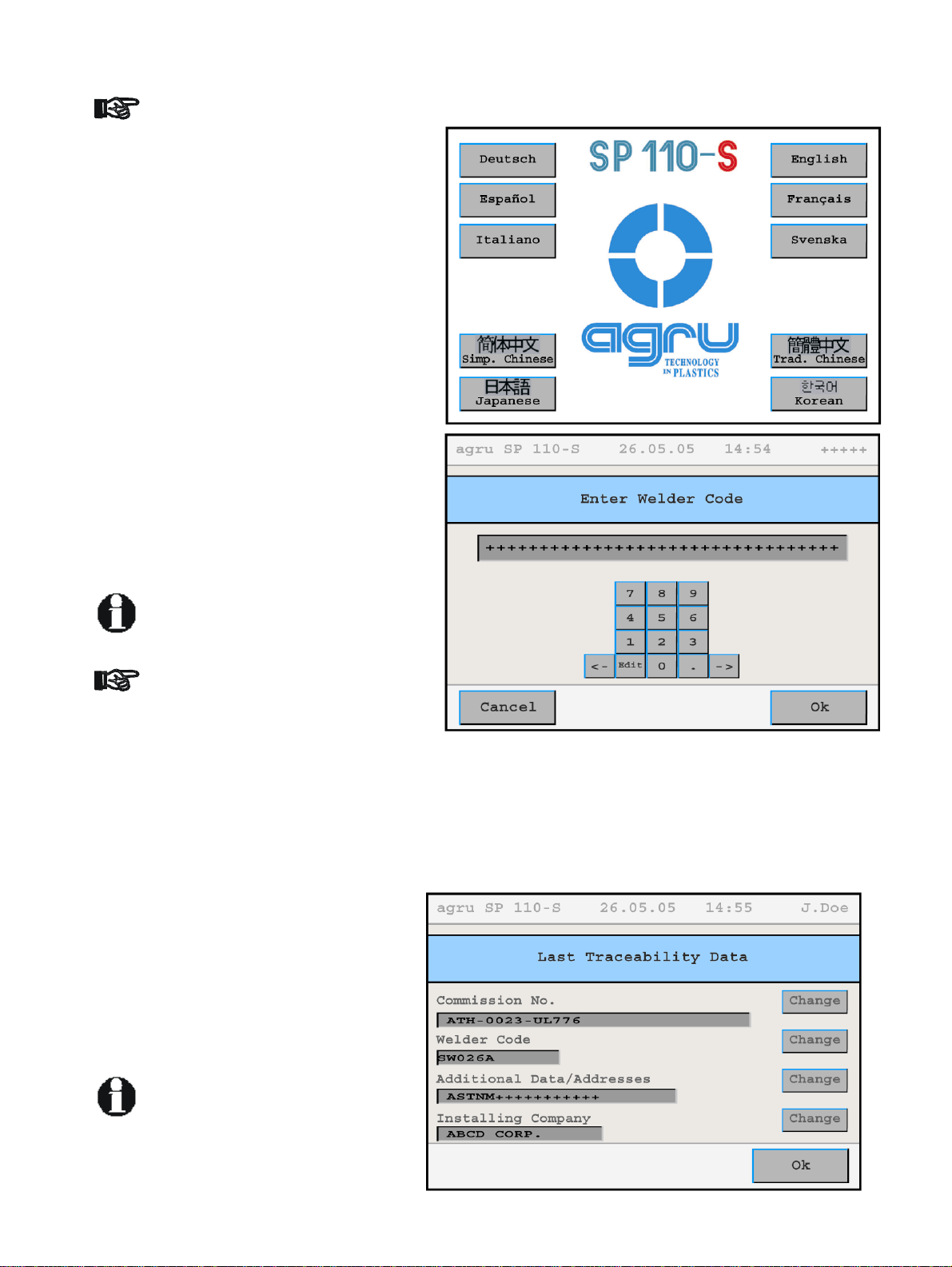

Display 1

After preparing the machine for

welding and connecting the power supply cord

to the mains power supply, the machine is

turned on using the On/Off switch. The wel-

come screen, as reproduced in Display 1, ap-

pears on the touchscreen panel. Touch the

appropriate flag to select the display language

that the machine will use.

After the language was selected, the machine

takes the user to the welder code entry

screen. Without a valid welder identification

code, it is impossible to start welding processes

on the machine, since the heating element re-

fuses to heat up unless a valid code is entered.

Info

Enter the welder identification code by typing it

on the touchscreen and saving it to memory by

touching the “Ok” button. If a bar code for the

welder code is available, you can also read it

from the bar code using the scanning wand.

All inputs for which a bar code is

available can be entered from the

bar code using a scanning wand.

