4

Operating Instructions and Parts Manual

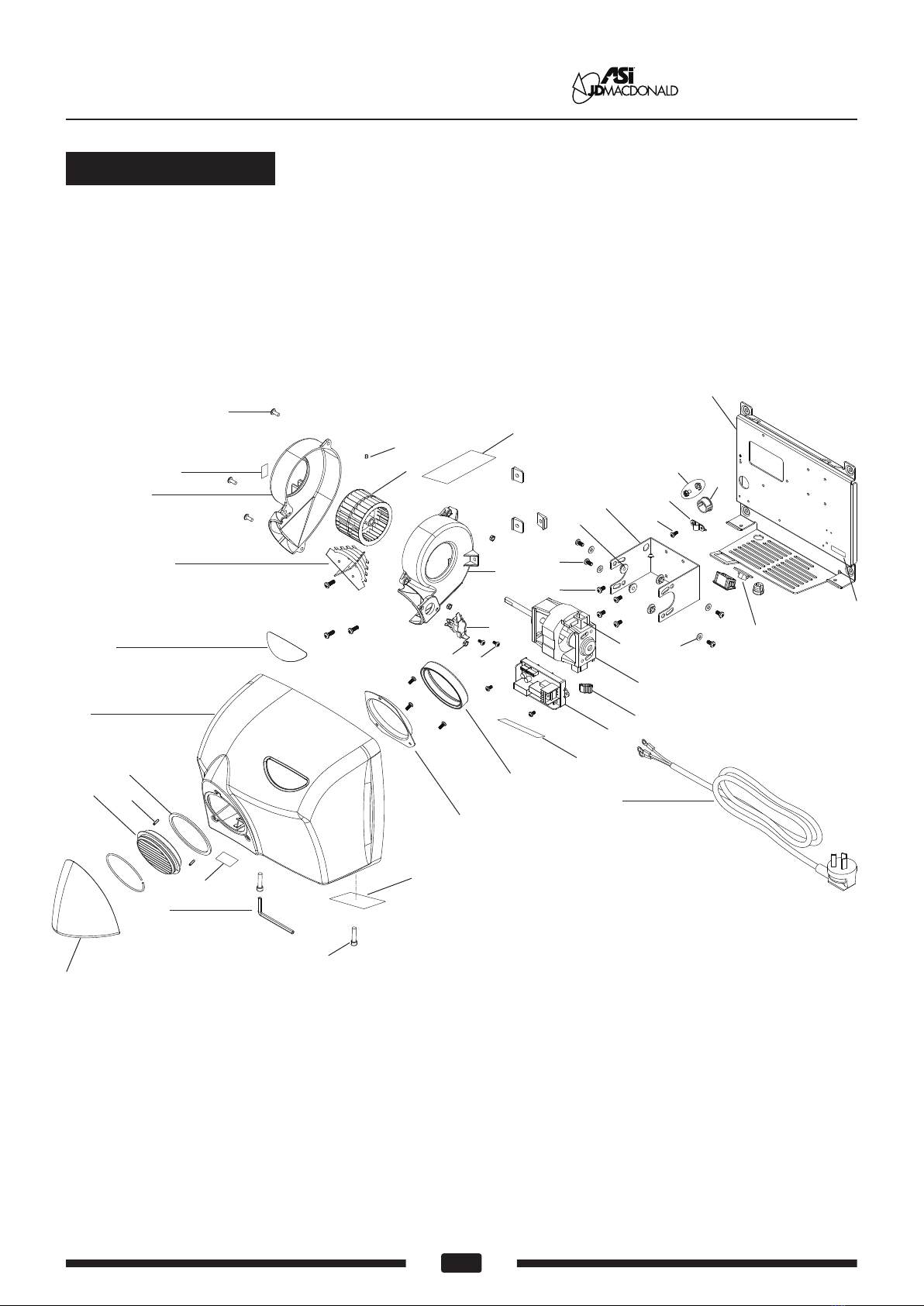

Hand Dryer

Symptom Corrective Action

Troubleshooting

If the dryer will not run First ensure that the breaker supplying the dryer is operational.

If it is, disconnect the power and remove the dryer cover.

Check for obstructions blocking the rotation of the blower and

clear any found. If it spins freely, check the motor and

thermostat for proper operation out of the unit. Replace any

failed items. Taking suitable precautions to avoid shock hazard,

reconnect the power and check for voltage at the terminal

block. If there is power and the dryer will not run, replace the

timer assembly and/or sensor module.

If the dryer cycles by itself, or runs

all the time, or shuts off by itself

while in mid-cycle

If the element gets hot but the fan

motor does not turn

Disconnect the power. Remove the dryer cover and check for

obstructions in the fan housing. Damaged fans must be

replaced. If there are no obstructions, replace the motor.

If the fan motor runs but the element

does not get hot (Dryer blows cold air)

Disconnect the power and remove the dryer cover. Check for

loose or damaged wires. Remove the blower housing.

