3

English

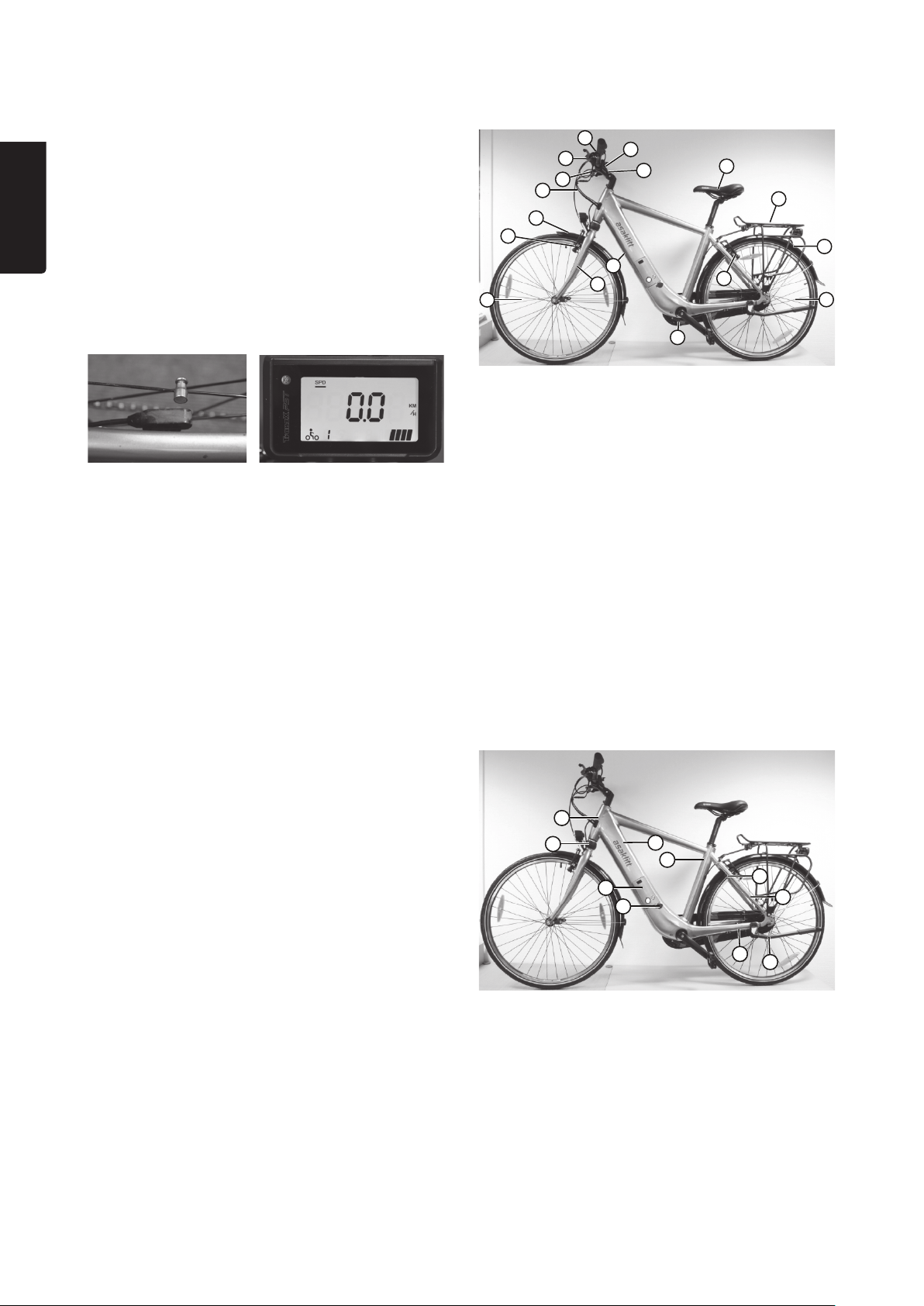

Asaklitt Urban Electric Bicycle

Art.no 31-9779, 31-9780 Model Urban

Please read theentire instruction manual before use and then save it for future reference.

