Page 3 of 8 (Section 1 of 2)

I&M No.V7544-Sec.1

50 Hanover Road, Florham Park, Ne Jersey 07932 .ascovalve.com

WARNIN : To prevent the possibility of death,

personal injury or property damage, check valve

for proper operation before returning to service.

Also perform internal seat and external leakage

tests with a nonhazardous, noncombustible fluid.

12. Restore auxiliary and main line pressure to valve.

Valve Disassembly for 3/4I or 1I NPT Valves

1. Disassemble valve in an orderly fashion usin exploded view for

identification and placement of parts.

2. A 4-40 machine screw provided in ASCO Rebuild Kit serves as a

self-tappin screw to remove insert from body. Thread screw a few

turns into throu h hole located in flat surface of the insert.

C UTION: Do not damage center hole (pilot orifice) in

raised surface of insert.

3. Remove insert by usin a pair of pliers to rip the head of the screw.

Then pull insert with askets from body insert cavity.

4. Remove three askets from insert. Ta each as they are removed so

that they can be reassembled in the same location. Middle and lower

askets are the same size, however, the lower asket is a softer material.

Then remove disc holder sub-assembly and disc holder sprin .

5. Remove lon body screws with lockwashers (4) from piston end body.

Slip piston end body off piston/shaft sub-assembly.

6. Remove small body askets (2) from counterbores in piston end body.

7. Slide piston/shaft sub-assembly from main valve body. The

piston/shaft sub-assembly is comprised of the main shaft, shaft nut,

shaft washer, piston, body u-cup, uide u-cup, shaft asket, piston

uide, seat asket, uide askets (2) and a resilient main disc.

8. Disassemble piston/shaft assembly by insertin a brass rod (of suitable

size) into cross hole in shaft. Rod must be brass or made of another

soft material, so as not to burr ed es of hole. Hold piston shaft firmly

(with rod) and unscrew shaft nut.

9. Disassemble piston/shaft sub-assembly in an orderly fashion. Be

careful not to dama e or mar any of the parts.

10. Remove shaft nut, shaft washer, piston with body and uide-u-cups

(2) attached from shaft. Then remove body u-cup and uide u-cup

from piston.

11. Remove shaft asket, piston uide, uide askets (2) seat asket, and

resilient main disc.

12. Remove short body screws with lockwashers (4) from opposite end of

main valve body. Remove body/seat asket and seat asket from seat.

Then remove the other resilient main disc from bore of main valve

body.

13. All parts are now accessible to clean or replace. If parts are worn or

dama ed install a complete ASCO Rebuild Kit.

Valve Reassembly for 3/4I or 1I NPT Valves

1. Lubricate body/seat asket, seat asket, upper, middle and lower insert

askets with DOW CORNINGr 200 Fluid lubricant or an equivalent

hi h- rade silicone fluid lubricant.

2. Lubricate all remainin askets, u-cups, bores of piston, piston end

body, main disc slidin area on the main shaft and valve body insert

cavity (see Fi ure 3) with a li ht coat with DOW CORNINGr 111

Compound lubricant.

3. Preassemble piston/shaft sub-assembly as follows:

A. Position resilient main disc on shaft so that resilient lip side of

disc is facin the piston uide.

B. Install seat asket and uide askets (2) on piston uide.

C. Slip piston uide with askets onto shaft.

D. Position shaft asket on shaft.

E. Install uide u-cup and body u-cup on piston. Make certain

that open end of uide u-cup faces, the main valve body, while

open end of body u-cup faces the piston end body. Position the

piston with u-cups on shaft.

F. Replace shaft washer and shaft nut. Torque the shaft nut to 125

± 10 in-lbs [14,1 ± 1,1 Nm] while holdin the shaft as described

in Valve Disassembly for 3/4I or 1I NPT valves section step 9.

4. Install piston/shaft sub-assembly in main valve body.

5. Position small body askets (2) in counterbores in piston end body.

6. Slip piston end body over the piston/shaft sub-assembly. Then install

lon body screws with lockwashers (4). Torque the lon body screws in

a crisscross manner to 40 ± 5 in-lbs [4,5 ± 0,6 Nm].

