5

4. INSTALLATION: _______________________________________________________________________________________________

4.1. Installation of the power supply

Always install the POWER SUPPLY of the EASY SALT system VERTICALLY on a solid and rigid surface (wall) as shown in the recommended

installation diagram (Figs. 1,2). In order to guarantee a good state of conservation, the POWER SUPPLY should be installed in a well-ventilated

dry place. Due to IP degree of the POWER SUPPLY the EASY SALT system should not be installed outdoors. The POWER SUPPLY should be

installed a bit distant from the electrolysis cell so that it cannot accidentally suffer water splashes.

Beware of corrosive atmosphere formation due to pH decreasing solutions (specially, those ones based on hydrochloric acid "HCl"). Do not

install the EASY SALT system near to any stores of these chemicals. We strongly recommend the use of chemicals based on sodium

bisulphate or diluted sulphuric acid. Power supply must be connected to the electrical control box of the pool, so that the pump and the EASY

SALT System are turned on (and off) simultaneously.

4.2. Installation of the electrolysis cell

The electrolysis cell is made of polypropylene in whose interior the electrodes are placed. The electrolysis cell must be always installed indoors

and after the pool filter, and after any other equipment that may be present (heat pumps, control systems, etc.).

The installation of the cell should allow easy access to the installed electrodes by the user. It is highly recommended to install the electrolysis

cell HORIZONTALLY in a place of the pipe that can be easily isolated from the rest of the installation by two valves, so that the tasks of

maintenance can be carried out with no need of partial or total draining of the swimming pool.

Where the cell is installed on a by-pass (recommended option), a valve to regulate the flow must be introduced. Prior to installation, please

consider the following commentaries might be considered:

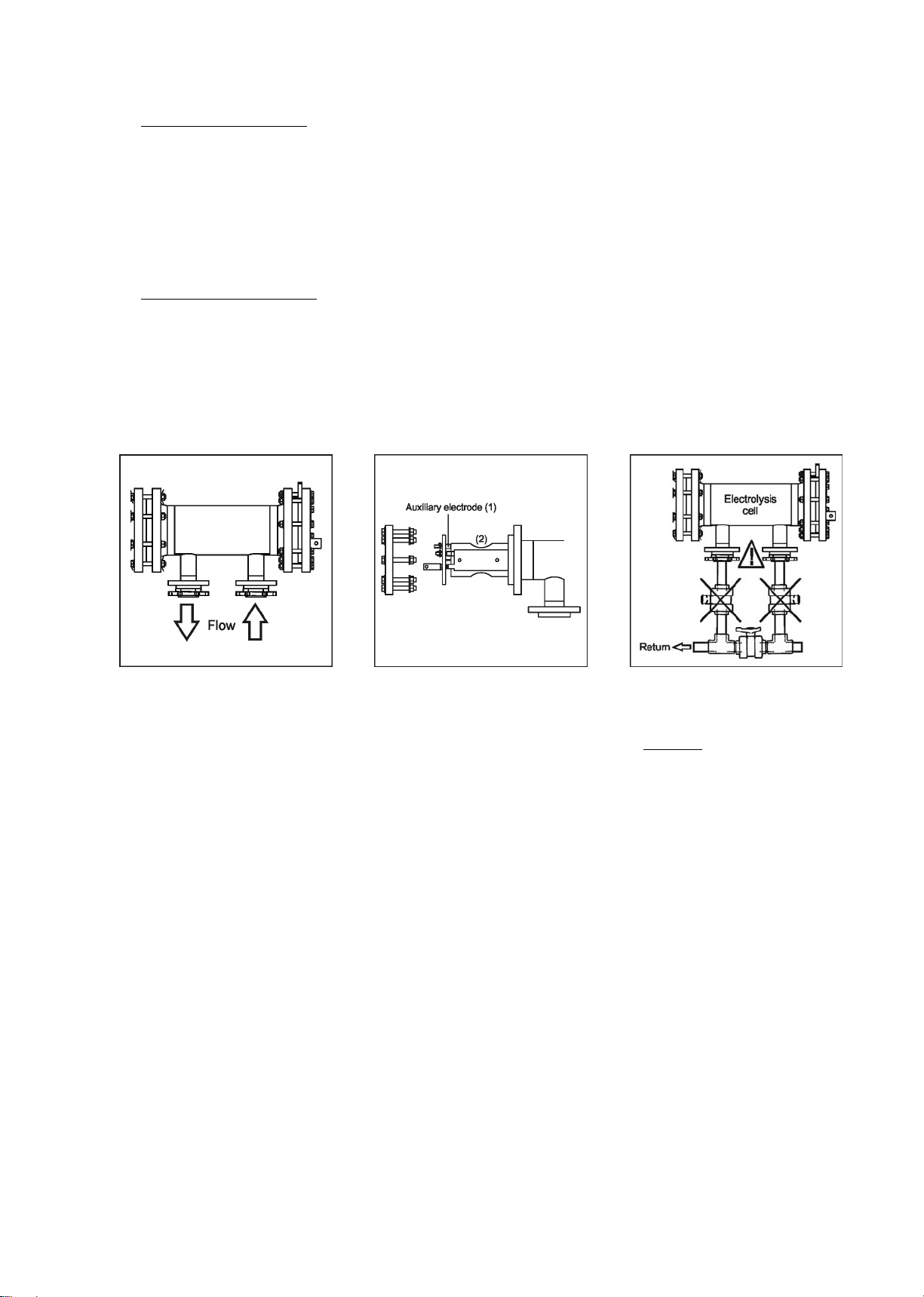

Fig. 3

Fig. 4

Fig. 5

1. Flow direction marked in the cell

must be respected. Recirculation

system must guarantee the minimum

flow stated in the Table of Technical

Specifications for each model (see

Section 9).

2. The system flow detector activates if

there is not recirculation (flow) of water

through the cell or if flow is very low. If

electrolysis gases are not properly

removed through the electrolysis cell,

the generated gas bubble electrically

isolates the auxiliary electrode

(electronic detection). Therefore, when

locating the electrodes in the cell, the

level sensor (auxiliary electrode) will

have to be located in the higher area of

the cell. The safest orientation is shown

in the recommended installation

diagram.

3. WARNING: if the in-out valves of the

electrolysis cell are closed

simultaneously, the flow detector (gas

detector) will not work correctly, with

the consequent risk of cell breakdown.

Although this situation is extremely

unusual, it can be easily avoided once

the equipment has been installed, by

locking at opened position the return

valve to the swimming pool, so it

cannot accidentally be manipulated.