GE SE-100E User manual

Other GE Switch manuals

GE

GE MultiLink ML1200 User manual

GE

GE Cync CSWONBLBWF1NN User manual

GE

GE MultiLink ML810 User manual

GE

GE Manual Service Bypass User manual

GE

GE 97845 User manual

GE

GE "ExecutiveSeries"USB2.0 HO97863 User manual

GE

GE HO98751 User manual

GE

GE Z-wave User manual

GE

GE 50 AMP AUTOMATIC TRANSFER SWITCH Setup guide

GE

GE Digital Energy STS-400-25-3 User manual

GE

GE GEH-4763 User manual

GE

GE Motion Sensing Diecast Metal Lantern None User manual

GE

GE Cync User manual

GE

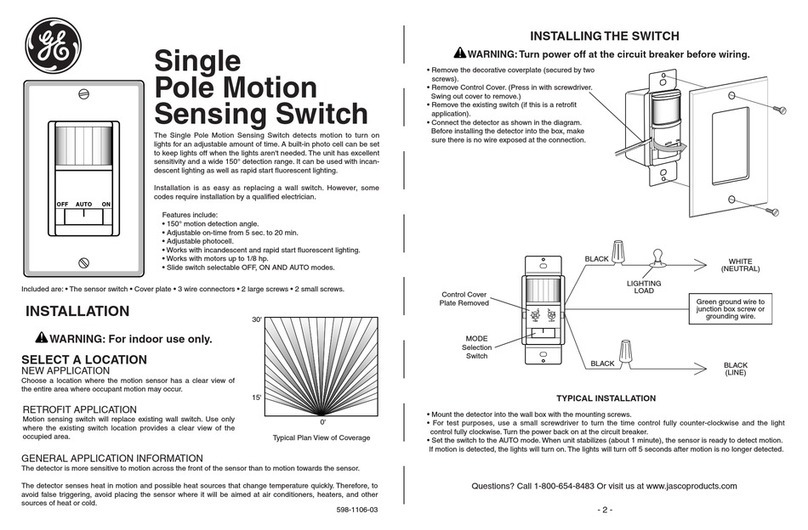

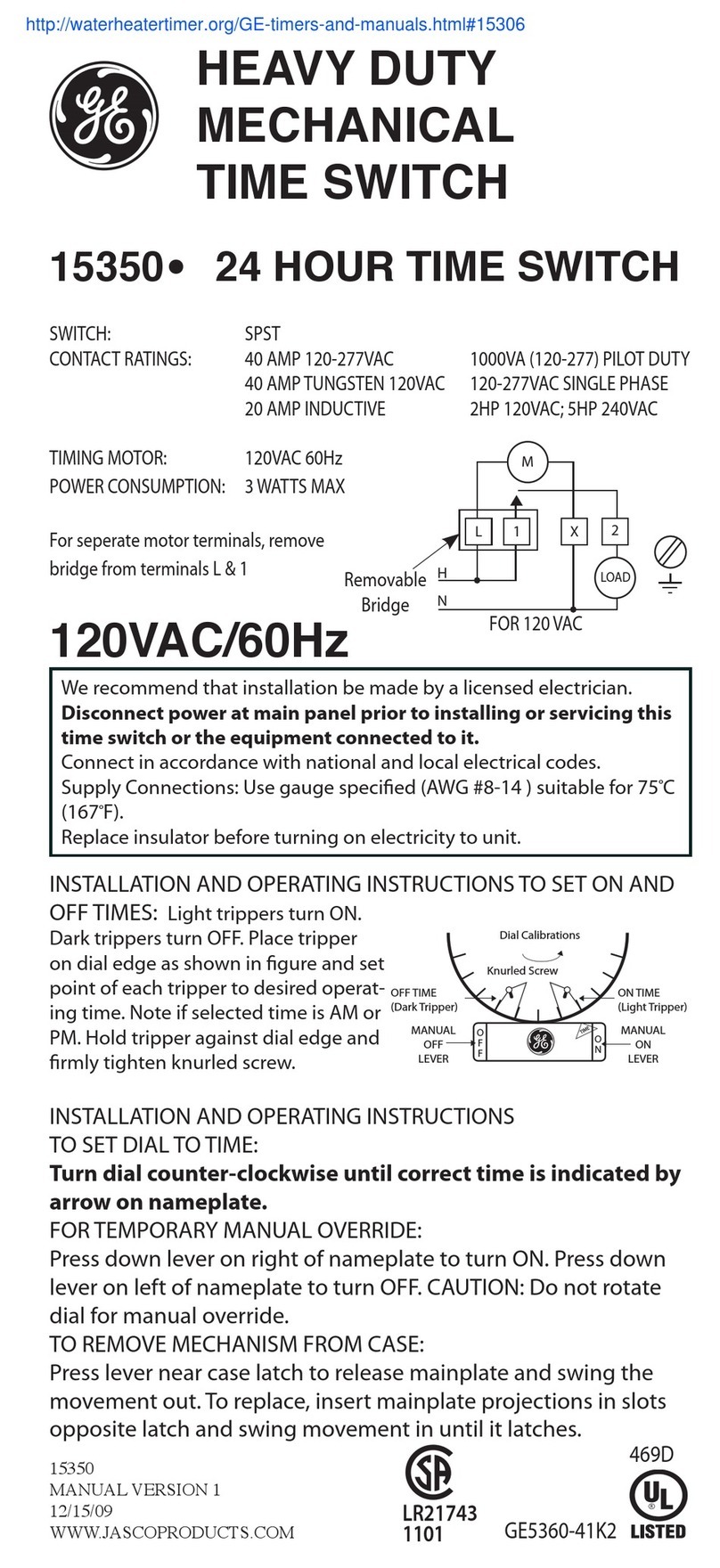

GE 15350 User manual

GE

GE MULTILINK ML2400 User manual

GE

GE C-Start User manual

GE

GE GuardSwitch 300 Series User manual

GE

GE POWERMASTER AKD-5 User manual

GE

GE ABB ReliaGear LV SG User manual

GE

GE ZW4106 User manual