7. Install resilient main disc at opposite end of main shaft. Be sure

resilient side of disc is facin seat.

8. Position seat asket and body/seat asket on seat.

9. Install seat with askets into main valve body. Replace short body

screws with lockwashers (4). Torque body screws in a crisscross

manner to 40 ± 5 in-lbs [4,5 ± 0,6 Nm].

10. Position lower insert asket and disc holder sprin in body insert cavity.

11. Snap upper and middle insert askets into rooves of insert. Lower

insert asket fits into the recess between the lower corner of the insert

and the lower corner of the body insert cavity. Middle and lower insert

askets are the same size. However, the lower asket is made of a softer

material.

12. Place disc holder sub-assembly into insert. Install insert (with askets

and disc holder assembly) into body insert cavity, makin certain that

the disc holder sprin is centered. Rotate this assembly sli htly while

pushin downward to aid installation.

WARNIN : To prevent the possibility of death,

personal injury or property damage, check valve

for proper operation before returning to service.

Also perform internal seat and external leakage

tests with a nonhazardous, noncombustible fluid.

13. Restore auxiliary and main line pressure to valve.

Disassembly of Manual Operator

1. Unscrew solenoid base sub-assembly from manual operator body.

2. Unscrew manual operator body from valve body. Then remove stem

retainer from base of manual operator body and stem/spacer

sub-assembly.

3. Pull stem/spacer sub-assembly with stem asket from side of manual

operator body. Then remove core assembly with core sprin , solenoid

base asket and manual operator bonnet asket.

4. For further disassembly refer to section on Valve Disassembly step 4.

Reassembly of Manual Operator

1. Lubricate manual operator stem asket with DOW CORNINGr 111

Compound lubricant or an equivalent hi h- rade silicone rease.

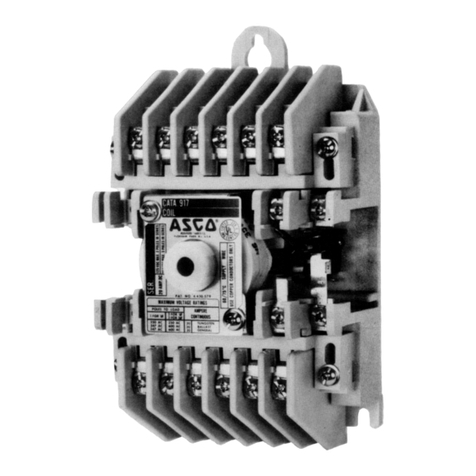

2. For AC/DC construction (Fi ure 2A), install core assembly with sprin

and core uide..

3. Holdin the manual operator body in a vertical position, install core

assembly with core sprin from the bottom end.

4. Insert the stem/spacer sub-assembly with the stem asket into the side

hole of the manual operator body. Rotate the lever of the stem/spacer

sub-assembly to the 12 o'clock position.

5. Install stem retainer on base of manual operator body and

simultaneously en a e it into the slot provided on the stem/spacer

sub-assembly.

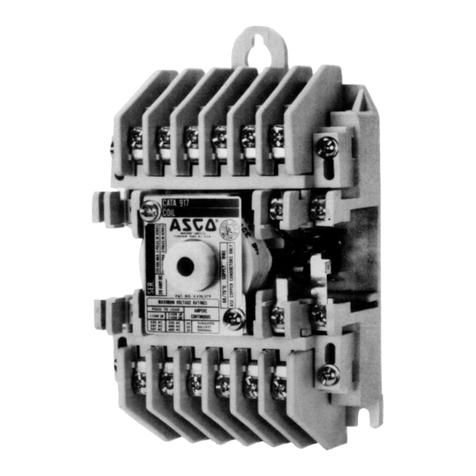

IMPORT NT: The spacer on the stem/spacer sub-assembly must

be outside of the stem retainer for C/DC construction (Figure 2B).