4

English

• Thebicycle must be equipped with wheel reflectors

(both front and rear) and pedal reflectors. Make sure

that all reflectors are clean and visible.

• When riding in darkness, ensure that you have properly

functioning lights, both front and rear.

• Remember that rules and regulations for bicycles

will differ from country to country. This may include

regulations regarding front, rear and side reflectors,

along with front and rear lights. It is your responsibility

to familiarise yourself with therules and regulations that

apply in your country.

• Always ride in thesame direction as traffic flow.

Never ride against traffic.

• Always follow thelocal traffic regulations.

• Show consideration in traffic. Don’t ride close to

pedestrians, horse riders or thedisabled.

• Never use loose fitting clothing or similar apparel that

can get caught in thebicycle chain or wheels.

• Changes to thebicycle or its components can make it

unsafe to use. Each part and component of thebicycle

has been carefully chosen and tested. Thesafety

aspect of safety-critical components, accessories and

spare parts is not always obvious. Therefore, use only

original or compatible parts when making repairs or

when fitting accessories.

• Special tools and specialist knowledge make it easier

to assemble thebicycle and to make theinitial settings.

If you are at all unsure, this should be performed by

somebody with theappropriate competence.

• Incorrectly performed mechanical work can make

thebicycle unsafe to use. Something as simple as

tightening ascrew or bolt to theincorrect level of

torque may result in some part of thebicycle breaking,

causing you to lose control of thebicycle and have

anaccident.

• We recommend that all servicing, repairs and fitting

of accessories are performed by aperson with

therequisite competence and experience. Your safety

depends on thecorrect performance of maintenance.

• Any tampering or modification of theelectrical system,

frame, forks or other components can make thebicycle

dangerous to use.

• Acomponent that is not adapted for thebicycle, or

that has been incorrectly fitted, can subject thebicycle

to major stress with theresulting risk of personal injury

or material damage.

• Before you fit any accessories onto thebicycle, or

make changes to any part, it is your responsibility to

ensure that thechange you intend to make is both

compatible and safe.

• If you wish to use a child seat, make sure not to

exceed the max. weight allowed on the bike rack.

• Use a child seat that conforms to EN 14344.

• Adhere to the instructions that come with the child seat.

• Fitting achild seat will change thecentre of gravity of

thebicycle, which can make it difficult to manoeuvre.

• If a child seat is used, make sure that the maximum

total weight limit of the bicycle is not exceeded.

