11 12

(1) When PV power is higher than load power, PV supply priority to load power,

then to the battery charge.

(2) Battery discharge automatically when PV power is lower than load power.

CAUTION

When the ambient temperature is too high, it is normal the

inverter reduces the output power. However, if this frequently

happens, check the cooling surface of the inverter or place the

inverter in better ventilation conditions place. If the inverter fan is

dirty, please clean the fan, if there is problem with the inverter

internal electrical, please seek help from professional services.

3.4.7 Fault mode

When the DC power system fails, the inverter will immediately disconnect the AC

contactor and enters into the fault mode, so as to ensure the safety of the system.

Inverter continuously monitors fault status and will not enter charge and discharge

mode until the fault is eliminated.

3.4.8 Permanent fault mode

When the DC power system is in serious failure, the inverter will immediately

disconnect the AC contactor and enters into the Permanent fault mode, so as to

ensure the safety of the system. For example: inverter module failure etc. please

contact your local dealer or ATESS directly when inverter enters permanent fault

mode, repairmen on site is not allowed without authorization of ATESS.

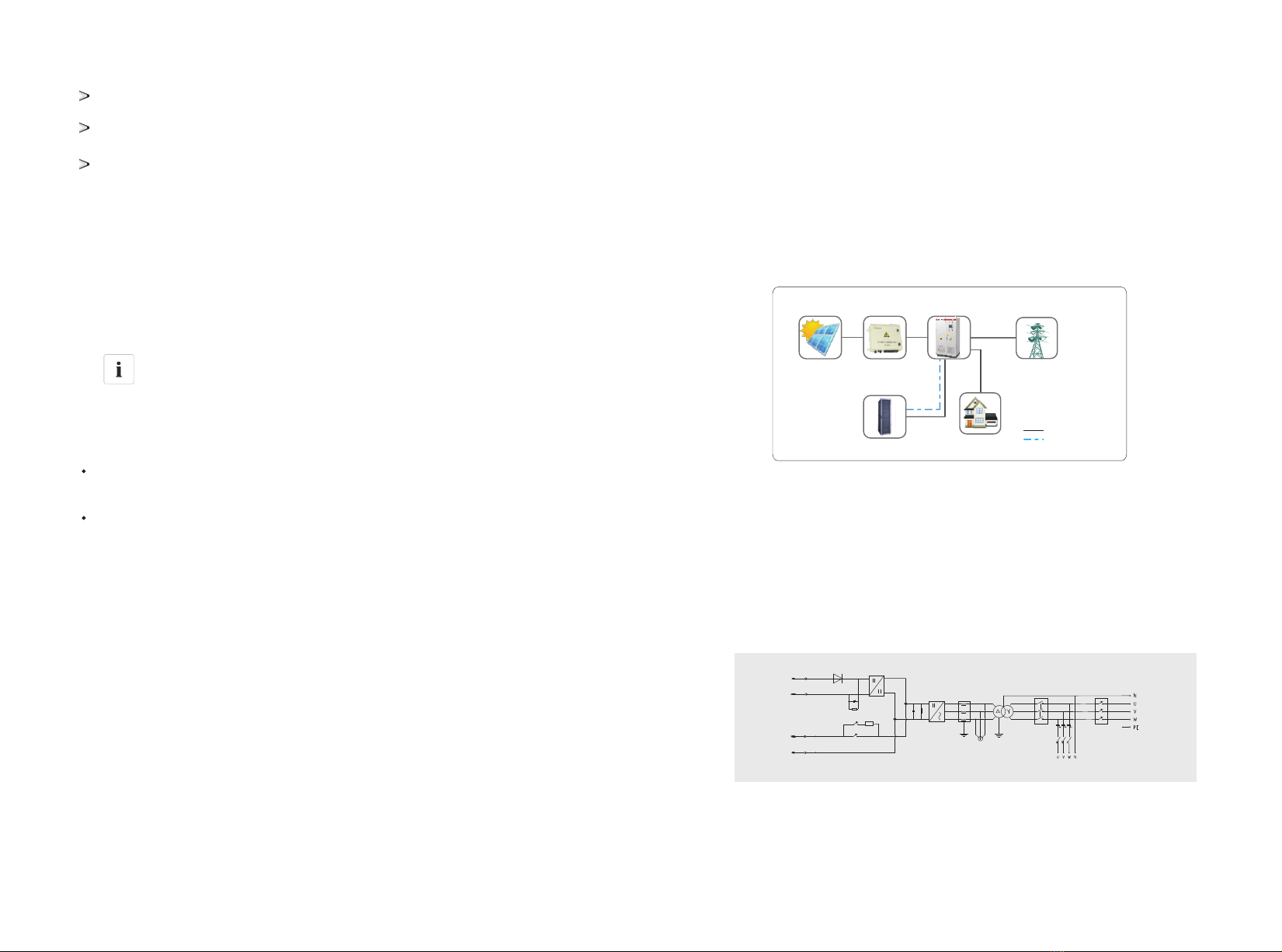

.Operation logic:

When grid power on, HPS can switch into on-grid mode automatically; when grid

power off, HPS can switch into off-grid mode automatically.

