ATH 7226 User manual

OPERATING INSTRUCTIONS

ATH 7226

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-01

Manufacturer ATH-Heinl GmbH & CO.KG

- 2 -

Contents

1.0 INTRODUCTION ................................................................................................................... - 3 -

1.1 General Information ........................................................................................................... - 3 -

1.2 Description ........................................................................................................................ - 4 -

1.3 Operation.......................................................................................................................... - 6 -

1.4 Technical Data ................................................................................................................ - 12 -

1.5 Scale Drawing ................................................................................................................. - 13 -

2.0 INSTALLATION ................................................................................................................... - 14 -

2.1 Transport & Storage Conditions ........................................................................................ - 14 -

2.2 Unpacking the machine .................................................................................................... - 15 -

2.3 Delivery Contents ............................................................................................................ - 15 -

2.4 Location .......................................................................................................................... - 16 -

2.5 Fixing ............................................................................................................................. - 17 -

2.6 Electrical Connection ........................................................................................................ - 18 -

2.7 Pneumatic Connection ...................................................................................................... - 18 -

2.8 Hydraulic Connection ....................................................................................................... - 18 -

2.9 Assembly ........................................................................................................................ - 19 -

2.10 Completion of Work ...................................................................................................... - 20 -

3.0 OPERATION ....................................................................................................................... - 21 -

3.1 Operating Instructions ..................................................................................................... - 21 -

3.2 Basic Information ............................................................................................................ - 22 -

4.0 MAINTENANCE ................................................................................................................... - 23 -

4.1 Consumables for installation, maintenance and servicing..................................................... - 23 -

4.2 Safety Regulations for Oil ................................................................................................. - 24 -

4.3 Notes ............................................................................................................................. - 24 -

4.4 Maintenance or Service Plan ............................................................................................. - 25 -

4.5 Troubleshooting / Error Display and Solutions .................................................................... - 26 -

4.6 Maintenance and Service Instructions ................................................................................ - 27 -

4.7 Disposal .......................................................................................................................... - 28 -

5.0 EG-/EU-KONFORMITÄTSERKLÄRUNG / EC-/EU-DECLARATION OF CONFORMITY...................... - 29 -

6.0 APPENDIX .......................................................................................................................... - 30 -

6.1 Pneumatic circuit diagram ................................................................................................ - 30 -

6.2 Electric circuit diagram ..................................................................................................... - 31 -

6.3 Hydraulic circuit diagram .................................................................................................. - 32 -

7.0 WARRANTY CARD ............................................................................................................... - 33 -

7.1 Scope of the Product Warranty ......................................................................................... - 34 -

8.0 INSPECTION LOG ............................................................................................................... - 35 -

8.1 Installation and Handover Log .......................................................................................... - 36 -

8.2 Inspection Plan ................................................................................................................ - 37 -

8.3 Visual inspection (authorised expert) ................................................................................. - 38 -

9.0 SPARE PART BOOK ............................................................................................................. - 42 -

10.0 NOTES ............................................................................................................................... - 68 -

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-01

Manufacturer ATH-Heinl GmbH & CO.KG

- 3 -

1.0 INTRODUCTION

1.1 General Information

THESE INSTRUCTIONS ARE AN INTEGRAL PART OF THE MACHINE.

THEY MUST BE READ AND UNDERSTOOD BY THE USER.

NO LIABILITY IS ASSUMED FOR ANY DAMAGES CAUSED BY FAILURE TO

FOLLOW THESE INSTRUCTIONS OR THE VALID SECURITY PROVISIONS.

WARNING: Follow the instructions to prevent injury or damage.

TIP: Provides more information on functionality and tips for using the device efficiently.

Appropriate protective clothing must be worn for all work on the described system.

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-01

Manufacturer ATH-Heinl GmbH & CO.KG

- 4 -

1.2 Description

1.2.1 Machine description

1. Operating unit 2. Switch for mounting head & carriage

3. Switch to open/close clamping jaws

4.