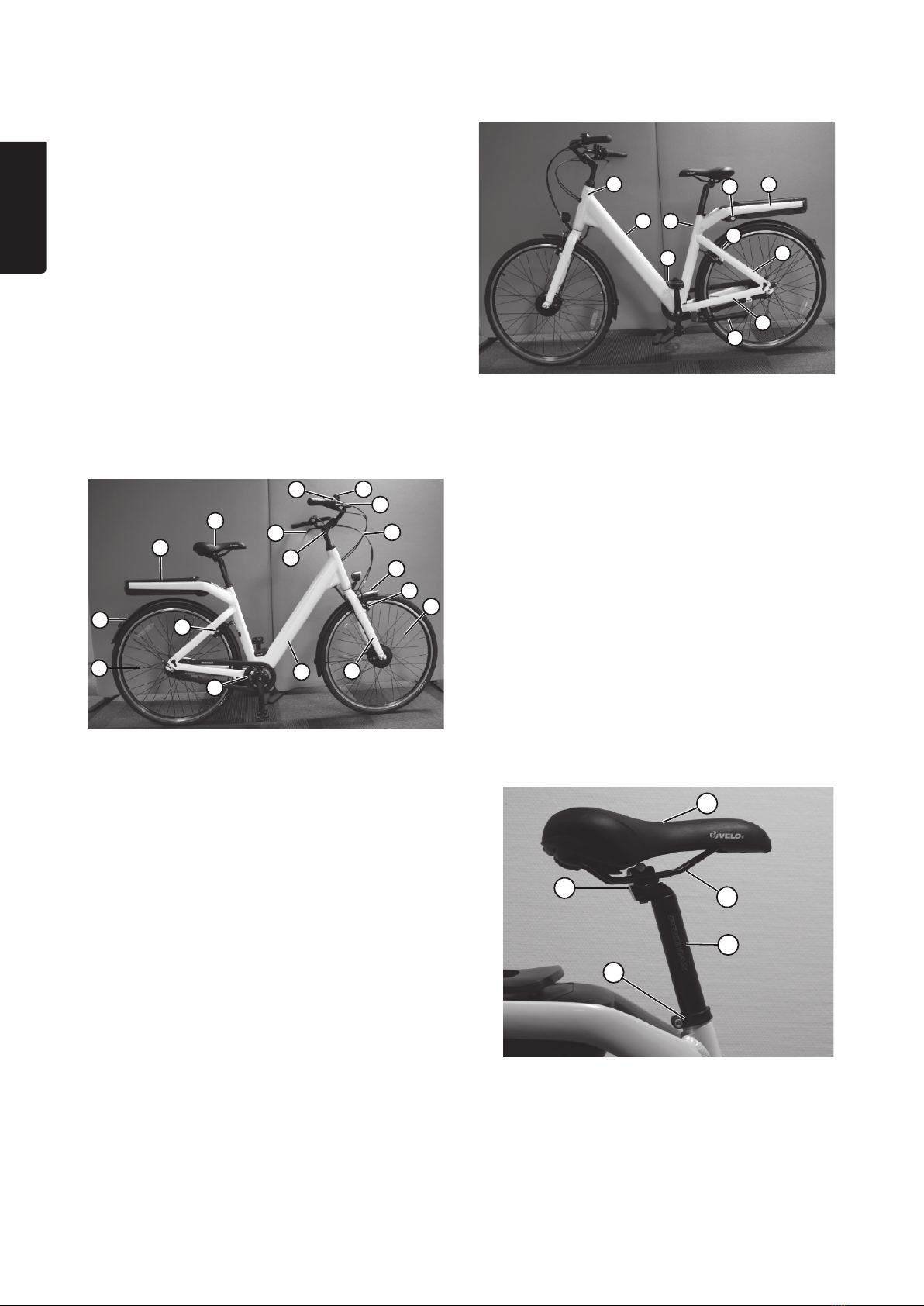

• If theposition of thesaddle has not been correctly

adjusted to suit you, or if thesaddle does not suit

your body type, you risk causing damage to your

nerves and blood vessels. Adjust theposition of

your saddle if you experience pain or discomfort.

Special safety instructions for

electric bicycles (EPAC)

Warning:

The charger is designed for indoor use only.

• Please follow the instructions on the label of thecharger.

• Never connect thepoles of thebattery or thebattery

charger using electrically conducting objects.

• Never expose thebattery or thebattery charger to

vibrations or bumps beyond that extent which occurs

during normal use.

• Thebattery may only be charged using thesupplied

charger.

• Thebattery and battery charger must never be

exposed to liquids or fire. Risk of explosion!

• When charging thebattery, do not touch either

thebattery or thebattery charger with damp hands.

• Neither thebattery nor thebattery charger may be

opened for any form of repair or modification.

• Never use adamaged battery.

• Never allow thebattery or thebattery charger to be

handled by children.

• During charging, thebattery charger must never be

covered.

• Never use thebattery charger if its cables have been

damaged.

• Never charge thebattery in temperatures below

0°C or above 40°C.

• Always remove thebattery from thebicycle when

performing any form of maintenance, service or

mechanical settings to thebicycle. Thesteering system

of theelectric bicycle must never be modified nor used

in any way other than that described in themanual.

Insurance

Your electric bicycle is to be insured in thesame way as

aregular bicycle. Contact your insurance company for

more information about insurance conditions.

Instruction manual

Important:

Please read theentire instruction manual before use and

then save it for future reference.

