OPERATION

1. Secure jackto suitable engine crane. Locate and

close release valve by turning lever clockwise firmly.

2. Operate by pumping handle until engine crane hook

reaches desired position.

3. Lower hook by gently turning the release valve lever

counterclockwise, never more than 1/2 turn. The

release valve system is metered, so please be care-

ful when lowering load.

BE SURE ALL TOOLS AND PERSONNEL ARE CLEAR

BEFORE LOWERING LOAD. DANGEROUS DYNAMIC

SHOCK LOADS ARE CREATED BY QUICKLY OPENING

AND CLOSING THE RELEASE VALVE AS THE LOAD IS

BEING LOWERED. THE RESULTING OVERLOAD MAY

CAUSE HYDRAULIC SYSTEM FAILURE WHICH COULD

CAUSE SEVERE PERSONAL INJURYAND/OR PROPERTY

DAMAGE.

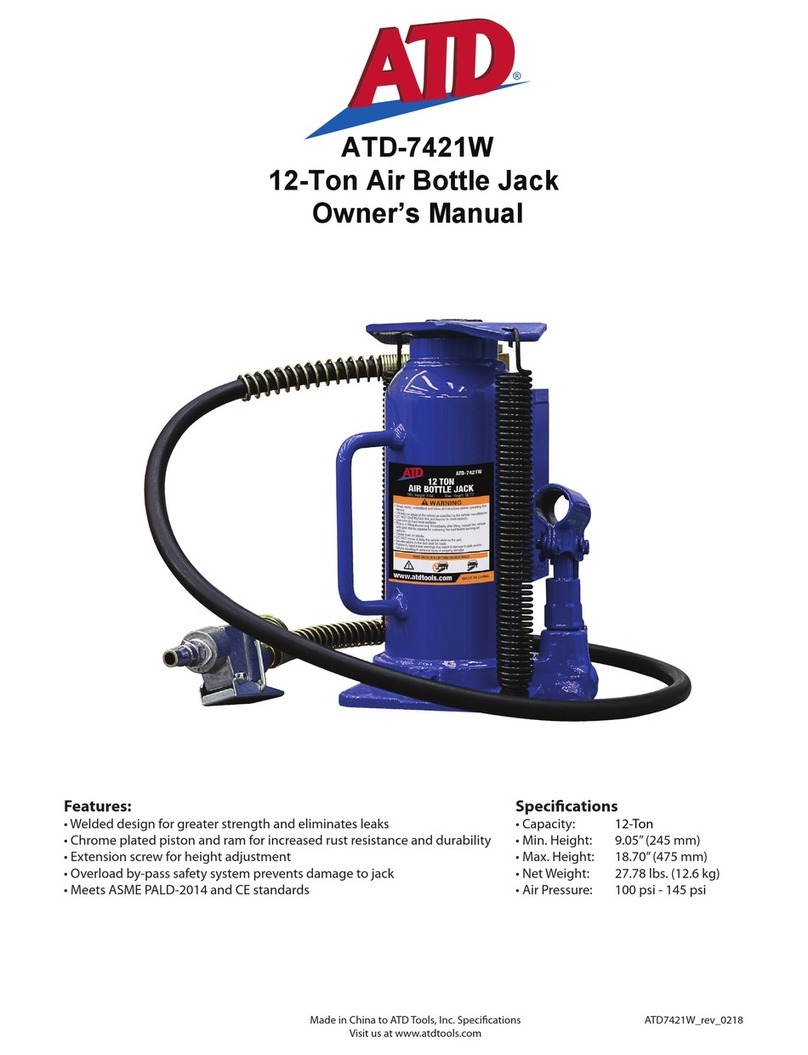

MAINTENANCE

Important: Use onlya good grade hydraulic jack oil.

Avoid mixing different types of fluid and NEVER use

brake fluid, turbine oil, transmission fluid, motor oil or

glycerin. Improper fluid can cause premature failure of

the jack and the potential for sudden and immediate

loss of load.

Adding Oil:

1. With ram fullylowered and pump piston fully de-

pressed, set jack in its upright, level position. Care-

fully remove from crane. Remove oil filler plug.

2. Fill until oil is level with the filler plug hole, re-install oil

filler plug.

Changing Oil:

For best performance and longest life, replace the com-

plete fluid supply at least once per year.

1. With ram fullylowered and pump piston fullyde-

pressed, remove the oil filler plug.

2. Lay the jack on its side and drain the fluid into a

suitable container.

