10

9

No. Parameters Function description

1

2

3Charger IP

Server URL2

Server URL1 Server address setting, used to set domain or IP

address of back-office server.

IP setting of the charging equipment

Address of backup server. This parameter is not

available now, reserved for future use.

4Subnet mask Subnet mask setting

5Gateway Gateway setting

6DNS DNS server address

7MAC Addr MAC address

8Server IP Server IP address

9Server port Server port number

10 WIFI SSID

WIFI SSID setting, to set the name of the wireless

network to which the charging equipment is to

be connected. A reserved function for future use

11 WIFI Key WiFi password setting. A reserved function for

future use

12 Authentication Key OCPP login authentication setting

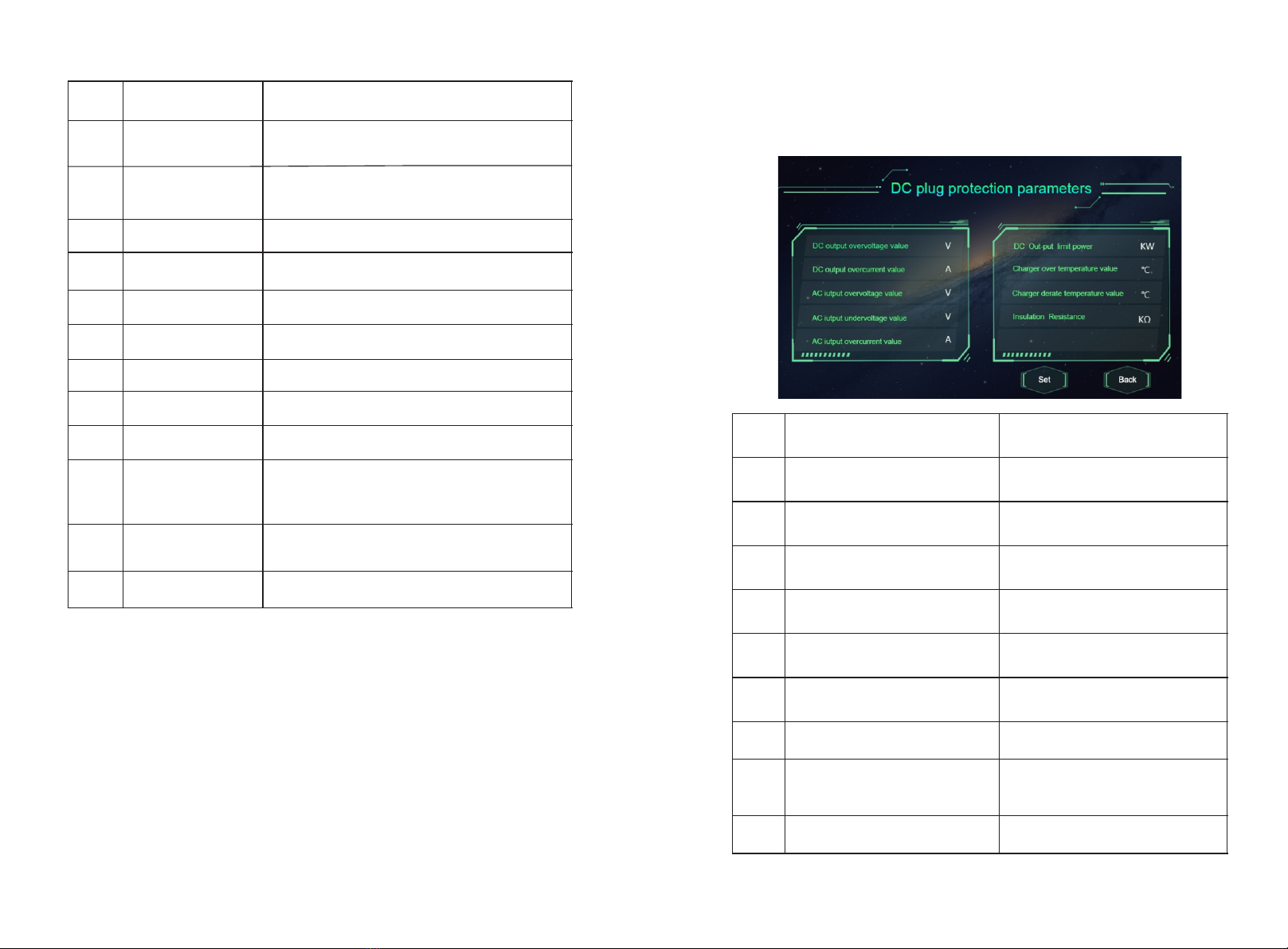

No. Parameters Function description

1

2

3

4

5

6

7

8

9

DC output overvoltage value

DC output overcurrent value

AC input overvoltage value

AC input undervoltage value

AC input overcurrent value

DC output limit power

Charger over temperature value

Charger derate temperature value

Insulation Resistance

Over voltage limit setting of DC

output

Over current limit setting of DC

output

Over voltage limit setting of AC

input

Under voltage limit setting of AC

input

Over current limit setting of AC

input

Power limitation setting of DC

output

Over temperature limit setting of

charging connector

Charging connector’s temperature

at which the charging equipment

starts decreasing output power

The min value of insulation

resistance

If the charger is connected to the server through the network cable, the Charger

IP, Subnet mask and Gateway need to be set. Through WiFi, you need to set WiFi

SSID and WiFi Key. With 4G, you can connect to the server by installing a SIM

card.

4.3 Protection parameters

The protection-related parameters, such as voltage, current, temperature, power,

etc.