2

Operating Instructions and Parts Manual

Hand Dryer

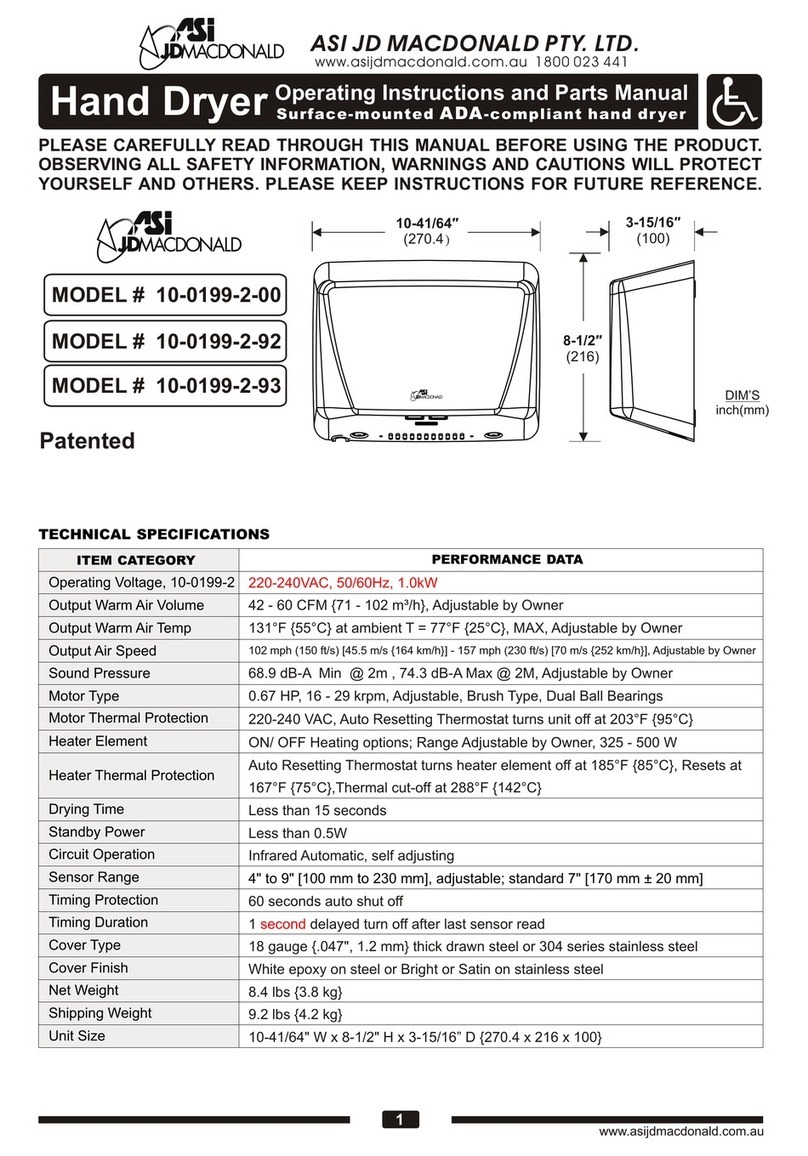

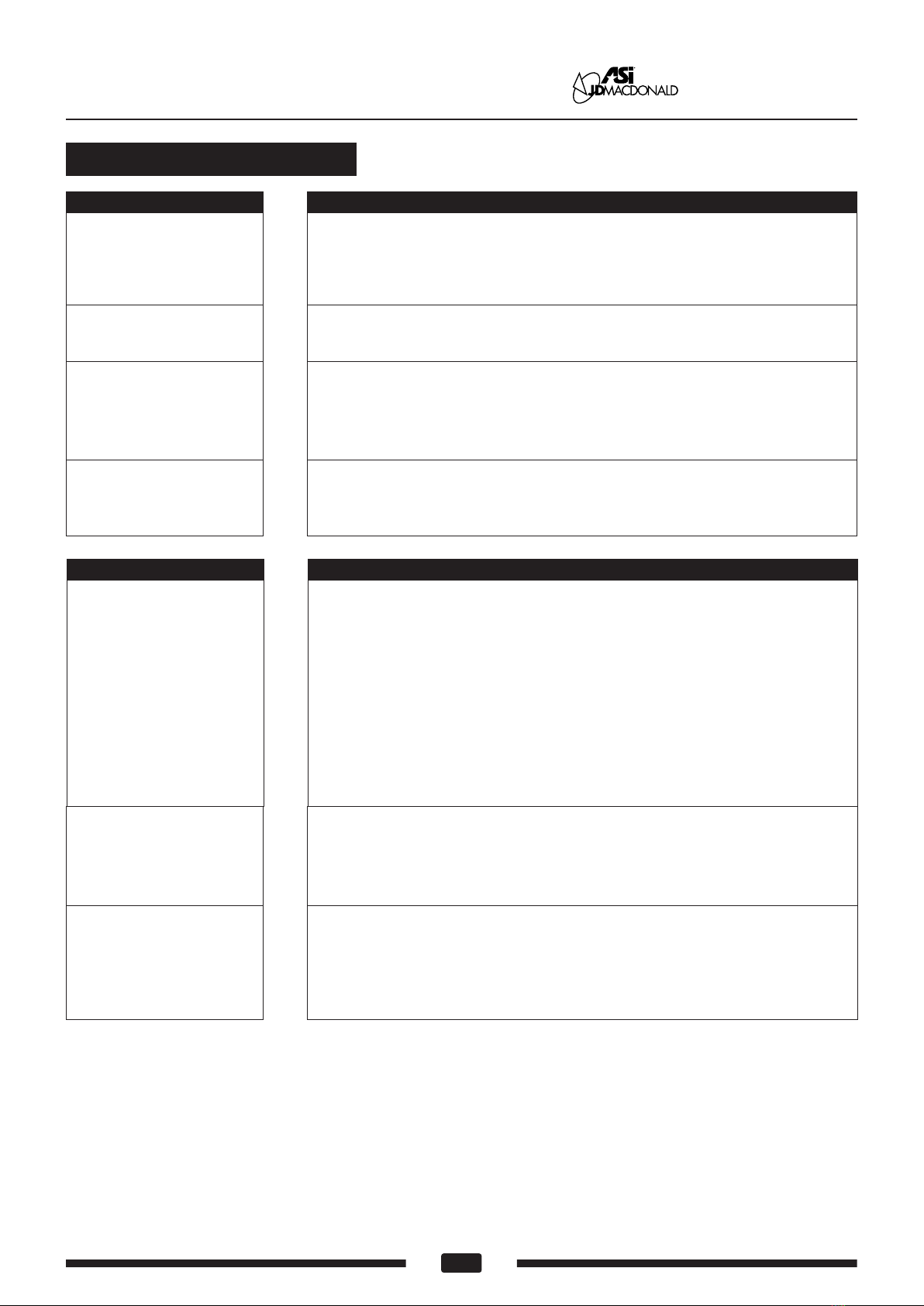

Motor Heater TotalModelInput

Recessed High-Speed ADA-compliant hand dryer

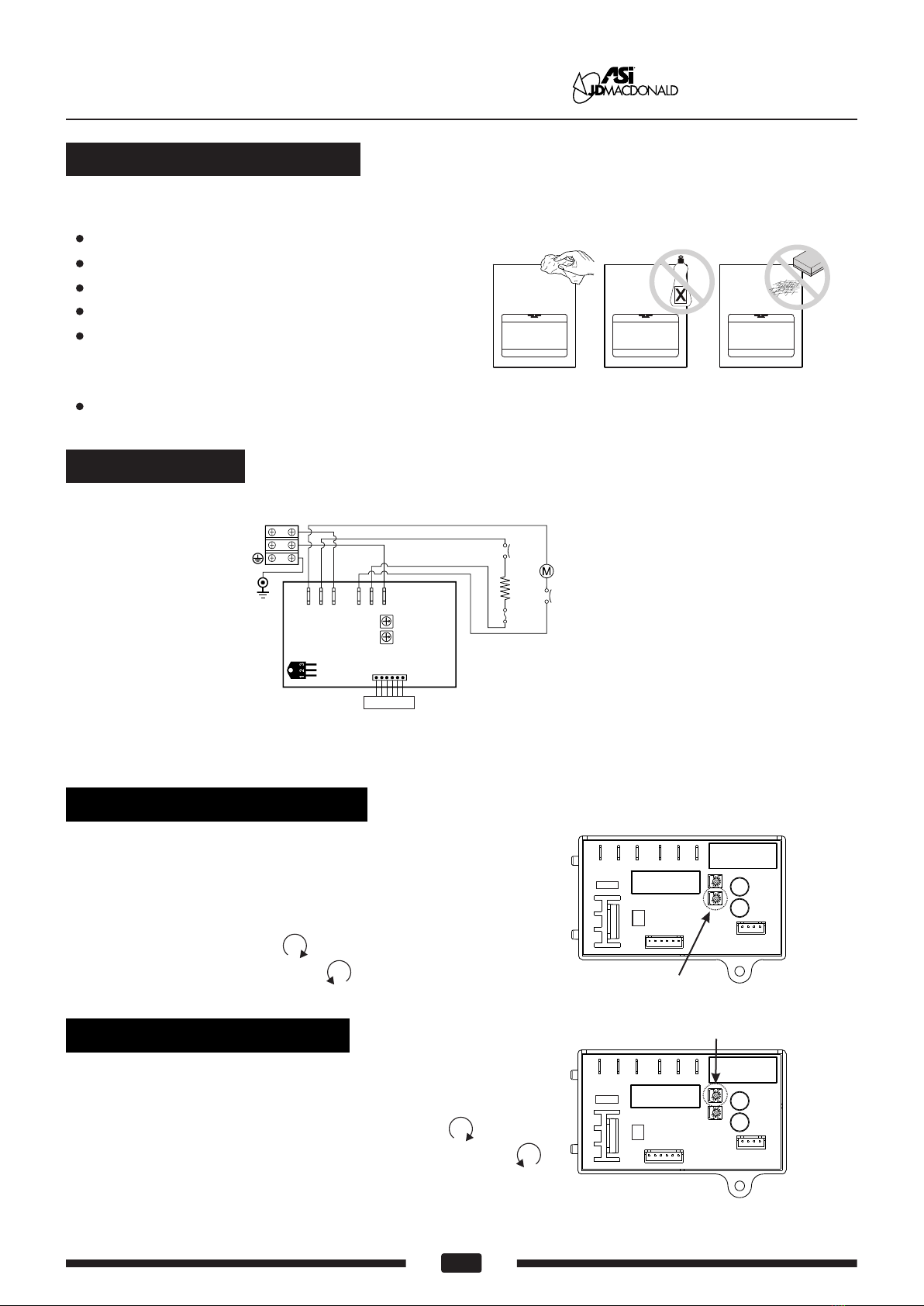

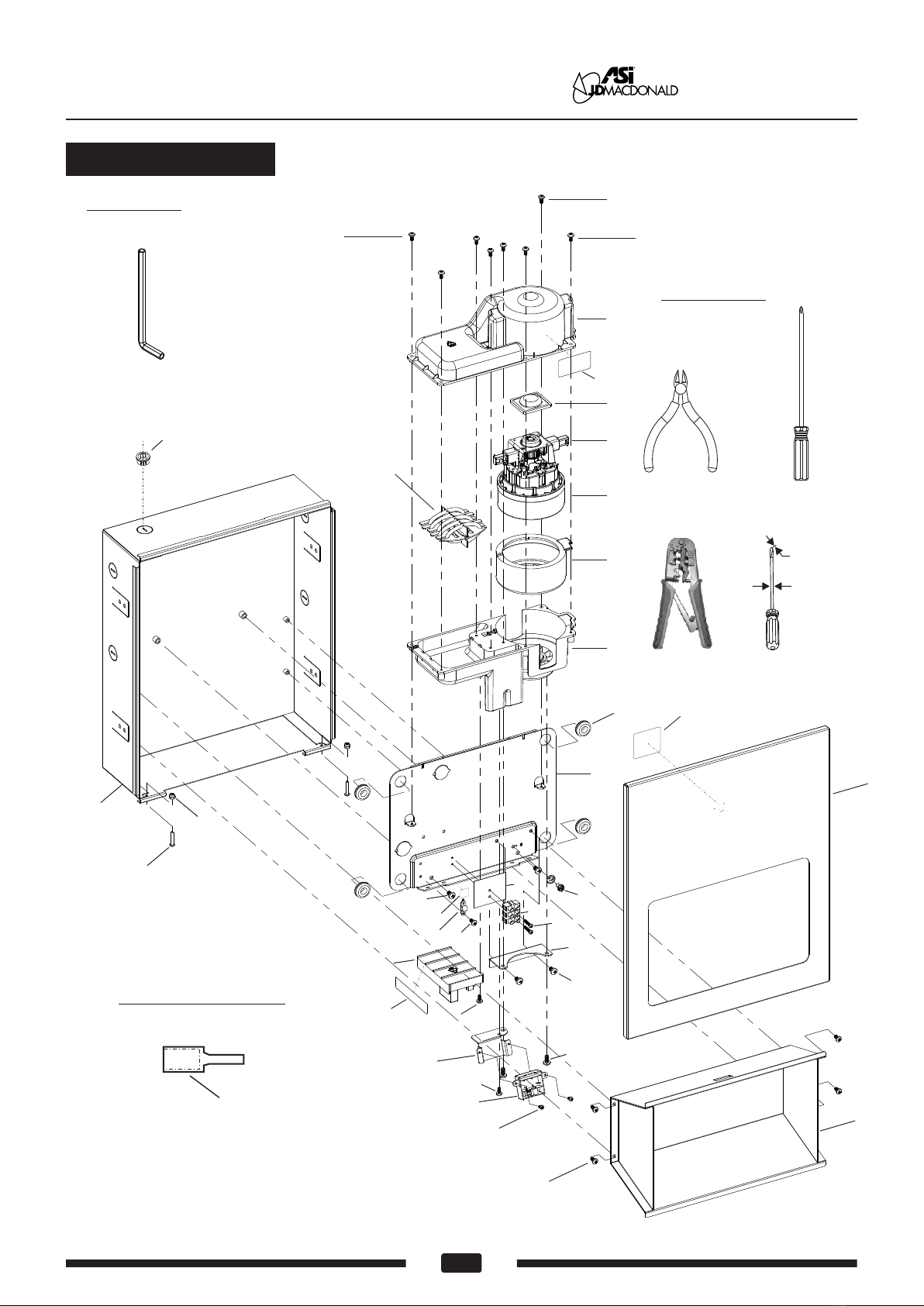

Installation

2. Remove front panel using security wrench included in kit and retain security screws. Place cover aside with

care to protect face finish until required in step 8.

3. Remove hand drying chamber using #2 PhilIips screwdriver and retain screws. Place chamber aside with

care to protect inside finish until required in step 7.

4. Remove two (2) mounting screws from bottom edge of chassis plate using #2 PhilIips screwdriver and retain

screws. Grasp motor securely and lift entire chassis slightly up & over retainer hooks welded to housing

top. Place chassis aside with care to protect unit until required in step 5.

5. Install supplied plastic KO bushing (or other, not supplied) into KO to be used for cable prior to installation

