3.1.1 Connect the charging gun to the charging device. If gun A is used, click A on the standby

interface, If gun B is used, click B on the standby interface.

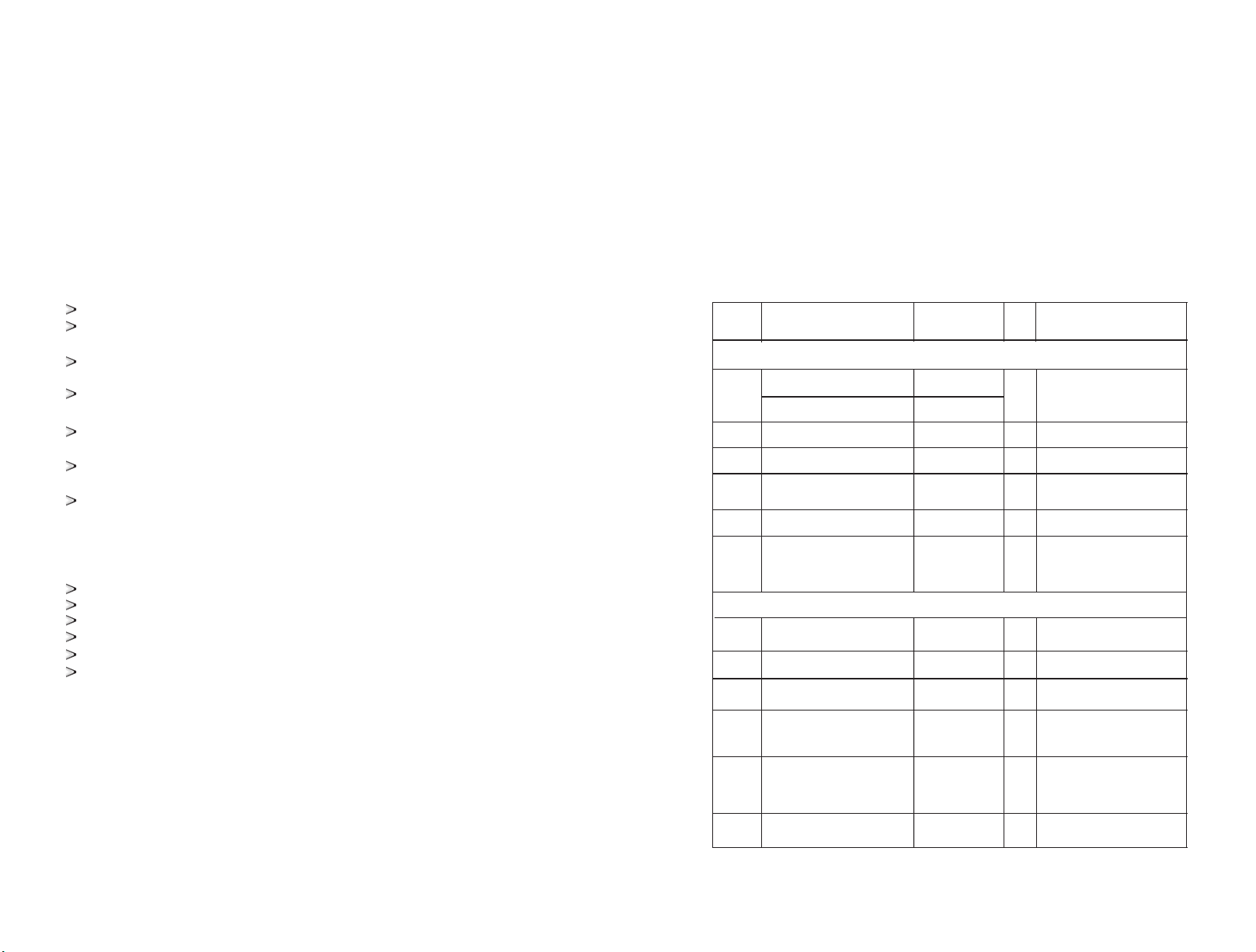

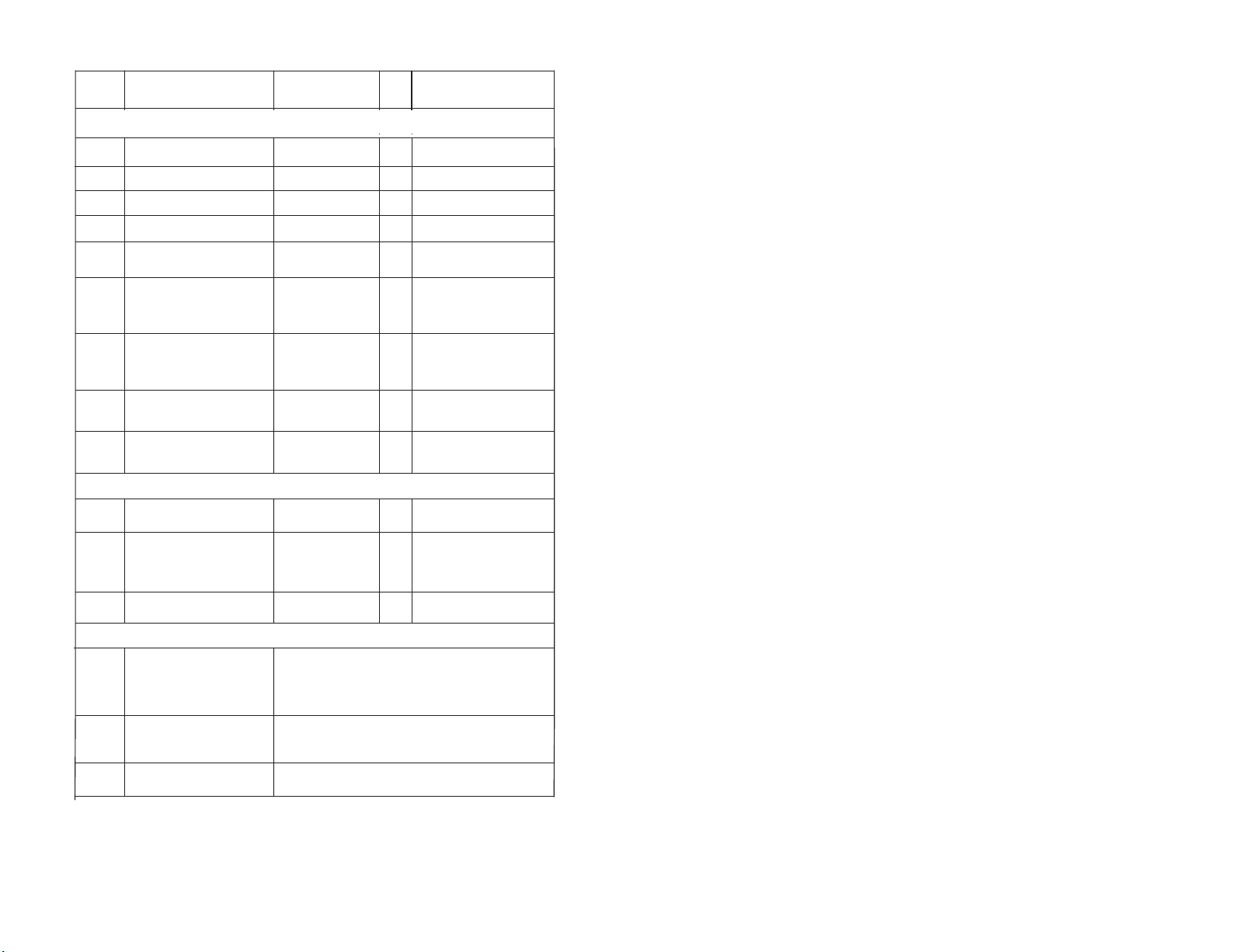

b) Storage

① Transaction data is stored in non-volatile memory as records.

②Ensure that the data stored correctly, continuously, completely and effectively.

③ Keep not less than 10,000 records of space, the transaction records will be stored, the charger

can promptly prompt for data acquisition.

2.2.6 Billing function

Support APP payment.

2.2.7 Control function

Charge monitoring unit can adapt to a variety of charger operation, to achieve constant current

limit voltage charging → constant voltage limit current charging → stop charging, the correct

charging process.

2.2.8 Alarm function

Charger DC output anomalies, rectifier unit alarm / fault, DC output over / under voltage, DC

output overcurrent, charger input switch trip / fuse blown, charging monitoring unit

communication interruption, monitoring unit fault, etc, the monitoring unit can sound and light

alarm, and display fault information on HMI.

2.2.9 Event recording function

Charger fault, charging start / end time, etc. all have event records, which is stored in non-volatile

memory.

2.2.10 Operation authority function

The DC charger has operation authority password management function. The administrator can

set parameters and check the charging data with the password.