Pedal turner left

-

right clamping head

5. Mounting lever bracket 6. Electrical control box

7. Electrical motor

8. Oil tank

9. Hydraulic valve 10. Valve clamping cylinder

11. Pressure manometer 12. Gearbox

13. Gearbox motor

14. Clamping head

15. Clamping jaws 16. Clamping jaws

17. Mounting lever and disc 18. Pressure limiting valve

19. Mounting arm twist lock

20. Mounting arm

21. Sliding plate for wheel mounting 22. Retaining plate for mounting head

23. Lateral lock for mounting head 24. Manual lateral shift

25. Cylinder for hydraulic lateral shift

6

4

3

2

5

1

7

8

9

10

11 12 13 14 15

16

17

18

19

20

21

22

23

24

25

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-01

Manufacturer ATH-Heinl GmbH & CO.KG

- 5 -

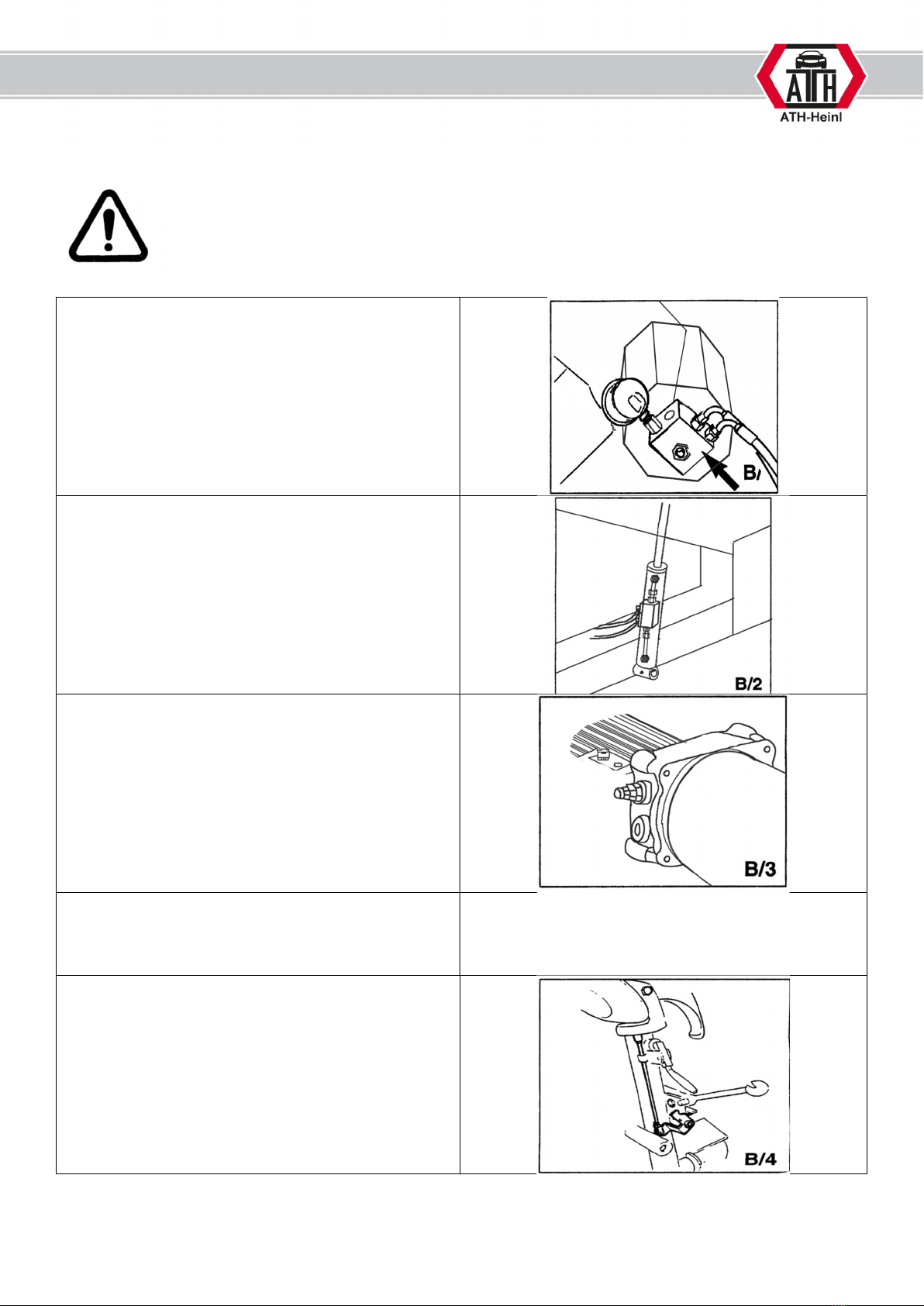

1.2.2. Safety Equipment Description

The tyre changer has the following safety features

WARNING!!

Removal and manipulation of the machine's safety equipment

violates European safety regulations and absolves the manufacturer of any

liability.

Check valve for the clamping cylinder of the 4-jaw

clamping unit (swivel connection)

Double seal check valve on the lift cylinder of the

boom.

Pressure relief valve with factory setting of 160 bar

± 5%

This limits the hydraulic pressure and is adjustable.

Overload protection for hydraulic motor (in the

electrical control box).

This cuts off the power supply when the engine

overheats

Mechanical locking of the tool arm

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-01

Manufacturer ATH-Heinl GmbH & CO.KG

- 6 -

1.3 Operation

1.3.1 Review of the different functions

Before using the tyre changer, check all functions with the operating part to ensure the machine is working

properly. This should be done before mounting.

WARNING!!

