WARNING

THIS MANUAL HAS BEEN PREPARED FOR WORKSHOP PERSONNEL EXPERT IN THE USE OF THE MACHINE

(OPERATOR) AND TECHNICIANS RESPONSIBLE FOR ROUTINE MAINTENANCE (MAINTENANCE FITTER);

READ THE MANUAL BEFORE CARRYING OUT ANY OPERATION WITH THE RIM REPAIR AND/OR PACKING . THIS

MANUAL CONTAINS IMPORTANT INFORMATION REGARDING :

-RIM REPAIR MACHINES SAFETY

-THE PERSONNEL SAFETY OF OPERATORS AND MAINTENANCE WORKERS

THE MANUAL IS AN INTEGRAL PART OF THE RIM REPAIR, WHICH IT SHOULD ALWAYS ACCOMPANY EVEN IF THE UNIT

IS SOLD.

THE MANUAL MUST BE KEPT IN PROXIMITY OF THE RIM REPAIR, IN AN EASILY ACCESSIBLE PLACE.

THE OPERATOR AND MAINTENANCE STAFF MUST BE ABLE TO LOCATE AND CONSULT THE MANUAL QUICKLY

AND AT ANY TIME.

LIFTING, TRANSPORT , UNPACKING , ASSEMBLY , STARTING UP , INITIAL ADJUSTMENT AND TESTING ,

EXTRAORDINARY MAINTENANCE , REPAIR , OVERHAULS, TRANSPORT AND DISMANTLING OF THE RIM REPAIR

MACHINE MUST BE PERFORMED BY SPECIALISED PERSONNEL FROM THE LICENSED DEALER OR A SERVICE

CENTRE AUTHORISED BY THE MANUFACTURER .

THE MANUFACTURER DECLINES ALL RESPONSIBILITY FOR INJURY TO PERSONS OR DAMAGE TO VEHICLES OR

OBJECTS WHEN ANY OF THE ABOVE MENTIONED OPERATIONS HAS BEEN PERFORMED BY UNAUTHORISED

PERSONNEL OR WHEN THE RIM REPAIR HAS BEEN SUBJECT TO IMPROPER USE.

THIS MANUAL INDICATES ONLY THE OPERATIVE AND SAFETY ASPECTS THAT MAY PROVE USEFUL TO THE

OPERATOR AND MAINTENANCE WORKER, IN BETTER UNDERSTANDING THE STRUCTURE AND OPERATION OF THE

RIM REPAIR AND FOR BEST USE OF THE SAME.

IN ORDER TO UNDERSTAND THE TERMINOLOGY USED IN THIS MANUAL, THE OPERATOR MUST HAVE SPECIFIC

EXPERIENCE IN WORKSHOP, SERVICE, MAINTENANCE AND REPAIR ACTIVITIES.

ALL PACKING,LIFTING , HANDLING , TRANSPORT AND UNPACKING OPERATIONS ARE TO BE PERFORMED

EXCLUSIVELY BY EXPERT PERSONNEL WITH KNOWLEDGE OF THE RIM PRES AND THE CONTENTS OF THIS MANUAL.

