the separate profiles of the b.1000 are made of aluminium. all the profiles are anodized after precision

cutting and accurate machining.

although anodized aluminium does not corrode under normal atmospheric conditions, regular care is

essential to maintain a good, decorative surface as well as to ensure its hygienic properties.

use a commercially available household cleaning agent for regular care and clean the surfaces with a

soft cloth. as a general rule, only wipe over with a damp cloth, do not wet-clean. it is imperative to avoid

harsh, abrasive cleaning agents and cleaning tools.

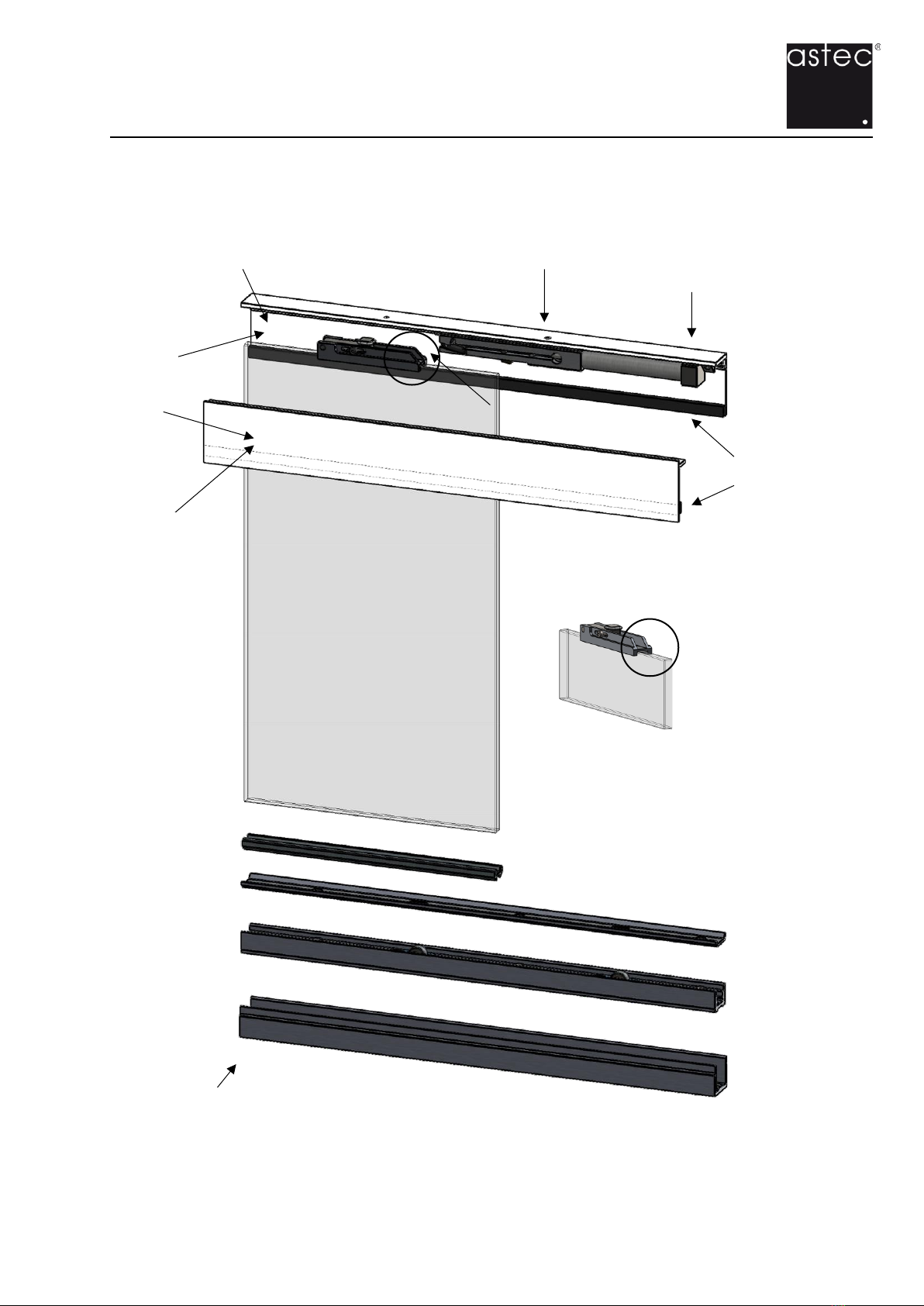

the bearings of the rollers are always sealed and lubricated for life. wipe the rollers with a damp cloth

at regular intervals. the collection of dust and other air contaminants can form a film. uneven running

and possible jamming of the rollers is the result. the floor track should be regularly cleaned with a

vacuum cleaner in order to remove coarse dirt in particular. the cover strips are in two sections and can

be removed with little effort if required. small stones and coarse dirt on the surface of the floor track

should be removed immediately as these can get stuck between the door guide profile and the cover

strip. this can lead to annoying scratching noises, surface damage and possible jamming of the doors.

please always use tools that are in good condition to avoid damage to the inner surfaces of the screws.

these are namely also a decorative element of the fitting.