2

Information

cc

NOTES

ON ELECTRIC

SAFETY AND

ELECTROMAGNETIC

COMPATIBILITY

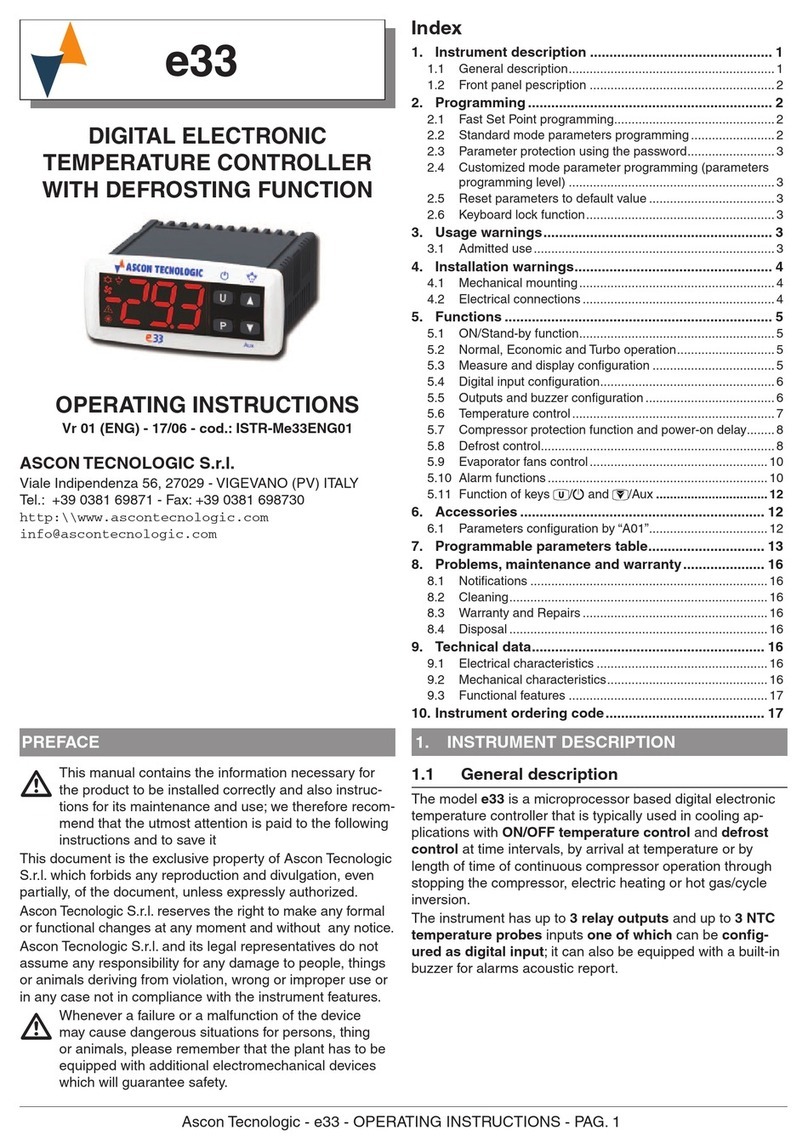

Please, read carefully these instructions before proceeding with

the installation of the controller.

Class II instrument, for indoor use only.

This controller has been designed with compliance to:

Regulations on electrical apparatus (appliance, systems and installa-

tions) according to the European Community directive 73/23/EEC amend-

ed by the European Comunity directive 93/68/EEC and the Regulations

on the essential protection requirements in electrical apparatus EN61010-

1 : 93 + A2 : 95.

Regulations on Electromagnetic Compatibility according to the

European Community directive n° 89/336/EEC, amended by the European

Community directive n° 92/31/EEC, 93/68/EEC, 98/13/EEC

and the following regulations:

- Regulations on RF emissions:

EN61000-6-3: 2001 residential environments

EN61000-6-4: 2001 industrial environments

- Regulation on RF immunity:

EN61000-6-2: 2001 industrial equipment and system

It is important to understand that it’s responsibility of the installer to ensure

the compliance of the regulations on safety requirements and EMC.

Reapirs: this device has no user serviceable parts and requires special

equipment and specialised engineers. Therefore, a repair can be hardly

carried on directly by the user. For this purpose, the manufacturer pro-

vides technical assistance and the repair service for its Customers.

Please, contact your nearest Agent for further information.

All the information and warnings about safety and electromagnetic

compatibility are marked with the Bsign, at the side of the note.