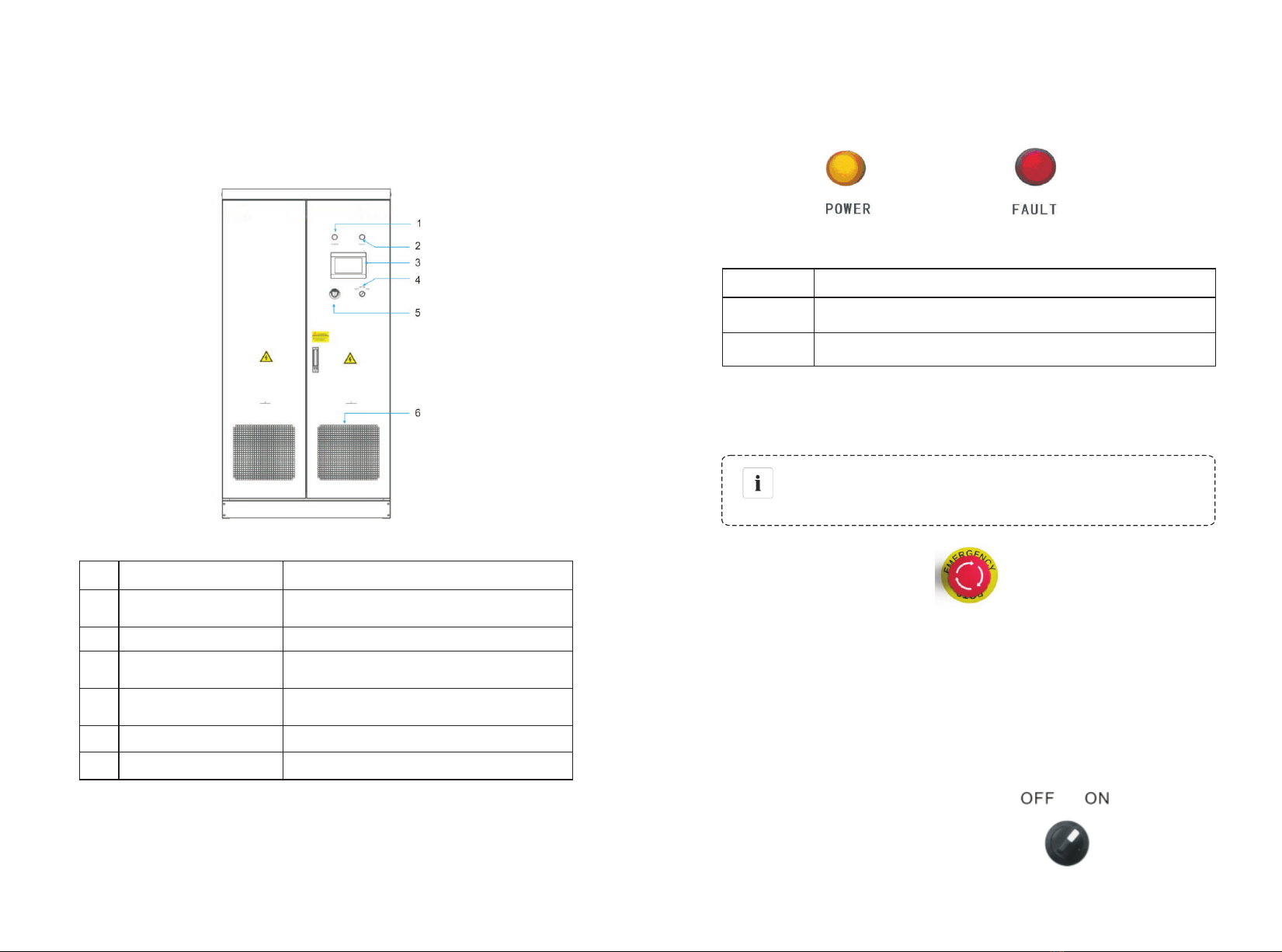

It displays the inverter’s operating parameters, power generation, and faulty

information record. Please refer to Section 6, for details.

Touch screen

3.4.5 PV charger mode

operation logic:

1) PV charges battery individually, does not affect bypass automatic switch

function.

2) After boot, HPS can switch into PV Charger mode automatically if any

anomalies detected.

3) At PV Charger mode, HPS will switch into on-grid mode when grid detected back

to be normal.

4) At PV Charger mode, when grid normal, start the inverter via the LCD, then HPS

run in off-grid mode.

5) At off-grid mode, HPS can stop the inverter and switch into PV Charger mode

3.4.6 On/Off-gird switch

HPS50 connected to battery ,PV on the DC side, and grid,load on the AC side;

Close the ac/dc circuit breaker and start-stop knob, HPS30 enter waiting status;

operation logic:

1) Battery will not discharge when PV power is insufficient, micro-grid will supply

to load and battery

2) operation state

a. When PV power is higher than charging power; PV will supply priority to battery

and the remaining to load. Output power is limited under 50% of load power.

b. When PV power is supply priority to battery, micro-grid charge battery.

3.4.4 Micro-grid backup priority mode (generator mode)

3.4 Operation mode define

3.4.1. Off-grid mode

((1) Grid supplies power to load and charges battery when PV power insufficient.

(2)When the back-flow-prevention works, PV power can meet battery charge and

load power.

(3) operation state

A.PV supply priority to the load, the remaining to load and grid when PV power is

higher than load power

B. When PV power is lower than the charging power, PV supply priority to battery,

the grid supplies to load and battery.

3.4.2On-grid backup priority mode

(1)At this mode, the inverter can prevent the current from flowing back by default,

PV will only need to meet battery charge and load power.

(2)Valley price: working logic is the same to the backup priority mode’s. PV and

grid supply priority to battery, the remaining to load.

(3)Fair price:

A. Battery can neither discharge nor be charged by grid.

B.PV power supply priority to load, the remaining to battery when PV power is

higher than load power.

C. When PV power is lower than load power, PV and grid supply to load.

(4)Peak price:

A. Grid will not charge battery.

B. When PV power is higher than load power, PV supply to load , the remaining to

battery.

C. When PV power is lower than load power, there are two conditions:

a. When battery voltage is normal, PV and battery supply to load.

b. When the battery is under voltage, battery will not discharge, PV and grid supply

to load only, not to battery.

3.4.3On-grid economic priority mode