Theinstruction manual provides you with essential

knowledge about your electric bicycle, with regard to:

• safety

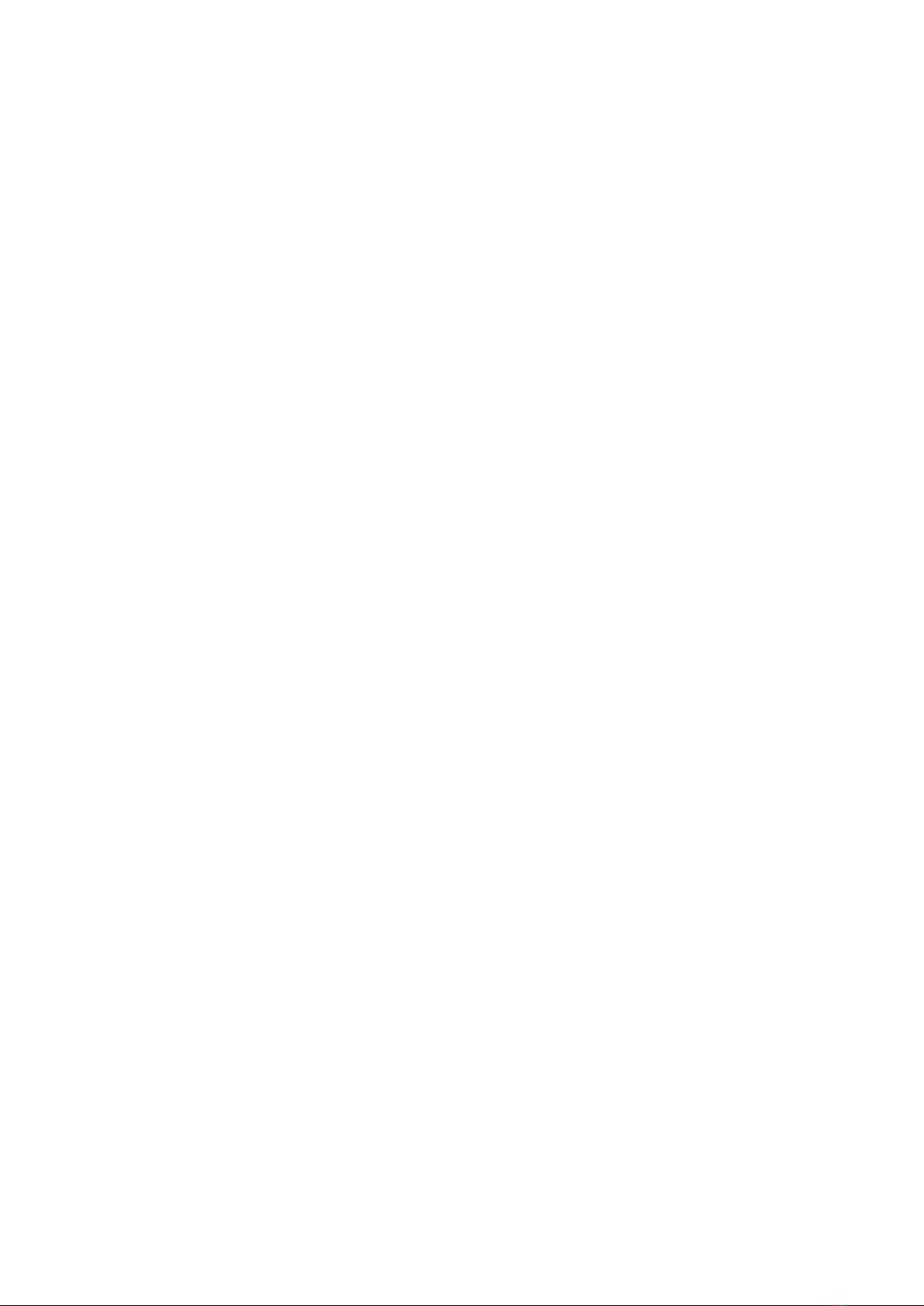

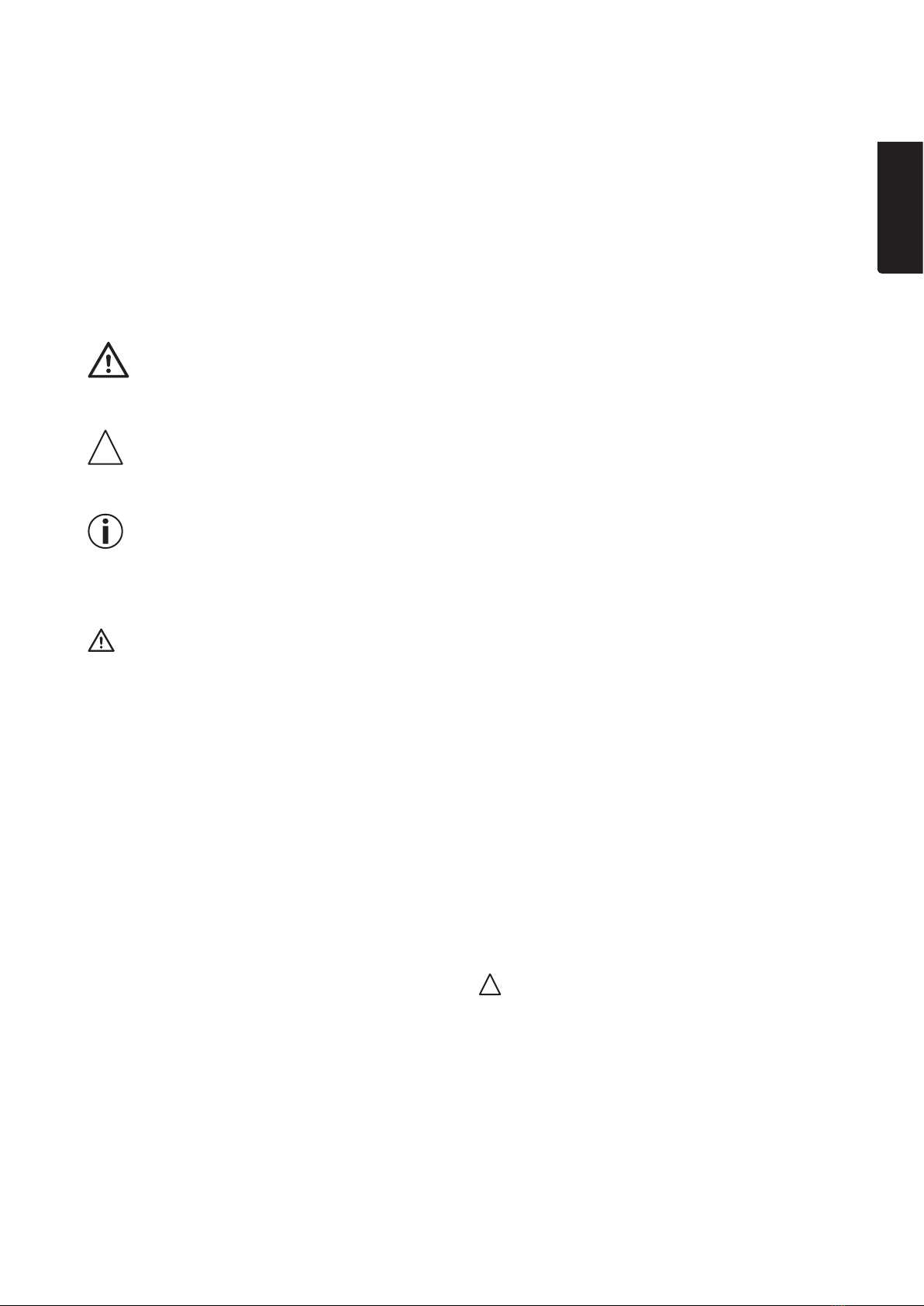

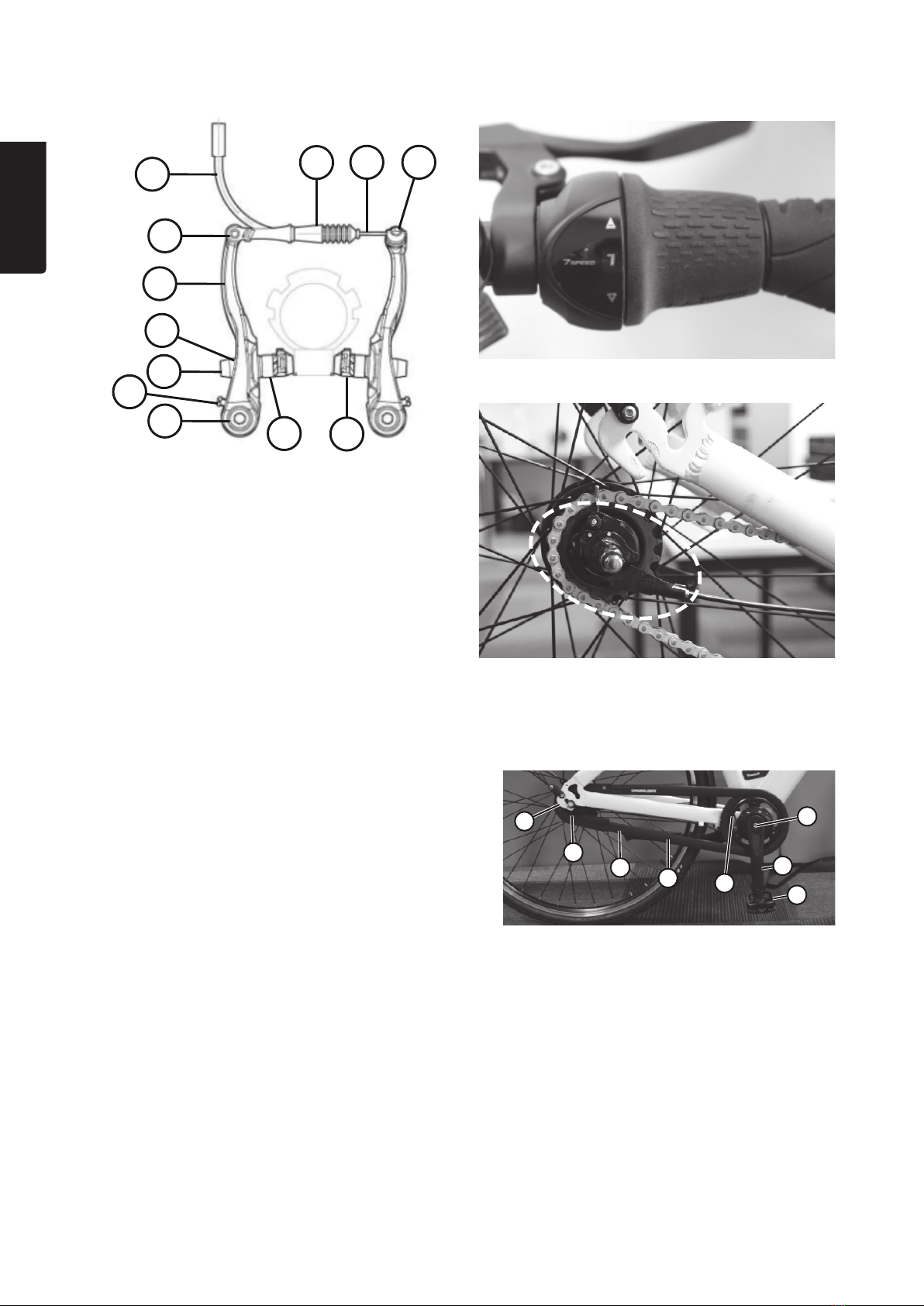

• functions and parts

• assembly

• settings and adjustments

• usage

• care and maintenance.