2.2.11 Time-correction function

The charger can receive the right time command of the zone monitoring terminal to meet the

requirements of PPS (second pulse) and PPM (minute pulse).

2.2.12 Protection function test

a) Output over-voltage protection

Turn off the output when the output voltage is greater than or equal to the set voltage value.

b) Overcurrent protection

Turn off the output when the output current is greater than the set current value.

c) Open circuit protection

Charger will shut down automatically in case of short-circuit fault; It can automatically resume

work after troubleshooting.

d) Plug out under load protection

Unplug the plug in the charging state, the corresponding contactor protection circuit

immediately disconnected, at the same time the charger cut off the power supply to the socket to

achieve plug removal double protection.

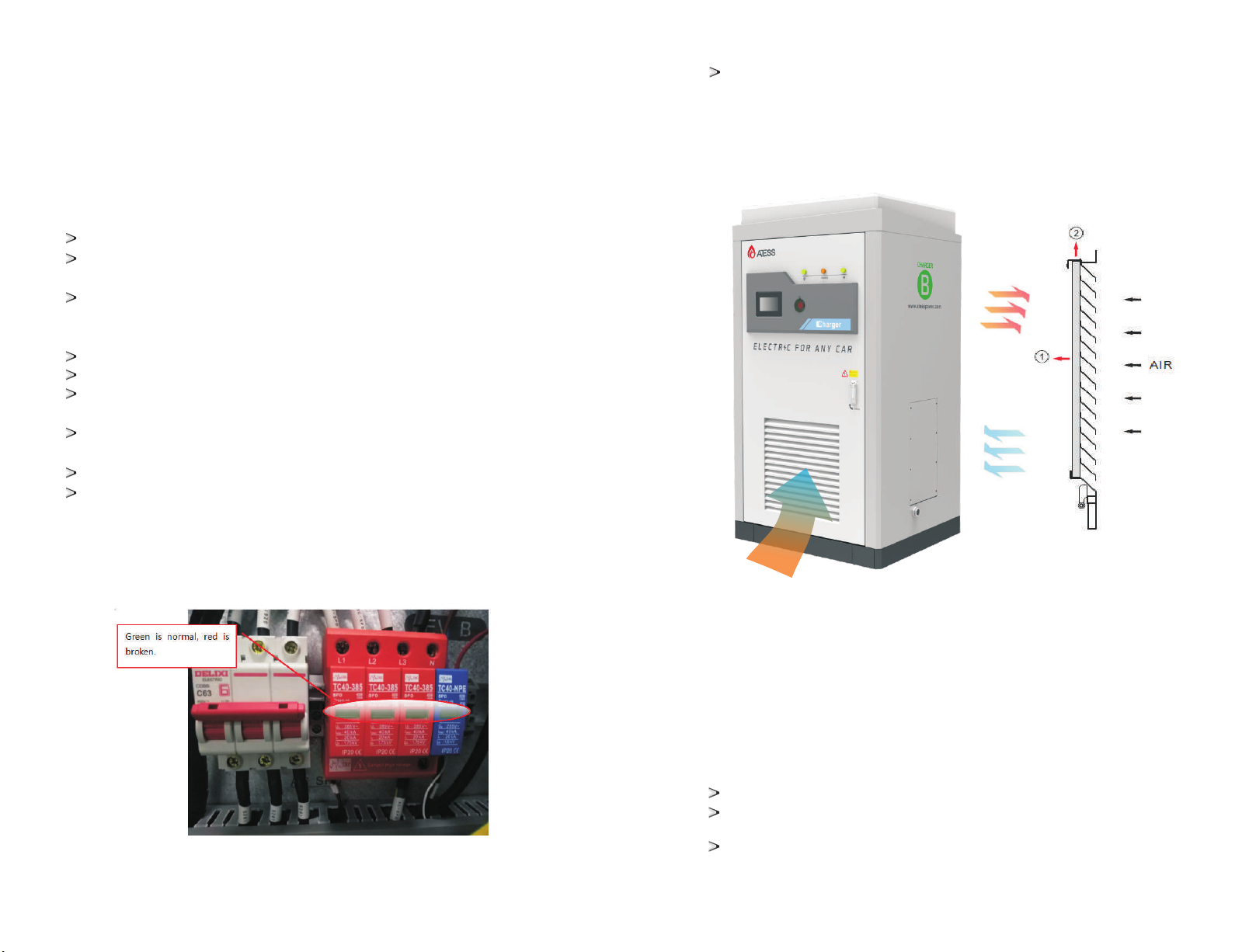

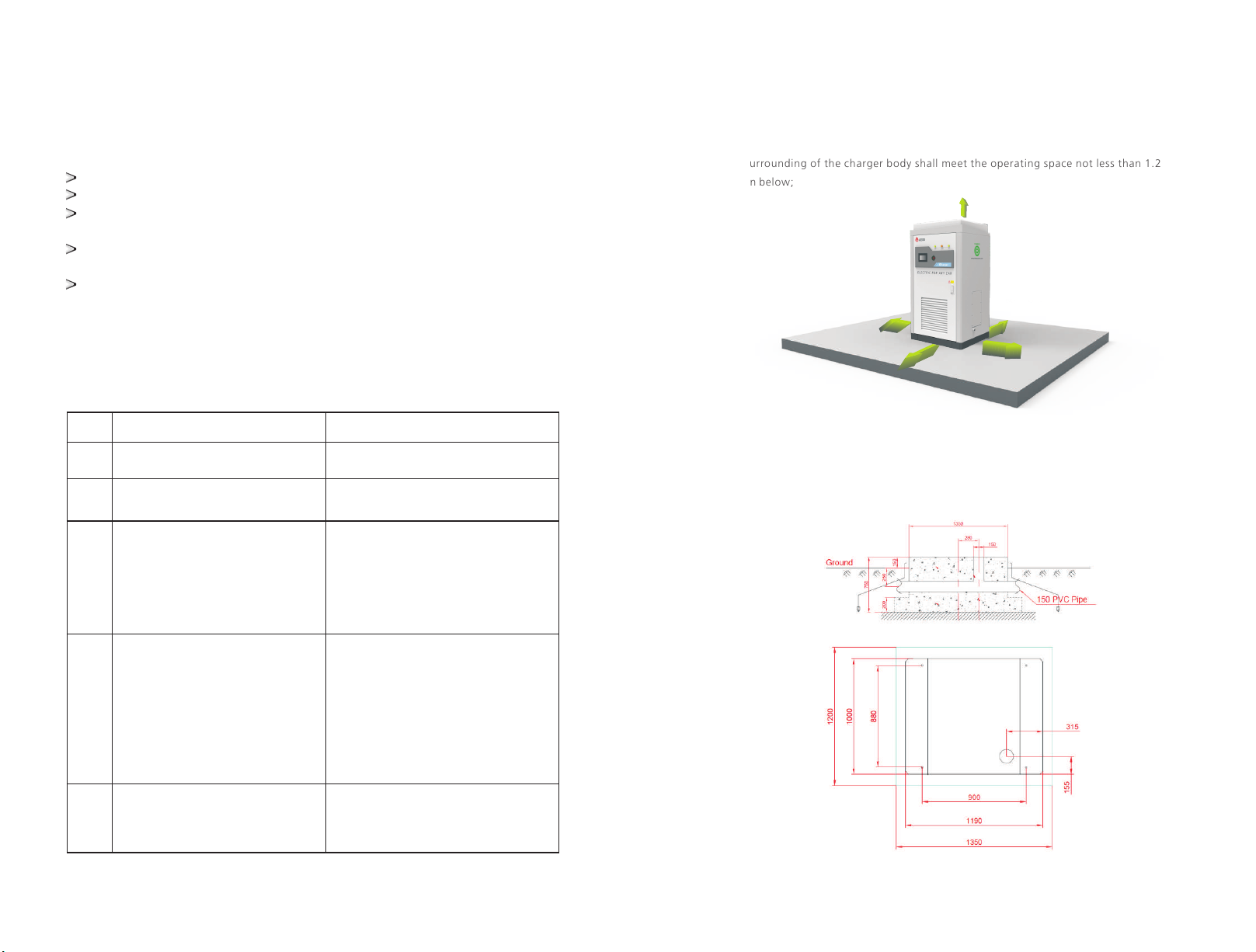

3Operation Instructions

3.1 Operation process

3.1.2 If the charging mode is the Plug&Charge mode, the charger will directly enter the

charging process and start charging. If the charging mode is the APP/RFID mode,You need to

swipe the card to charge or open the mobile app, Scan the QR code on the left side of the screen,

Enter the charging process according to the app operation instructions and start charging.

During charging, the interface of charger will display current SOC of battery, voltage, current,

electric quantity, charging time and remaining charging time.

Fig3.1.1 Home Screen

Fig3.1.2 Swipe the QR Code

3.1.3 Click the menu button in the lower left corner to enter the pile setting interface.

10

9