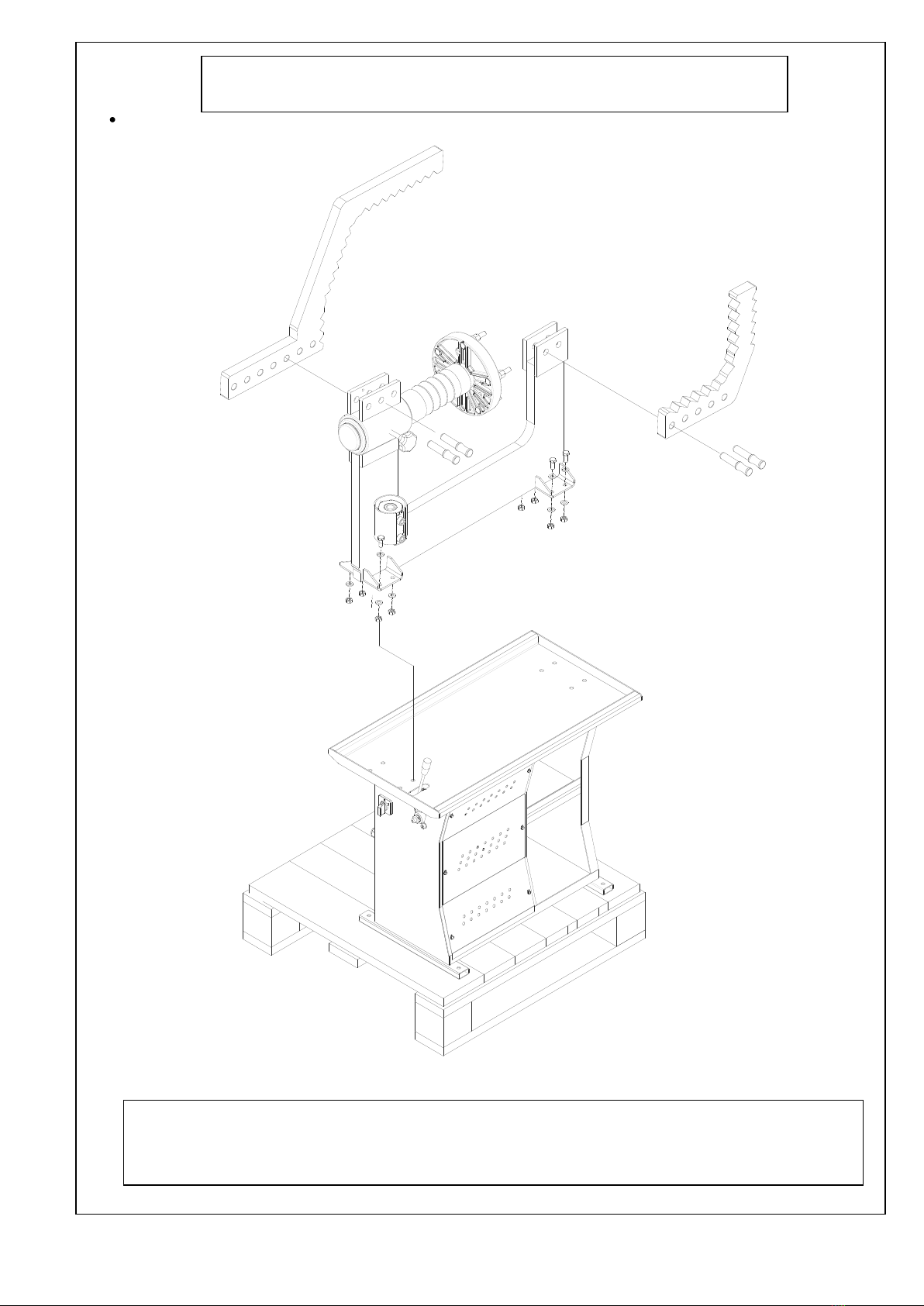

PACKING

LIFTING AND HANDLING

THE PALLETS MUST BE MOVED WITH A LIFT TRUCK.THE EQUIPMENT CHOSEN MUST BE SUITABLE FOR SAFE LIFTING

AND MOVING, BEARING IN MIND THE DIMENSIONS , WEIGHT , BARYCENTRE , JUSTS AND FRAGILE PARTS NOT TO BE

DAMAGED.

STORAGE

PACKED MACHINERY MUST ALWAYS BE KEPT IN A COVERED , PROTECTED PLACE AT A TEMPERATURE BETWEEN –10

C TO +40 C AND MUST NOT BE EXPOSED TO DIRECT SUNLIGHT.

PACKAGES STACKING

THE TYPE OF PACKING ALLOWS THE POSSIBILITY OF STACKING UP TO 2 PACKAGES, PROVIDED THEY ARE

RESTRAINED TO PREVENT FALLING.

UP TO 2 PALLETS MAY BE STACKED ONE UPON THE OTHER ON LORRIES OR IN CONTAINERS IF PROPERLY

POSITIONED AND PROVIDED THEY ARE RESTRAINED TO PREVENT FALLING.

OPENING CRATES

WHEN THE CRATES ARRIVE, CHECK THAT THE MACHINE HAS NOT BEEN DAMAGED DURING TRANSPORT AND THAT

ALL THE LISTED PARTS ARE PRESENT. THE CRATES MUST BE OPENED USING ALL POSSIBLE PRECAUTIONARY

MEASURES TO AVOID DAMAGING THE MACHINE OR ITS PARTS. MAKE SURE THAT PARTS DO NOT FALL FROM THE

CRATE DURING OPENING.

DISPOSAL OF CRATES

THE WOOD OF THE PALLETS AND THE STRECH FILM MAY BE RE-USED.

PACKING , TRANSPORT , STORAGE

THE RIM REPAIR MACHINE IS SENT ON PALLETS, COVERED WITH STRECH FILM

WEIGHING APPROXIMATELY 190 KG