INSTALLATION AND MAINTENANCE INSTRUCTIONS

P152 PLUS

SERIES

P152

Table of Contents

1. Notifications ...................................................................................................................................................... 3

1.1. Technical Support Contact .................................................................................................................................................................................3

1.2. Disclaimer ..................................................................................................................................................................................................................4

1.3. Symbols and Conventions ..................................................................................................................................................................................4

1.4. Safety ...........................................................................................................................................................................................................................5

2. Associated Documentation .............................................................................................................................. 6

2.1. Product Information ..............................................................................................................................................................................................6

3. Introduction ....................................................................................................................................................... 7

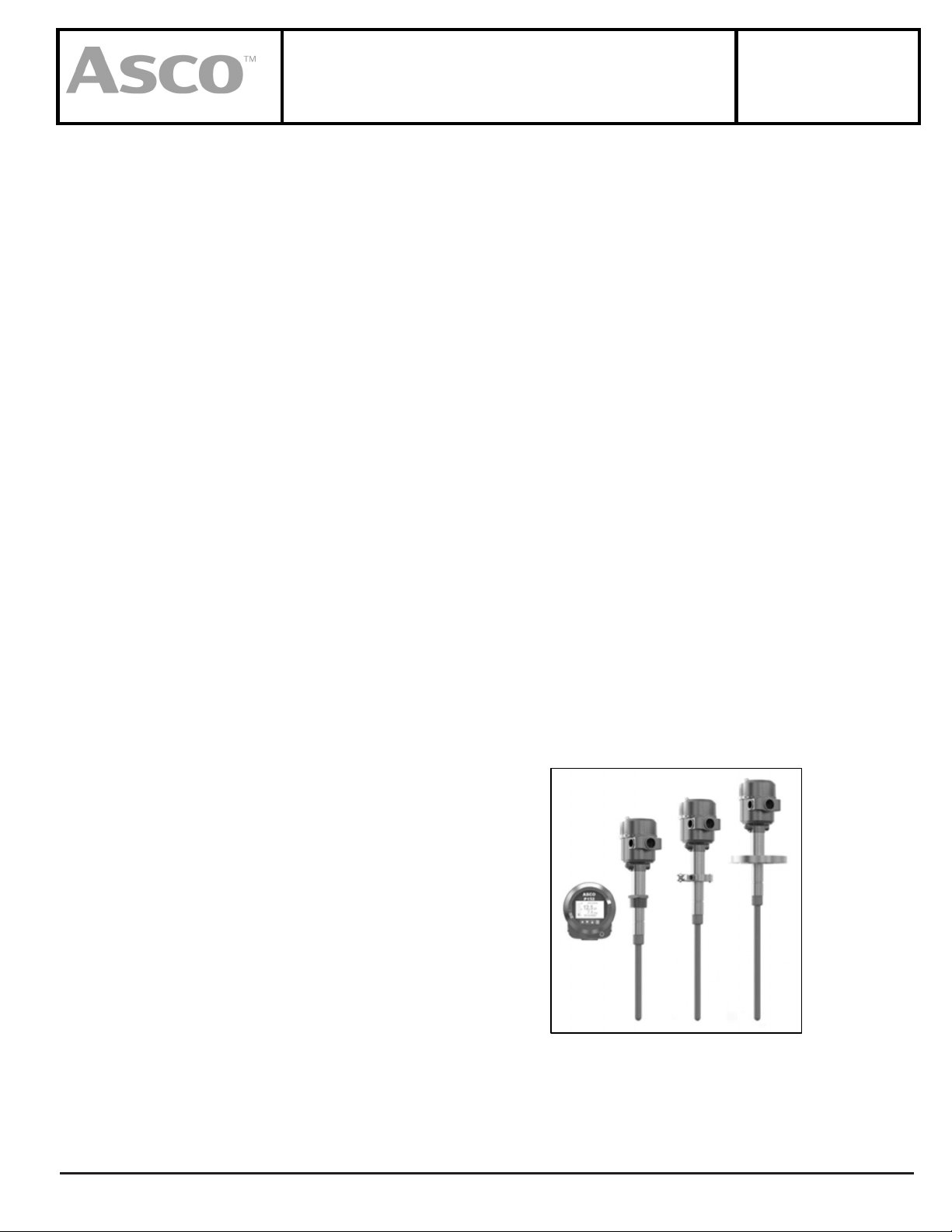

3.1. P152 PLUS Overview .............................................................................................................................................................................................7