We reserve theright for any errors in text or images and any necessary changes made to technicaldata.

In theevent of technical problems or other queries, please contact our Customer Services (see address details on theback).

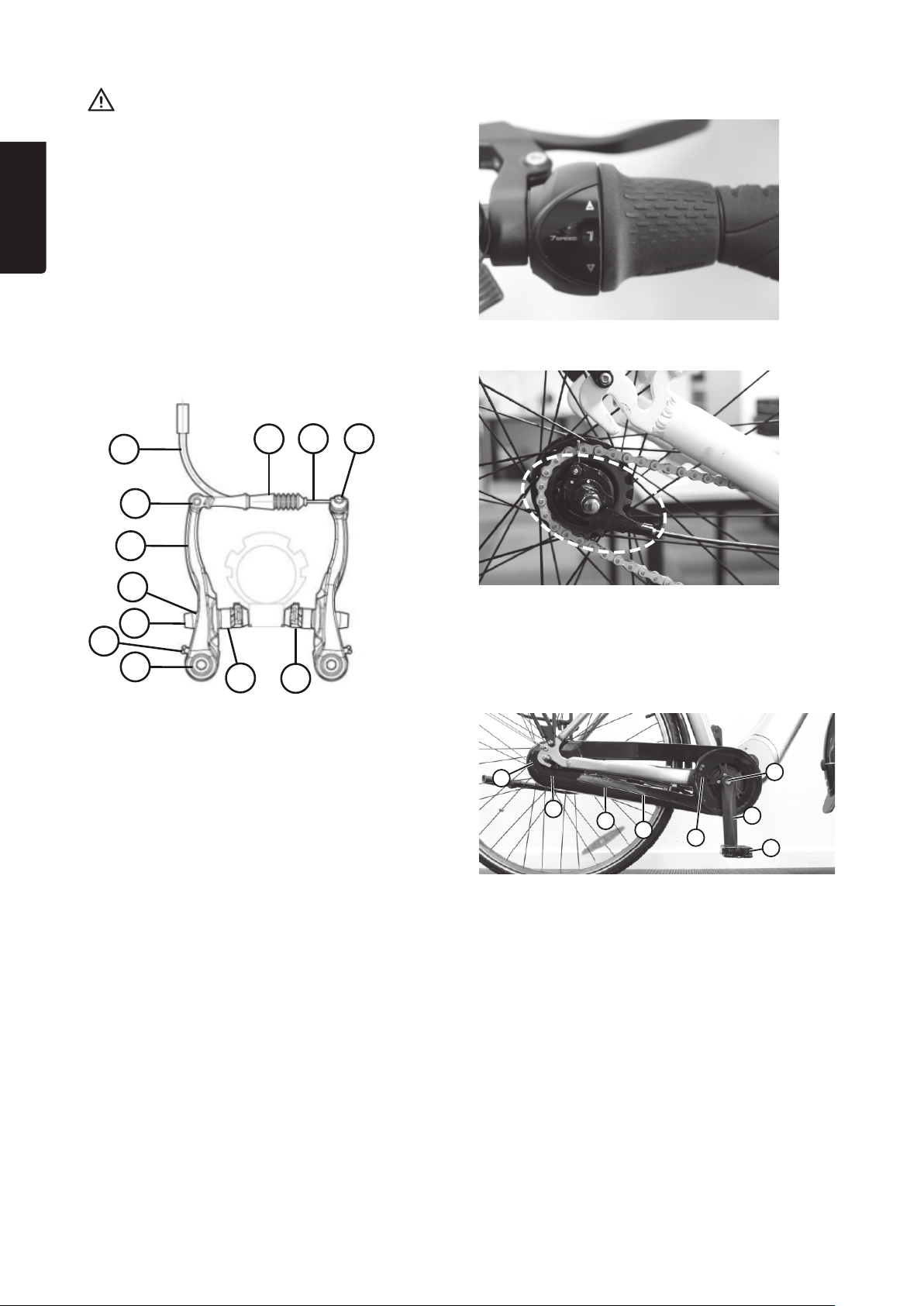

• When brakes are applied, thebrake pads wear against

thewheel, which means that thewheel rims and brake

surfaces become worn overtime. Therate of wear

and tear depends on several factors,e.g. theway

in which thebrakes are used, road conditions, how

often thebrake blocks are replaced, and how often

thebrake blocks and wheels are cleaned. Thesides of

thewheel rim can eventually become so thin that they

collapse, which can result in serious personal injury

and material damage. Checkthewheels regularly, and

replace wheels that show signs ofwear.

• Brakes and braking components can become veryhot.

Donot touch them during, or shortly after,use.

• Anopen, unplugged end on thehandlebar could cause

injury in theevent of anaccident. Checkthat theends

of thehandlebars are covered by thehandgrips or with

handlebarplugs.

• There may be sharp points on theteeth of thecogs

and sprockets.

• Thepedals may have sharp edges and serrations.

• Moving parts can cause cutting and crushing injuries,

even resulting in thebreaking ofbones.

• Clamps and other parts may cause crushing injuries.

• If you cycle in conditions with poor visibility (such as in

fog, twilight or at night), others many find it difficult to

see you, and therisk of anaccident increases. Always

use lights (front and rear) when cycling in poorly lit

conditions where visibility islow.

• You expose yourself to increased risk if you use

thebicycle in away that is not recommended,e.g. ifyou:

- Perform jumps with thebicycle.

- Cycle over tree roots and branches, stones, or

other similar objects.

- Cycle on challenging terrain.

- Cycle in anunusual manner.

• Anexcessive load can cause theframe or other parts

to break, thus increasing therisk of injury. Minimise

therisk of injury and damage by using thebicycle in

thecorrect manner.

Important:

• Tighten all nuts, bolts and screws but do not overtighten.

Useatorque spanner to ensure thecorrect level of

torque (where such levels are stated).

• Adjust thebicycle so that it fits you and your bodytype.

• Always conduct asafety check beforeusing.

• Always use aproperly adjusted and fitted helmet.

• Always keep both hands on thehandlebars.

• Wear clothing that makes you visible to your fellow

roadusers.

• Thebicycle must be equipped with wheel reflectors

(both front and rear) and pedal reflectors. Makesure

that all reflectors are clean and visible.