Entering data on the touchscreen

must always be performed with the

bare finger. Using objects (ballpoint

pens, screwdrivers, etc.) may cause

unrecoverable damage to the surface of the touchscreen.

Display

Info

Important

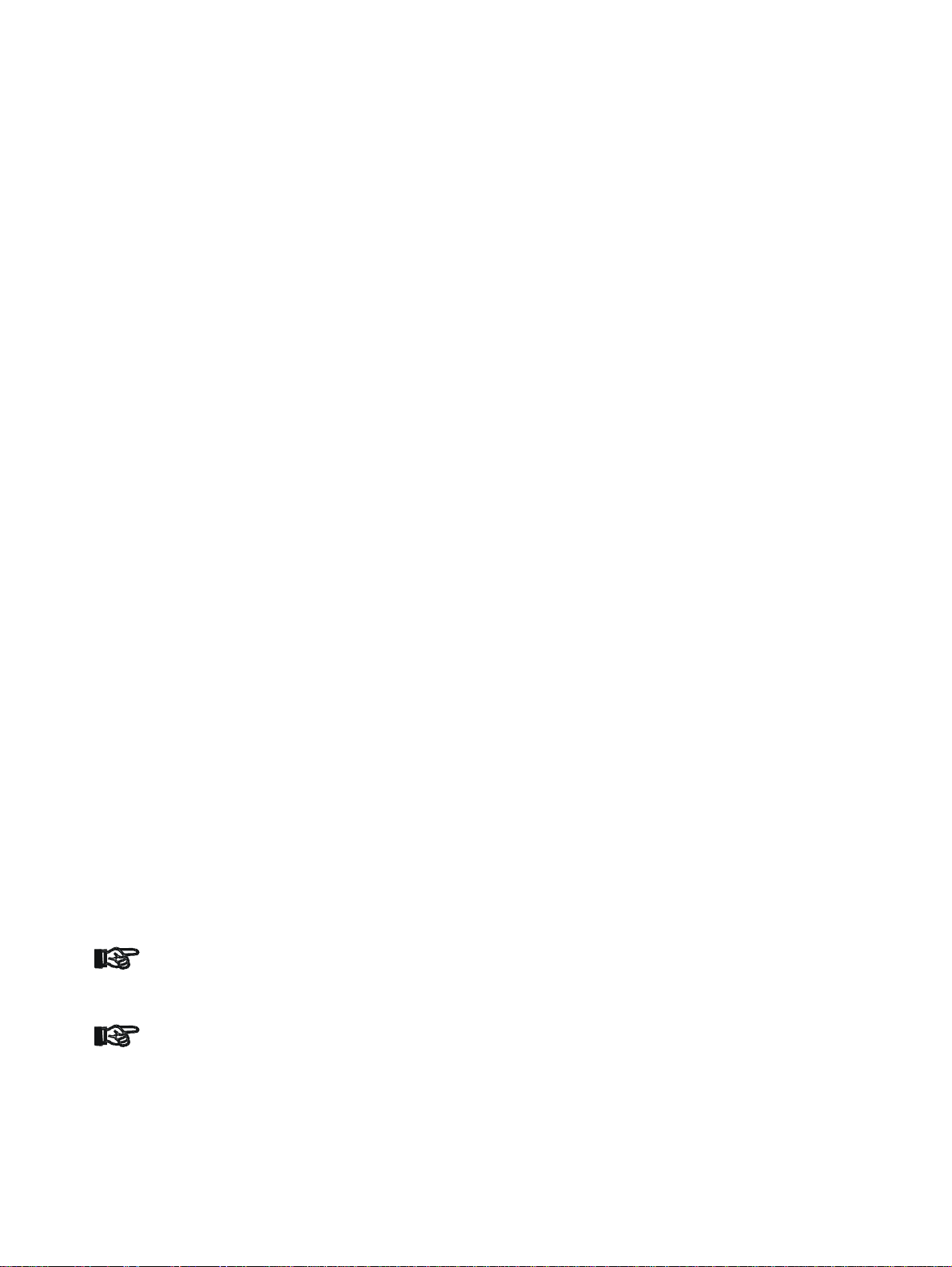

4.2 Entering Traceability Data for the Joint

After the welder identification code was entered, the traceability data for the

joint have to be entered.The machine displays the traceability data for the

last joint that was welded (see Display 3), which can be re-used for the next

welding operation by simply touching the “Ok” button.

If traceability data are not the same as for the

last joint, change the data that are different

by touching the appropriate “Change” button.

Depending on the kind of data you want to

change, the machine displays either a

numeric keypad (see Display 2) or an

alphanumeric keyboard (see Display 4). To

confirm and save your data input to memory,

touch the “Ok” button.

Depending on the software

version installed in your machine,

some screens may differ slightly

on your machine from the

reproductions in this manual.

10 agru SP-110S User’s Manual Version December 2006

Display