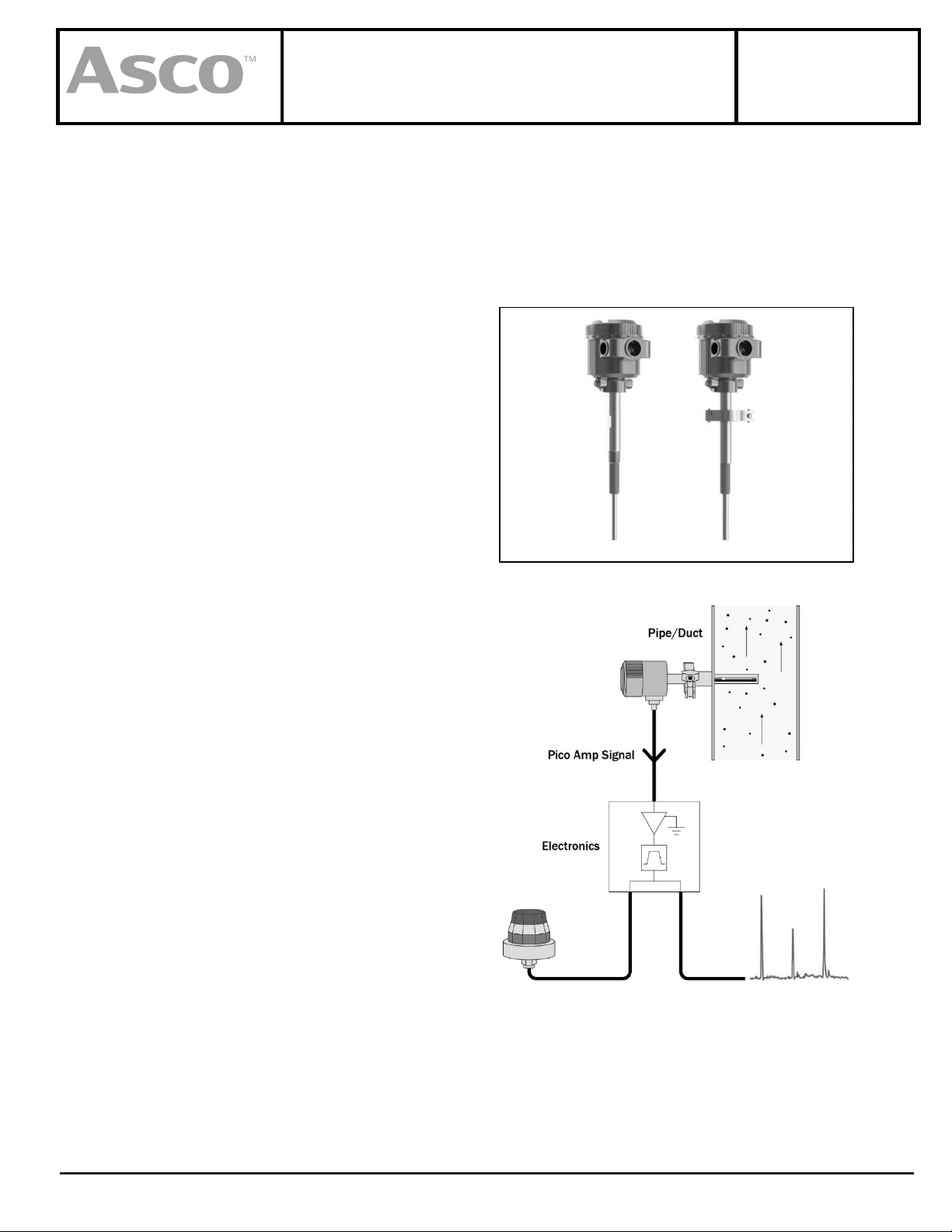

3.2. Design .........................................................................................................................................................................................................................9

3.3. Components .......................................................................................................................................................................................................... 11

3.4. Technical Data ...................................................................................................................................................................................................... 12

4. Installation ....................................................................................................................................................... 15

4.1. Location................................................................................................................................................................................................................... 16

4.2. Process Mounts .................................................................................................................................................................................................... 18