When operating the mounting machine, pay attention to all moving parts.

Make sure there is enough safety clearance. Make sure there are no other

people in the work area.

WARNING!!

Always keep enough safety clearance when loosening the mounting arm so

that it does not tilt outwards under tension.

WARNING!!

Ensure that there are no persons or objects in the working area of the

machine.

WARNING!!

When closing the jaw chuck, the process must be stopped immediately when

the minimum position is reached.

When tightening the rim, stop immediately when the maximum pressure is

reached. For aluminium rims, check the clamping pressure and set it lower if

required.

Failure to comply with this instruction may result in serious damage to the

mounting machine.

1.3.2 Precautions during tyre assembly

Before mounting the tyre, the following precautions must be observed:

Only mount undamaged, clean, dry rims and tyres that are in good condition.

Remove old balance weights.

Check rim and tyre for damage, especially aluminium rims. Do not mount if damaged.

Check that the rim and tyre size match.

Before dismantling, let all air out of the tyre.

Before mounting, coat the rim and tyre well with tyre lubricant to avoid damage.

Always use a new valve.

The tyre changer is not splash-proof, so do not clean wheels on the machine with water jets.

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-01

Manufacturer ATH-Heinl GmbH & CO.KG

- 7 -

1.3.3. Operating the tyre mounting machine

This instruction manual only details the function of the machine, it does not replace professional training

and qualification of operating personnel.

WARNING!!

All tyre changers have movable or adjustable controls. It is essential to ensure

that the operator finds a working position where he can safely track and view

all work steps.

