•Do not allow the hose to kink, twist, curl, crush, cut

or bend so tightly that the fluid flow within the hose is

blockedorreduced. Periodically inspect the hose for

wear, because any of these conditions can damage

the hose and possibly result in personal injury.

•Do not pull, position or move setup by the hose. Do-

ingsocan damage the hose and possibly cause per-

sonal injury.

•Hose material and coupler seals must be compatible

with hydraulic fluid used. Hoses also must not come

in contact with corrosive materials such as battery

acid, creosote-impregnated objects and wet paint.

Hose deterioration due to corrosive material can re-

sultin personal injury. Never paint acoupler or hose.

•Theusermust be a qualified operator familiar with the

correctoperation, maintenance,anduseof cylinders.

Lack of knowledge in any of these areas can lead to

personalinjury.

•Read and understand all safety and warning decals

and instructions.

•Useonly approvedaccessoriesandapproved hydrau-

lic fluid. Hoses, seals and all components used in a

system must be compatible with the hydraulic fluid

used.

•Do not exceed the rated capacity of the cylinder. Ex-

cess pressure can result in personal injury.

•Inspecteachcylinderandcouplerbeforeeachuseto

preventunsafe conditionsfromdeveloping.

•Do not use cylinders if they are damaged, altered or

in poor condition.

•Donotusecylinderswith bent or damaged coupler or

damaged threads.

•Undercertainconditions,theuseofanextensionwith

a hydraulic cylinder may not be advisable and could

present a dangerous condition.

•Avoid pinch points or crush points that can be cre-

ated by the load or parts of cylinder.

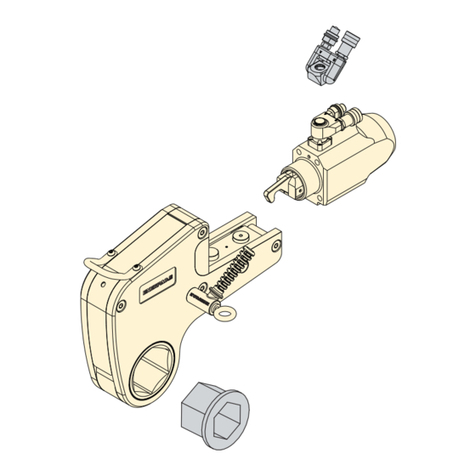

•Tohelpprevent material

fatigue if the cylinder is to

be used in a continuous

application, the load

should not exceed 85% of

the rated capacity.

•Cylinder must be on a

stable base which is able

to support the load while

pushing or lifting.

•Ensure cylinder is fully

engagedinto/ontoadapt-

ers, extension accessories.

4

•Tohelpprevent personalinjury,useshims,frictionma-

terialor constraintstopreventslippage of thebaseor

load.

•Donotoff-centerloadsonacylinder.Theloadcantip

or the cylinder can "kick out" and cause personal in-

jury.

•Do not use the locking collar on threaded piston as a

stop. The threads may shear resulting in loss of the

load.

•Do not create an overload condition where force ex-

ertedby one cylinder will intensify downward forceon

another cylinder.

•If this component is used to lift or lower loads, be

certain that the load is under operator control at all

times and that others are clear of the load. Do not

drop the load.

•Asthe load islifted,useblocking and cribbing toguard

againstafallingload.

•Neverallow personnel to work on, under or around a

loadbeforeitisproperlysupported byappropriateme-

chanicalmeans.Neverrelyonhydraulicpressurealone

to support load.

•Allpersonnel must be clear beforelowering.

•Never try to disassemble a hydraulic cylinder, Refer

repairstoqualified, authorized personnel.

IMPORTANT

•Keep cylinder clean at all times.

•Whenthe cylinder is not is use, keep the ram(s) fully

retracted.

•Use an approved, high-grade pipe thread sealant to

sealallhydraulicconnections.Teflon tape can be used

ifonlyonelayerof tape is used and it is applied care-

fully(two threadsback)toprevent the tapefrombeing

introducedintohydraulicsystem.Apieceoftapecould

travelthrough thesystemandobstructthe flowoffluid

andadversely affectfunction.

•NeverattachANYcomponentnotauthorizedbymanu-

facturer.

•Neveruse other than factory provided and/or author-

ized fasteners.

KNOWYOUR SYSTEM

Your cylinder, hose(s), couplings and pump all must be

rated for the same maximum operating pressure, cor-

rectlyconnectedand compatible with the hydraulic fluid

used.Animproperlymatchedsystemcan causethesys-

temto fail and possibly causeseriousinjury.If you are in

doubt,consult your nearest ATD Hydraulics Dealer.

Center loads on cylinder

!

!