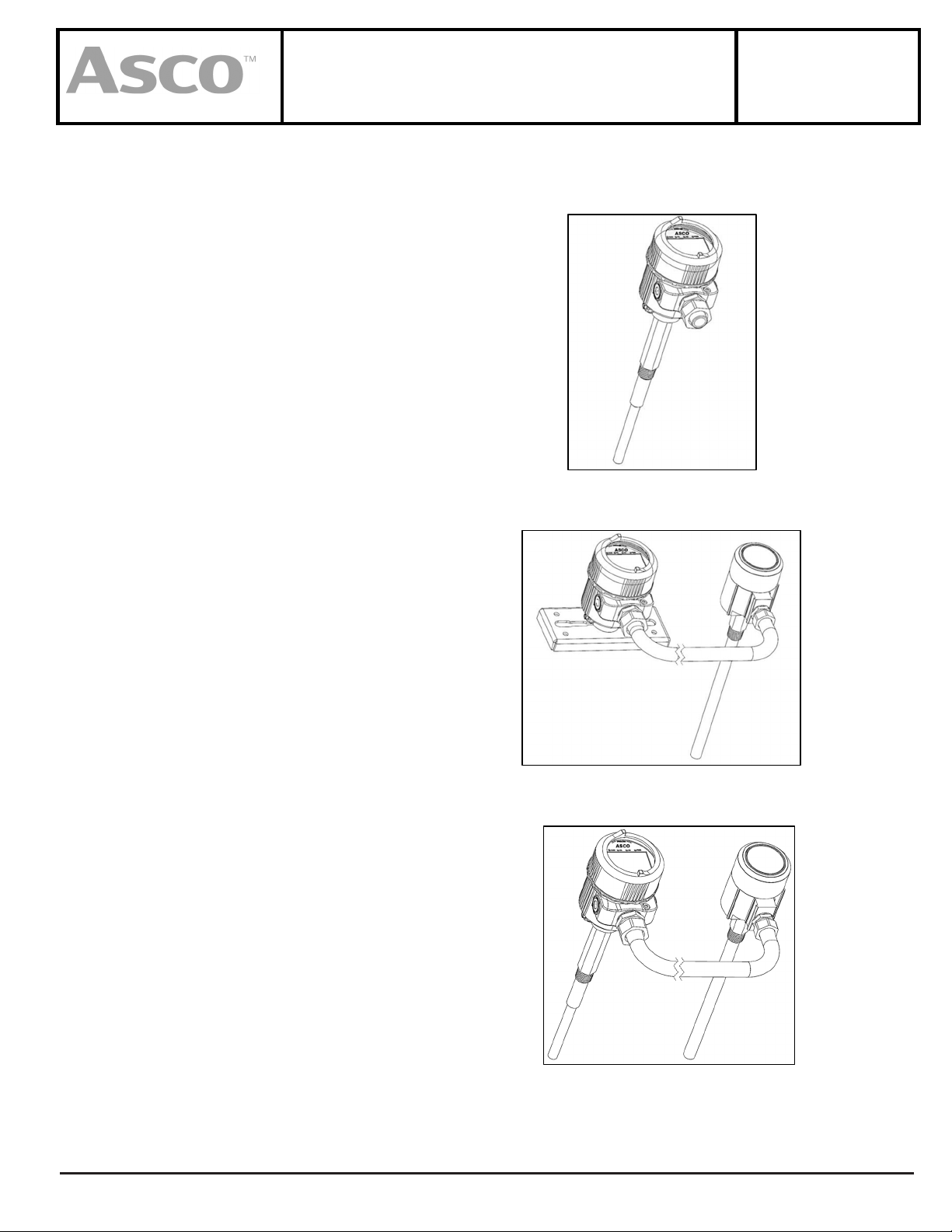

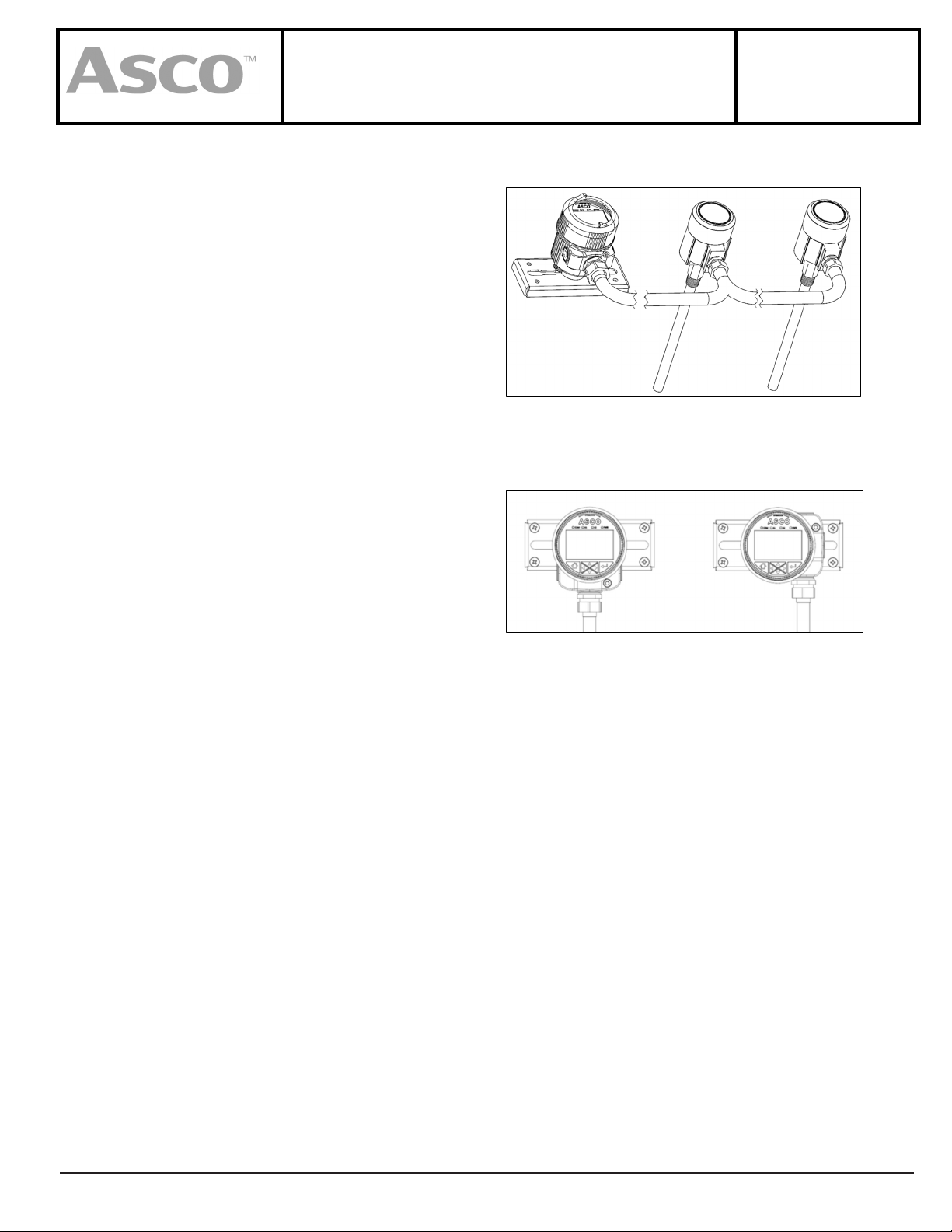

4.3. Sensor Mounting ................................................................................................................................................................................................. 20

4.4. Remote Electronics Mounting ........................................................................................................................................................................ 22

4.5. Test Port .................................................................................................................................................................................................................. 23

5. Wiring ............................................................................................................................................................... 24

5.1. Terminal Connections........................................................................................................................................................................................ 25

5.2. HART Wiring .......................................................................................................................................................................................................... 29

5.3. Particulate Sensor Wiring (Remote Version Only) .................................................................................................................................. 30

6. Operation ......................................................................................................................................................... 31

