Table of Contents

Quick Start ...........................................................................................................................5

Hardware Needed............................................................................................................................................5

Information Needed ........................................................................................................................................5

Physiclly Install TeleBoss..............................................................................................................................5

Power Requirements & Options....................................................................................................................6

Power Up Sequence .....................................................................................................................................9

Accessing the TeleBoss.................................................................................................................................9

Access via a Network Connection.................................................................................................................9

Default Passwords ..................................................................................................................................... 10

Access via a Serial Connection.................................................................................................................. 11

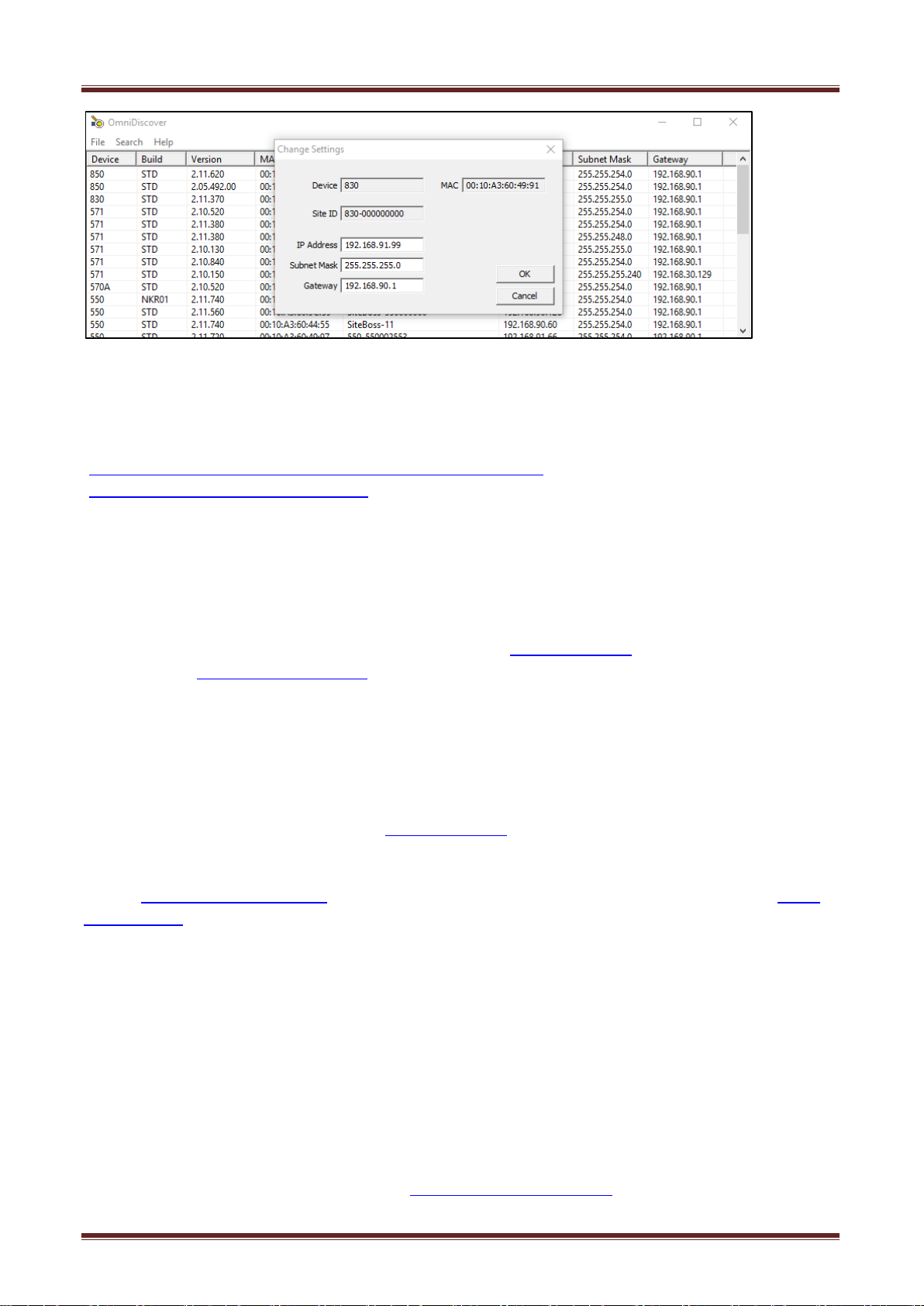

Configuring Ethernet Settings via IO2........................................................................................................ 12

Testing Network Connectivity..................................................................................................................... 13

What is a TeleBoss 830.....................................................................................................14

The Basics .................................................................................................................................................... 14

Communication Methods............................................................................................................................ 15

Data Storage .............................................................................................................................................. 15

Serial Monitoring (Data Events) ................................................................................................................. 16

Environmental Monitoring........................................................................................................................... 16

Features and Accessories .......................................................................................................................... 16

Standard Equipment................................................................................................................................... 16

LEDs, Ports, DIP Switches and Buttons .................................................................................................... 17

Optional Hardware ..................................................................................................................................... 21

Navigating the Control Interfaces ....................................................................................24

Command Line Interface (CLI).................................................................................................................... 24

CLI Status Pages ....................................................................................................................................... 24

Setup Menu Inputs ..................................................................................................................................... 28

Web Interface (GUI)...................................................................................................................................... 30

Web Interface Status Pages....................................................................................................................... 31

Web Interface Control Features................................................................................................................. 33

Setup Menu........................................................................................................................36

Network Settings.......................................................................................................................................... 37

Ethernet Settings........................................................................................................................................ 40

Name Resolution Settings.......................................................................................................................... 42

IP Record Collection Settings..................................................................................................................... 42

Web Interface Settings............................................................................................................................... 58

EventSensor Reporting Settings................................................................................................................ 59

SNMP Settings........................................................................................................................................... 60

FTP Settings............................................................................................................................................... 61

PPP Settings .............................................................................................................................................. 63

Email Settings............................................................................................................................................. 67

Real-Time Socket Settings......................................................................................................................... 68

Routing....................................................................................................................................................... 69

DSL Settings............................................................................................................................................... 71

VPN Settings.............................................................................................................................................. 71

CPE Settings.............................................................................................................................................. 74

Ethernet Expansion Settings...................................................................................................................... 76

Serial Settings .............................................................................................................................................. 78

Modem Settings ........................................................................................................................................... 82

Dialup Modem ............................................................................................................................................ 82

Wireless Modem......................................................................................................................................... 84

Security Settings.......................................................................................................................................... 87

User Profile Security Settings..................................................................................................................... 87

General Security Settings........................................................................................................................... 93

SSL Certificate via Web Interface .............................................................................................................. 94

Alarm / Event Definitions ............................................................................................................................ 97