Hold 15 sec.to

start the engine

generator and to

transfer the load

to emergency.

Press to cancel the

active exercise period

(stops engine now or

after cooldown) See

page 5–1.

Hold 5 sec.toset

20 min. engine exercise

period immediately (engine

starts) and weekly thereafter.

³blinks slowly when

button is released (set)

and during 20 min.

exercise period.

³blinks rapidly when

button is held 5 sec.

while being set

Lights show position of transfer switching device. Lights show the sources accepted.

Light for built–in

engine exercise timer:

Seepage5–1

for complete

instructions

Figure 2–1. Membrane controls and indicator lights.

³stays on after engine

stops (exerciser is

enabled for weekly

operation)

SECTION 2 SEQUENCE OF OPERATION

2 --- 1

Transfer To Emergency

Thesequenceforloadtransferto

emergency source begins

automatically when normal

source voltage falls below the

preset dropout point or when

Transfer Test button is pressed. An

under voltage condition on any

phase of the normal source is

detected by the sensor.

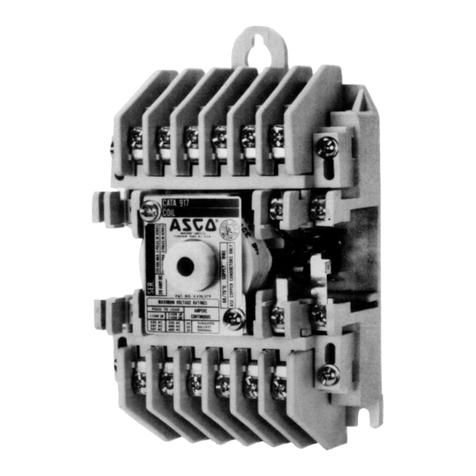

When the normal

source voltage fails

or the Transfer Test

button is pressed, the

SE relay de-ener-

gizes and relay NR

begins its timing

cycle (1 or 3 seconds,

momentary normal

source outage delay). The NR relay is provided with a time

delay on dropout to override momentary outages and

prevent nuisance starting of the engine-driven generator.

If the normal source voltage returns above the sensor

dropout setting before the time delay expires, the NR

relay timing cycle is reset to zero and relay SE energizes.

If the normal source voltage does not return above the

sensor dropout setting before the time delay expires, the

NR relay de-energizes and signals the engine-driven

generator to start. At the same time, a voltage and

frequency sensor begins monitoring the emergency

source. The sensor will accept the emergency source only

when both voltage and frequency reach preset pickup

points. Usually about ten seconds elapse from dropout of

the NR relay to acceptance by the sensor. This time span

occurs because the engine-driven generator must crank,

start, and run up to nominal pickup points. For this

reason, if the Transfer Test buttonispresseditmustbe

held for 15 seconds. If the emergency source is available

immediately, the sensor may accept it as soon as NR relay

drops out.

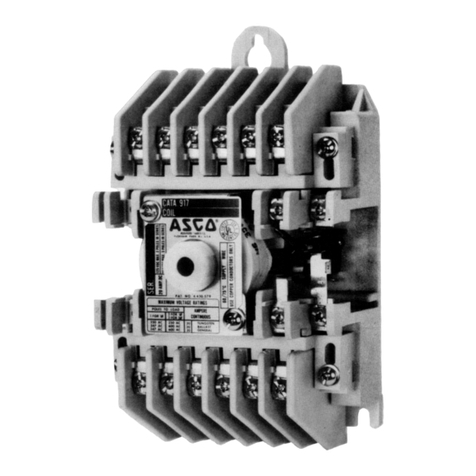

When the emergency source is accepted by the sensor,

relay ER begins its timing cycle (transfer to emergency

delay). ER relay is provided with an adjustable (0 to 5

minutes) time delay on pickup to delay transfer of the

load to the emergency source. For immediate transfer

press Bypass Time Delay button.

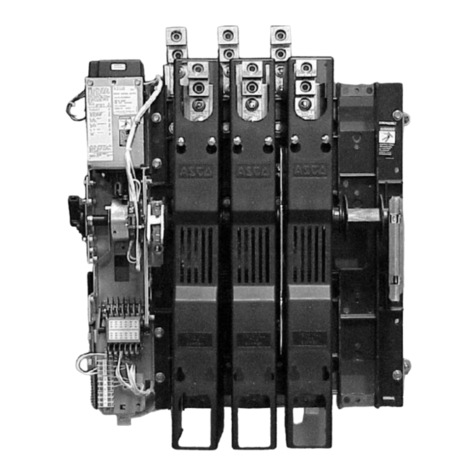

ER relay energizes, the TS coil is energized, the

transfer switching device operates, and all switch

contacts (mains, controls, auxiliaries) reverse position.

The transfer switch is now supplying the load from the

emergency source.

The transfer switching device will remain in the

Emergency position until the normalsource is restored.

If the Transfer Test button is used, the transfer switching

device will remain on emergency until the retransfer to

normal delay times out.

Retransfer to Normal

The sequence for load retransfer to the normal source

automatically begins when the voltage sensor detects

restoration of the normal source. The voltage level

must rise above the preset pickup point on all phases

before the sensor will accept the normal source.

When the normal source is accepted by the sensor,

relay SE begins its timing cycle (adjustable 1 sec. to 30

min., retransfer to normal delay). For immediate

retransfer press Bypass Time Delay button. SE relay is

provided with a time delay on pickup to prevent

immediate load retransfer to the normal source. The

delay insures that the normal source has stabilized

before reconnection of vital loads. If the normal source

voltage falls below the present dropout point before the

time delay expires, the timing cycle is reset to zero. If

the emergency source fails for more than 4 seconds

during the timing cycle, ER relay drops out and the load

is immediately retransferred to the normal source, if

that source is acceptable.

SE relay energizes and ER relay is dropped out. The TS

coil is energized, the transfer switching device oper-

ates, and all switch contacts (mains, controls, auxilia-

ries) reverse position. The transfer switching device is

now supplying the load from the normal source again.

Upon retransfer to the normal source, NR relay begins

its timing cycle (unloaded running delay [engine cool-

down] ). NR relay is provided with a 5 minute time

delay on pickup to keep the engine running for a

cool-down period.

NR relay energizes after the time delay and signals the

engine-driven generator to shut down. All circuits are

reset for any future normal source failure.

Activation of standard control features shown in Section

5 will alter the sequence of operation and introduce

additional time delays during transfer operations.

Get other manuals https://www.bkmanuals.com