Check the element for signs of burning or breakage. Damaged

element must be replaced. If the element does not appear

damaged, disconnect it at the timer assembly and check

element wire continuity (see tech spec). An open circuit

indicates damage to the element wire and to the integral

temperature limit control (TLC). Separate the TLC and test for

open circuit. If this is the case, replace the element and/or the

thermostat.

If the motor makes ticking/winding

noise when it runs

If the unit runs but makes a

buzz noise

Disconnect the power. Remove the dryer cover and check the

fan for obstructions and/or rubbing on the housing as it

rotates. Remove any obstructions and replace fan if the

rubbing condition exists.

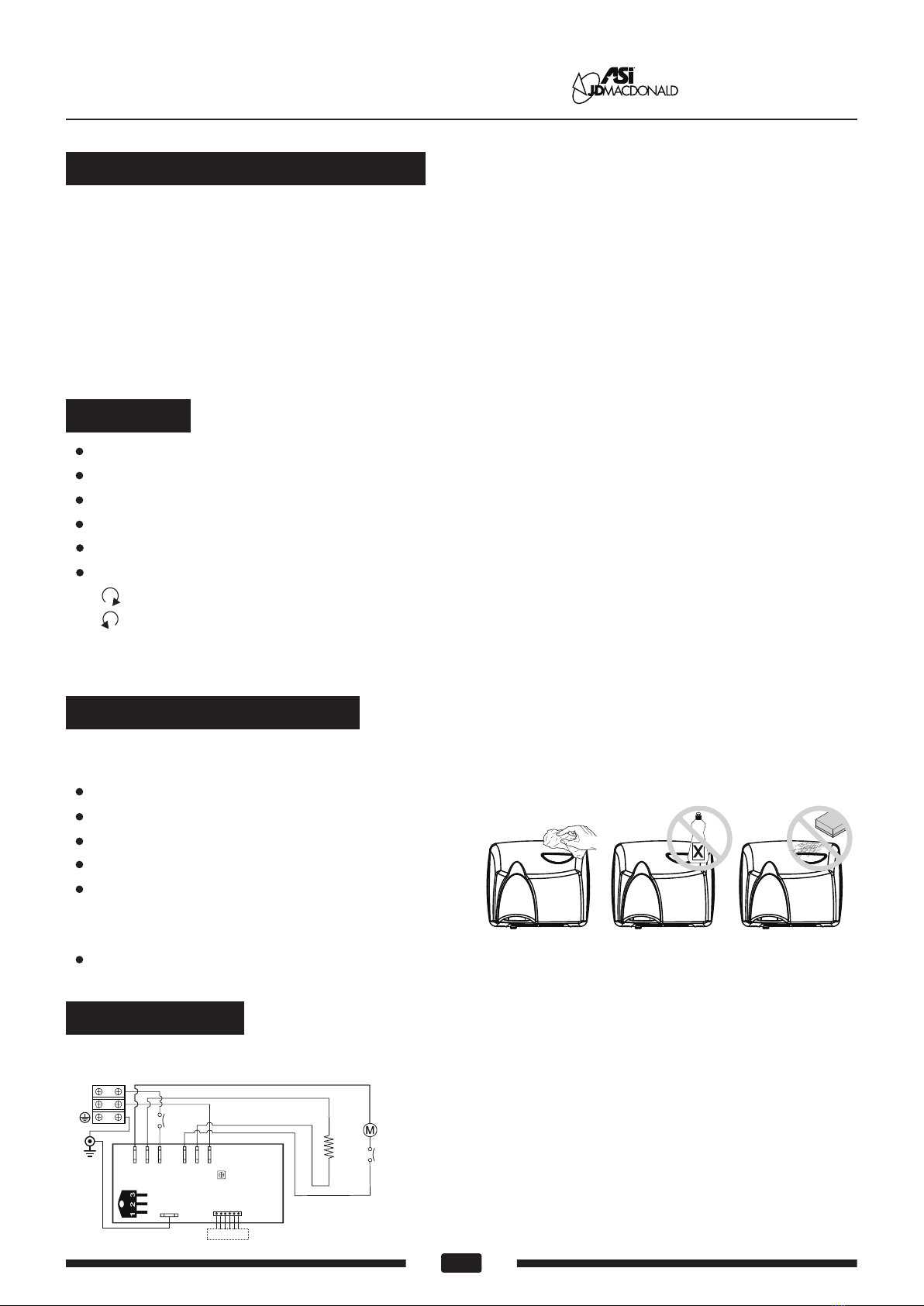

Ensure that there is no obstruction on or in front of the

infrared sensor. Clean any dirt off the sensor lens. Check for

voltage spikes on power line. If the problem persists, replace

the timer assembly and/or the sensor module.

Disconnect the power. Remove the dryer cover and check the

brushes for worn condition (less than 25/64" (10mm) graphite

remains) and replace them, if necessary. Purchase rebuild

kit to perform repair.

Surface-mounted Automatic hand dryer www.asijdmacdonald.com.au

1800 023 441

www.asijdmacdonald.com.au

ASI J D MacD onal d Pty. Ltd.