Safety

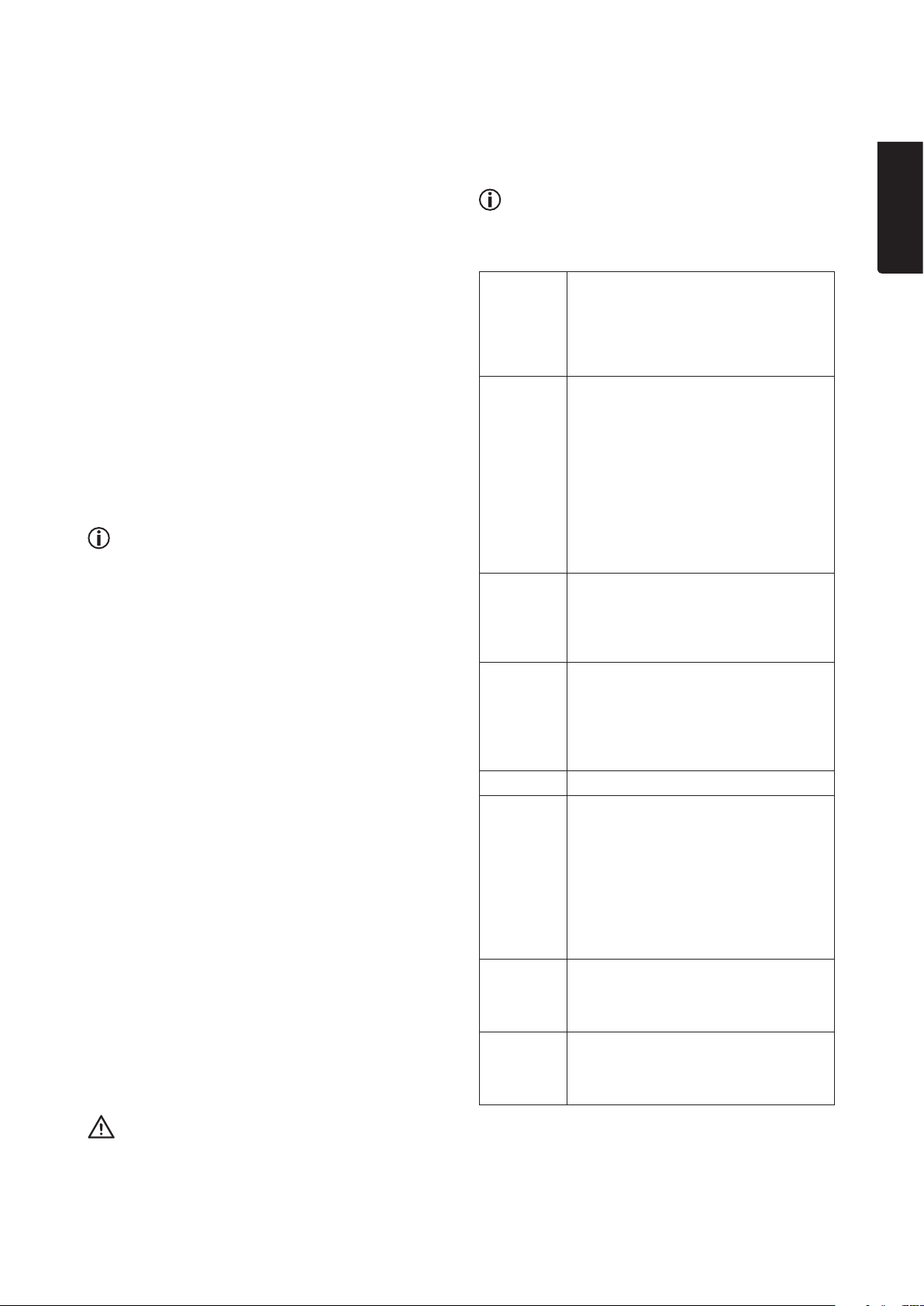

Symbol guide

Warning: Warning for apossible hazard which

could lead to serious personal injury and/or

damage to theproduct if thewritten instructions

are not followed.

Important: Warning for apossible hazard which

could lead to minor personal injury and/or

damage to theproduct if thewritten instructions

are not followed.

Note/Information.

General safety instructions for

bicycles

Warning:

• Thebicycle is designed to be ridden on normal roads

and not for terrain or competitiveuse. Anyform of use

other than that described in this instruction manual

can lead to aserious risk for personal injury or material

damage.

• Never brake hard using thecoaster brake in slippery

conditions,e.g. on gravel, ice, snow or wet tarmac.

• It may become difficult to control thebicycle in wet or

windy weather conditions. Reduce your speed and

exercise greater caution, or use analternative form of

transport.

• Always brake using therear brakes first before

attempting to use thefront brakes. Thisespecially

applies if road surfaces are slippery.

• For steep hills several braking methods should be

combined, otherwise using thecoaster brake may

cause therear wheel to overheat.

• As with all mechanical components, thebicycle

is subject to wear and high stressloads. Different

materials and components may react to wear or

stress fatigue in differentways. Allcomponents have

acertain lifespan and if thelife of acomponent has

been exceeded, it may suddenly fail causing possible

injury to theuser. Anyforms of cracks, scratches or

changes of colouring in highly stressed areas indicate

that thelife of thecomponent has been reached and it

should be replaced.