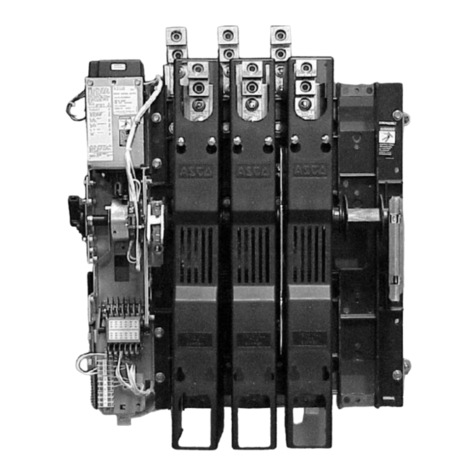

Series 4000 Automatic Transfer Switch Operator’s Manual

Page 10 ASCO Power Technologies 381333-270D

Testing & Service

TRANSFER TEST

Operate the 4000 Series ATS at least once a month by

following the five–step Electrical Operation Transfer

Test procedure on page 9.

PREVENTIVE MAINTENANCE

Reasonable care in preventive maintenance will insure

high reliability and long life for the 4000 Series ATS. An

annual preventive maintenance program is recommended

ASCO Power Services, Inc. is ASCO Power Technologies

service organization for the United States and Canada.

Call 1-800-800-2726 (ASCO) to request a service call and

information on preventive maintenance agreements.

Annual Inspection Checklist

Hazardous voltage capable of causing

shock, burns, or death is used in this switch.

Deenergize both Normal & Emergency power

sources before performing inspections!

□Clean the ATS enclosure. Brush and vacuum away

any excessive dust accumulation. Remove moisture

with a clean cloth.

□Check the transfer switch contacts. Remove the

transfer switch barriers and check contact condition.

Replace the contacts if they become pitted or worn

excessively. Reinstall the barriers carefully

□Maintain transfer switch lubrication. If the transfer

switch is subjected to severe dust or abnormal

operating conditions, renew factory lubrication on

all movements and linkages. Relubricate the

solenoid operator if the TS coil is replaced. Do not

use oil; order lubrication 625550–001 (Castrol

Endurex R4000 lubricant) for 30–230 amp., or order

lubrication kit 75-100 for 260–4000 amp. sizes.

□Check all cable connections & retighten them.

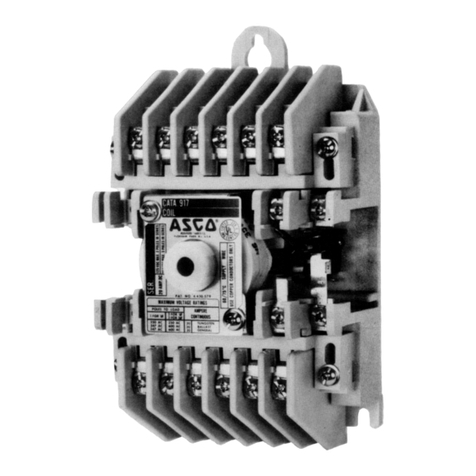

REPLACEMENT PARTS

Replacement parts are available in kit form. When ordering

parts provide the Serial No., Bill of Material No. (BOM), and

Catalog No. from the transfer switch nameplate. Contact your

local ASCO Power Technologies Sales Office or ASCO Power

Services, Inc.

In the United States and Canada

call 1 – 800 – 800 – ASCO (2726)

DISCONNECTING THE CONTROLLER

The harness disconnect plugs are furnished for repair

purposes only and should not have to be unplugged. If the

controller must be isolated, follow these steps.

Disconnecting the Plugs

Do not unplug the controller

until steps 1a or 1b is completed.

1.Observe the position of the transfer switch.

a. If the transfer switch is in the Normal position, first

place standby engine starting control in the off

position. Second, then open the emergency source

circuit breaker. Third, open the normal source circuit

breaker.

b.If the transfer switch is in the Emergency position, first

open the normal source circuit breaker. Second, place

the engine starting control in the test or run position.

Third, open the emergency source circuit breaker.

2. Separate the two quick disconnect plugs by squeezing

the latches. Do not pull on the harness wires.

Reconnecting the Plugs

Do not unplug the controller

until steps 1a or 1b is completed.

1. Observe the position of the transfer switch.

a. If the transfer switch is in the Normal position, first

be sure that both normal and emergency source

circuit breakers are open. Second, be sure that the

standby engine starting control is still in the off

position.

b. If the transfer switch is in the Emergency position,

first be sure that both normal and emergency source

circuit breakers are open.

2. The two harness plugs and sockets are keyed. Carefully

align the plugs with the sockets and press straight in

until both latches click. Close the door!

3. Restore the two sources in sequence as follows:

a. If the transfer switch is in the Normal position, first

close the normal source circuit breaker. Second, close

the emergency source circuit breaker. Third, place

the standby engine starting control in the automatic

position.

b. If the transfer switch is in the Emergency position,

first close the emergency source circuit breaker.

Second close the normal source circuit breaker.