INSTALLATION Series 911

1381333–241

ASCO Series 911 Remote Control (RC) Switches are

all–purpose single–throw switches available in capacities

from 100 to 1200 amps. They can be used for all classes

of loads to 480 volts ac to their full ratings, open or

enclosed. Loads may be 100% tungsten rated at 250 volts

ac. Inrush or stalled–rotor motor currents do not affect

the switch rating. Thermal capacity is 20 times full load

rating.

Series 911 RC Switches are ideally suited for use as panic

switch control, where transformer type dimmers are used.

They are capable of withstanding high fault currents until

the overcurrent protective device operates. Series 911

RC Switches can interrupt 600% of rated current at 480

volts, 60 Hz, 0.4 to 0.5 power factor; thus all Series 911

RC Switches may be used for switching ac motor circuits.

Inspection

Inspect packaging carefully for shipping damage. If any

damage is discovered, leave the packing material as is

and immediately file a claim with the shipper. After the

carrier has inspected the damage contact your local

ASCO Power Technologies source for assistance.

Unpacking

When you are ready to install the switch, carefully

unpack or uncrate it. Protect the switch at all times from

moisture, construction grit, and metal chips.

Handling

Handle the RC Switches by grasping the back panel. Do

not lift the RC Switch at any other points. Protect the

arc barriers at all times from impact.

Nameplate / Rating Label

The Series 911 RC Switch contains a nameplate / rating

label which includes data for that specific RC Switch. It

defines the loads and fault current withstand/closing

ratings. Refer to the label on the RC Switch for specific

values and use the RC Switch only within their limits.

Do not exceed the values on the nameplate /

rating label. Exceeding the rating can cause

personal injury or serious equipment damage.

Mounting

Two Composite Outline drawings are furnished in the

back of this manual. Use drawing 405386 for 100–400

amp size open–type RC Switches, or use drawing 405387

for 600–1200 amp size open–type RC Switches. Use

drawing 405388 for enclosed RC Switches. The diagrams

show all mounting details and instructions.

To prevent malfunction or shortened

life for the RC Switch protect it from

construction grit and metal chips.

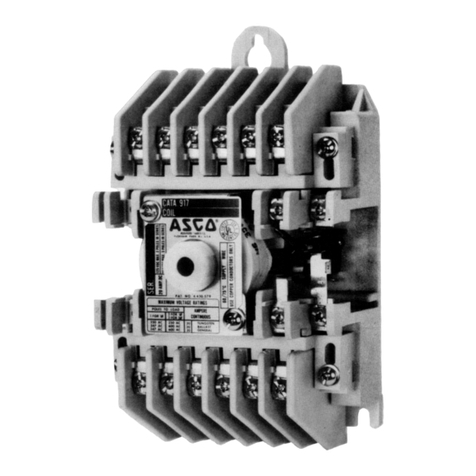

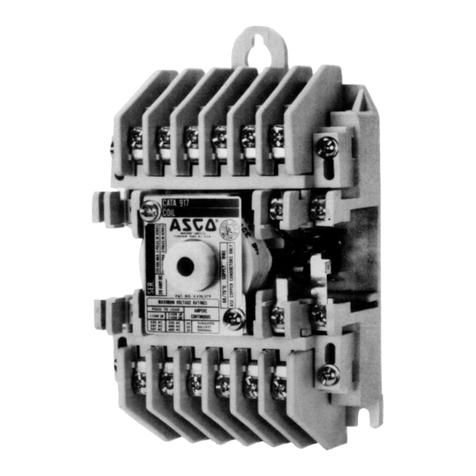

RC Switches rated 100–225 amperes must be mounted on

supplied insulator bushings and backing insulators

(installed behind the switch). Likewise, mount open–

type 260 and 400 ampere RC Switches on supplied

insulator backing piece. If the switch is removed from

the enclosure and then reinstalled, these insulator

bushings and backing insulators must be placed behind

the RC switch. See Figures 1 and 2.

Be sure that the insulator pieces are behind the

100, 150, 200, and 225 ampere RC Switches.

Also be sure to use the insulator bushings under

the hardware.

Figure 1. Required insulator bushings and backing

insulators for 100–225 amp. RC Switches.