of cable into KO or box into RWO (Rough Wall Opening, previously prepared by others). Install wall box

housing into RWO locating stub cable into any one (1) of five (5) available KO locations on sides or top

of box. Using screws supplied with unit (or other types suitable to wall conditions, by others) tighten screws

through adjustable mounting tabs into framing in side walls of RWO to center wall box in opening.

6. Grasp chassis & motor assembly retained in step 3 and slightly lift to place over retainer hooks on housing

top to hold unit in place while driving screws. Using #2 PhilIips screwdriver tighten two (2) screws also

retained in step 3 through holes in bottom edge of chassis plate into threaded posts on wall box back.

7. Refer to Circuit Diagram on page 4 of this Owner's Manual to match correct wire to terminal block on motor

chassis. Pull stub cable through bushing (previously installed, step 4) to allow clearance around hand drying

chamber (to be installed next) and enough length to prep ends for terminal block insertion after routing through

strain relief clamp on chassis. Clamp cable, prep ends of wires and insert correct wires into terminal block

at locations L, N & G. Using a small flat blade screwdriver ensure each wire is properly secured with terminal

block top lock screws.

Connections: (see fig. 6 & refer to Circuit Diagram and see Note B)

A. Connect the live wire (colored Brown, Red or Black) to the terminal block marked "L".

B. Connect the neutral wire (colored Black, Blue, White or Grey) or connect the second live wire (colored

Red or Orange) to the terminal block marked "N".

C. Connect the ground wire to the terminal block marked " " or to the green screw marked " ". Bare

grounding (earth) wires should be sleeved with green and yellow or green tubing.

Colors of live and neutral wires depend on voltage of supply service and requirements of Building and

Electrical Code having jurisdiction.

8. Reinstall hand drying chamber retained in step 2 into wall box housing using #2 PhilIips screw driver and

screws also retained in step 2 while being careful to not pinch cable arranged to route clear around hand

chamber in step 6.

9. Fasten the front panel onto the chassis box using the two (2) security screws retained in step 1 above

using the security wrench. Retain wrench for any possible service access during dryer lifetime. Turn ON

breaker at service panel (by others) and test dryer operation.

10. Record the unit S/N on the Registration Card and give this Owner’s Manual, the Installation Guide, Registration

Post Card and the security wrench to Owner or Facility Manager.

www.asijdmacdonald.com.au

www.asijdmacdonald.com.au

1800 023 441

ASI JD M a c D o n a l d Pty . L t d .

1. Make sure power supply breaker is switched off. Installation must be carried out in accordance with the

current edition of the local wiring regulations code having jurisdiction. Installation should be performed

only by a qualified electrician.

VAC

220

230

240

Vac

220

230

240

Inrush A(W)

2.86 (630)

2.99 (689)

3.13 (750)

Operating A(W)

1.91 (420)

2.00 (459)

2.08 (500)

1.91 (420)

2.00 (459)

2.08 (500)

Vac

220

230

240

Inrush A(W)

4.77 (1050)

4.99 (1148)

5.21 (1250)

Operating A(W)

3.82 (840)

3.99 (918)

4.17 (1000)

№

0135-2

0135-2

0135-2

Operating A(W)