Note: Dispose of hydraulic fluid in accordance

with local regulations.

3. Set jack in its level upright position.

4. Fill with good quality jack oil. We recommend Mobil

DTE 13 or equivalent. Reinstall oil filler plug.

Lubrication

1. A coating of light lubricating oil to pivot points, axles

and hinges will help to prevent rust and assure that

wheels, casters and pump assemblies move freely.

2. Periodically check the pump piston and ram for signs

of rust or corrosion. Clean as needed and wipe with

an oily cloth.

NEVER USE SANDPAPER ORABRASIVE MATERIAL

ON THESE SURFACES!

3. When not in use, store the jack with pump piston and

ram fully retracted.

3

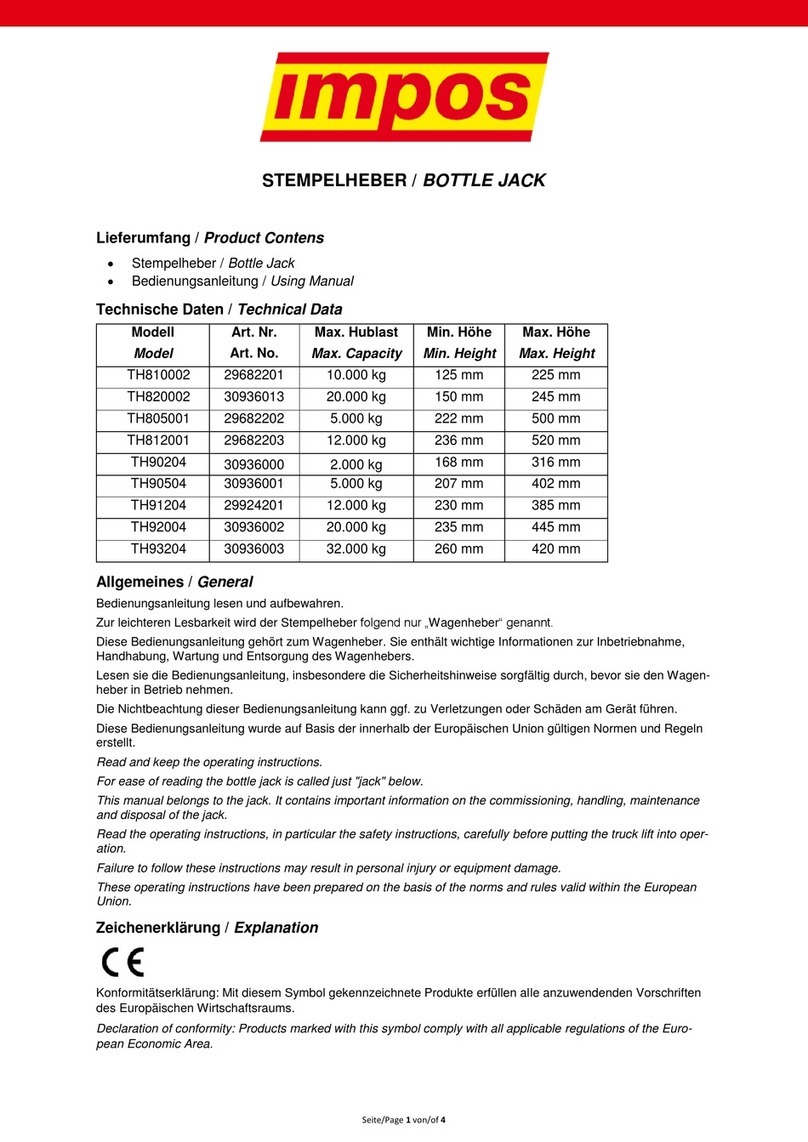

Possible Causes

Jack will not lift load

Jack bleeds off after lift

Will not lift to full extension

Release valve not tightly closed

Overload condition

Fluid level low

Fluid level low

Air trapped in system

Release valve not tightly closed

Overload condition

Hydraulic unit malfunction

Ensure release valve tightly closed

Remedy overload condition

Ensure release valve tightly closed

Remedy overload condition

Contact your supplier

Ensure proper fluid level

Ensure proper fluid level

With ram fully retracted, remove oil filler

plug to let pressurized air escape,

reinstall oil filler plug

TROUBLESHOOTING

Poor lift performance

Jack will not lower after unloadingReservoir overfilled

Linkages binding

Drain fluid to proper level

Clean and lubricate moving parts

noitcAevitcerroCmotpmyS