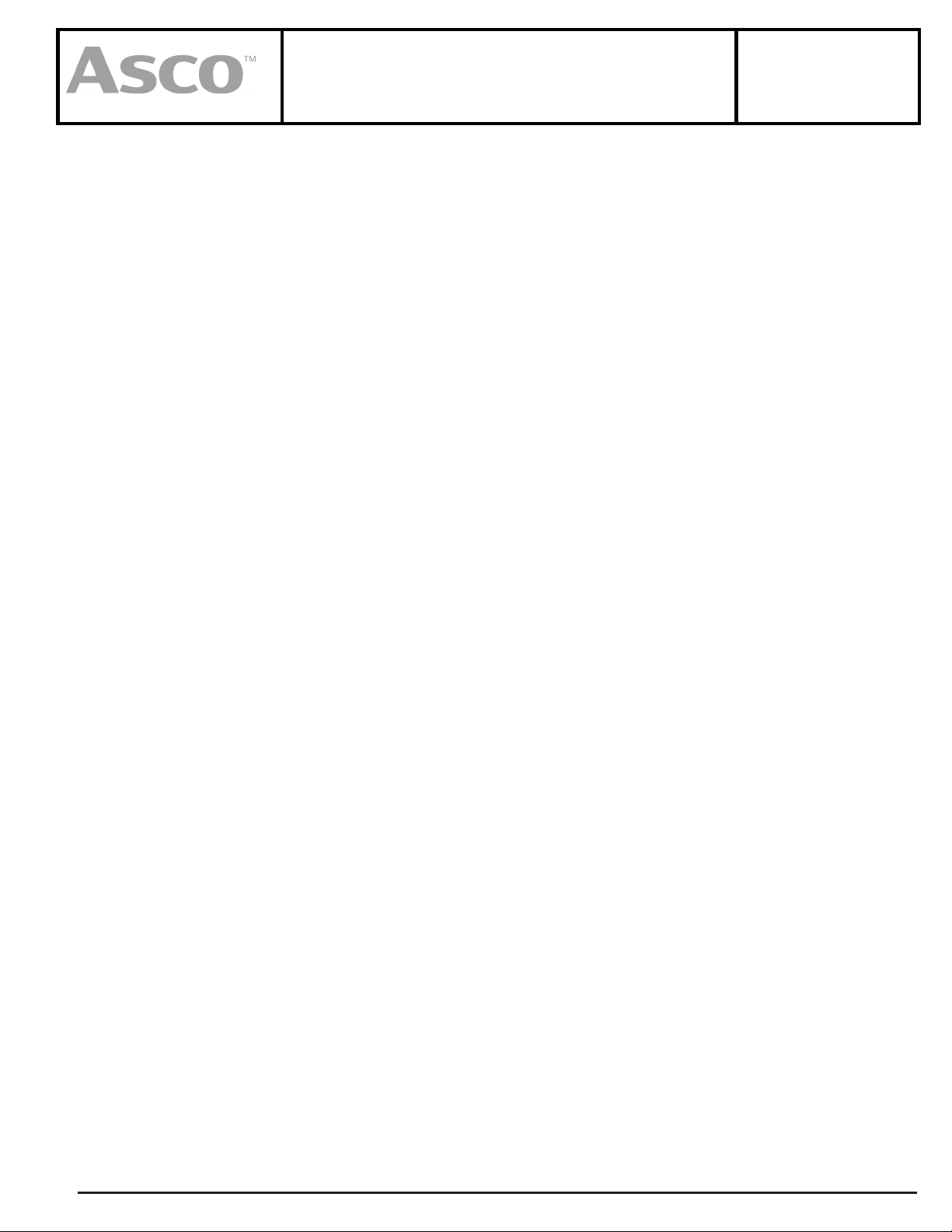

6.1. User Interface ........................................................................................................................................................................................................ 31

6.2. Home Screen ......................................................................................................................................................................................................... 32

6.3. Process Screens .................................................................................................................................................................................................... 33

6.4. Active Alarm Screen ........................................................................................................................................................................................... 35

6.5. Alarm Details Screen .......................................................................................................................................................................................... 35

6.6. Diagnostic Screen ................................................................................................................................................................................................ 36

6.7. User Login .............................................................................................................................................................................................................. 36

6.8. Setup Menu ........................................................................................................................................................................................................... 37

7. Commissioning ................................................................................................................................................ 38

7.1. Measurement ........................................................................................................................................................................................................ 38

7.2. Alarms ...................................................................................................................................................................................................................... 39

7.3. Relay Outputs ........................................................................................................................................................................................................ 40

7.4. Analog Output ...................................................................................................................................................................................................... 40

7.5. Diagnostic Signaling .......................................................................................................................................................................................... 42

7.6. HART ......................................................................................................................................................................................................................... 42

7.7. Bluetooth and DeviceLINK Mobile App ...................................................................................................................................................... 53

7.8. Display ..................................................................................................................................................................................................................... 54

7.9. System ..................................................................................................................................................................................................................... 54

7.10. Information ............................................................................................................................................................................................................ 56

7.11. Alarm Setpoint Guidance ................................................................................................................................................................................. 56

8. Diagnostics....................................................................................................................................................... 58

8.1. Automatic Self-Checks ...................................................................................................................................................................................... 58

ASCO Valves® All Rights Reserved. I&M V_10026_AA

E406787 - 11/2023 www.emerson.com/ASCO Page 1 of 65