We have provided videos online that offer assistance in using the machine:

Link: https://www.youtube.com/watch?v=DwEDbsz6PAA

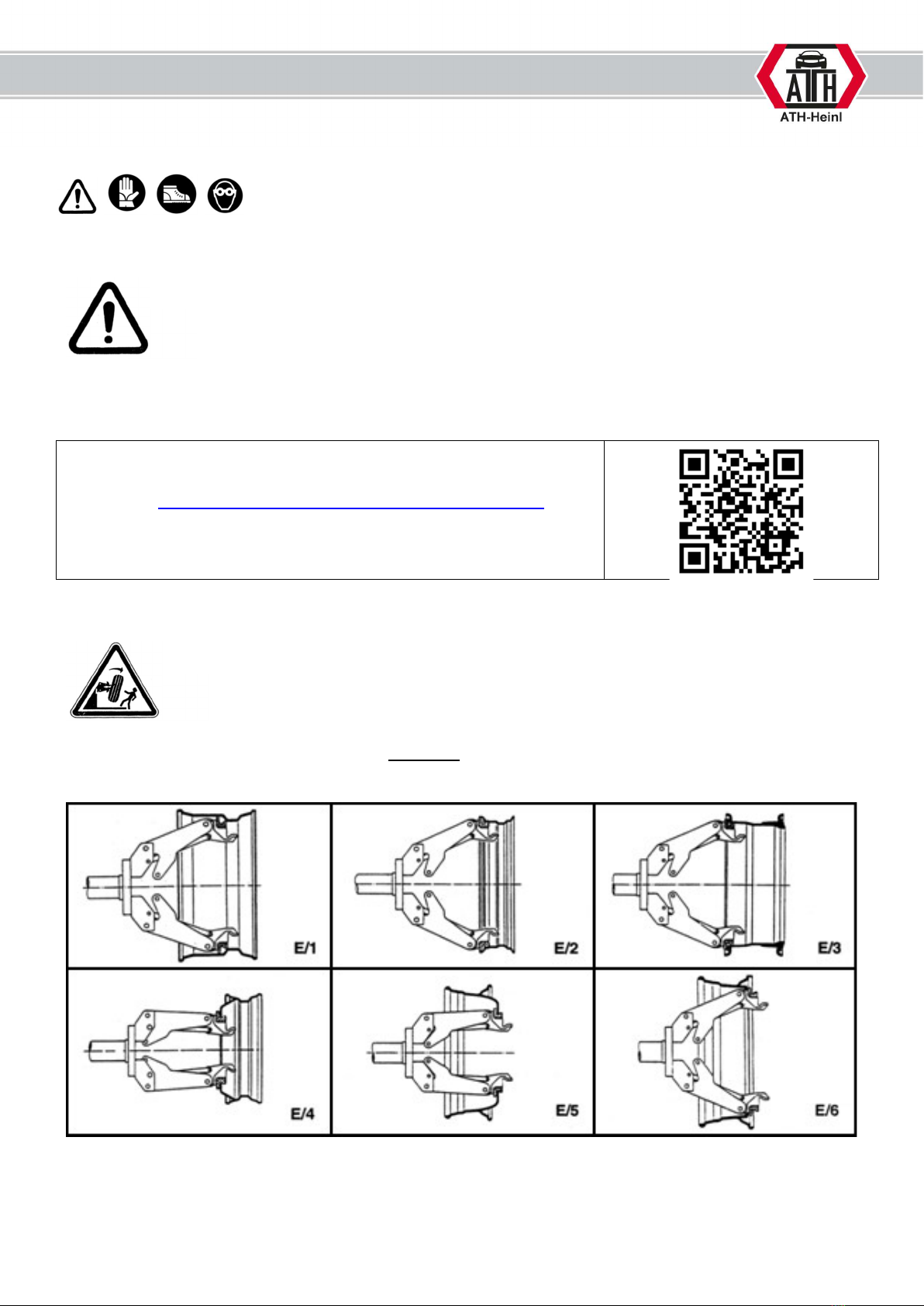

1.3.4. Clamping the wheel

WARNING!!

When tightening the rim, make sure that the clamping jaws are correctly

positioned on the rim to prevent the wheel from falling down.

There are different types of truck rims (Fig. 8 E/1-E6).

Use the four clamping jaws to select the appropriate clamp for the rim.

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-01

Manufacturer ATH-Heinl GmbH & CO.KG

- 8 -

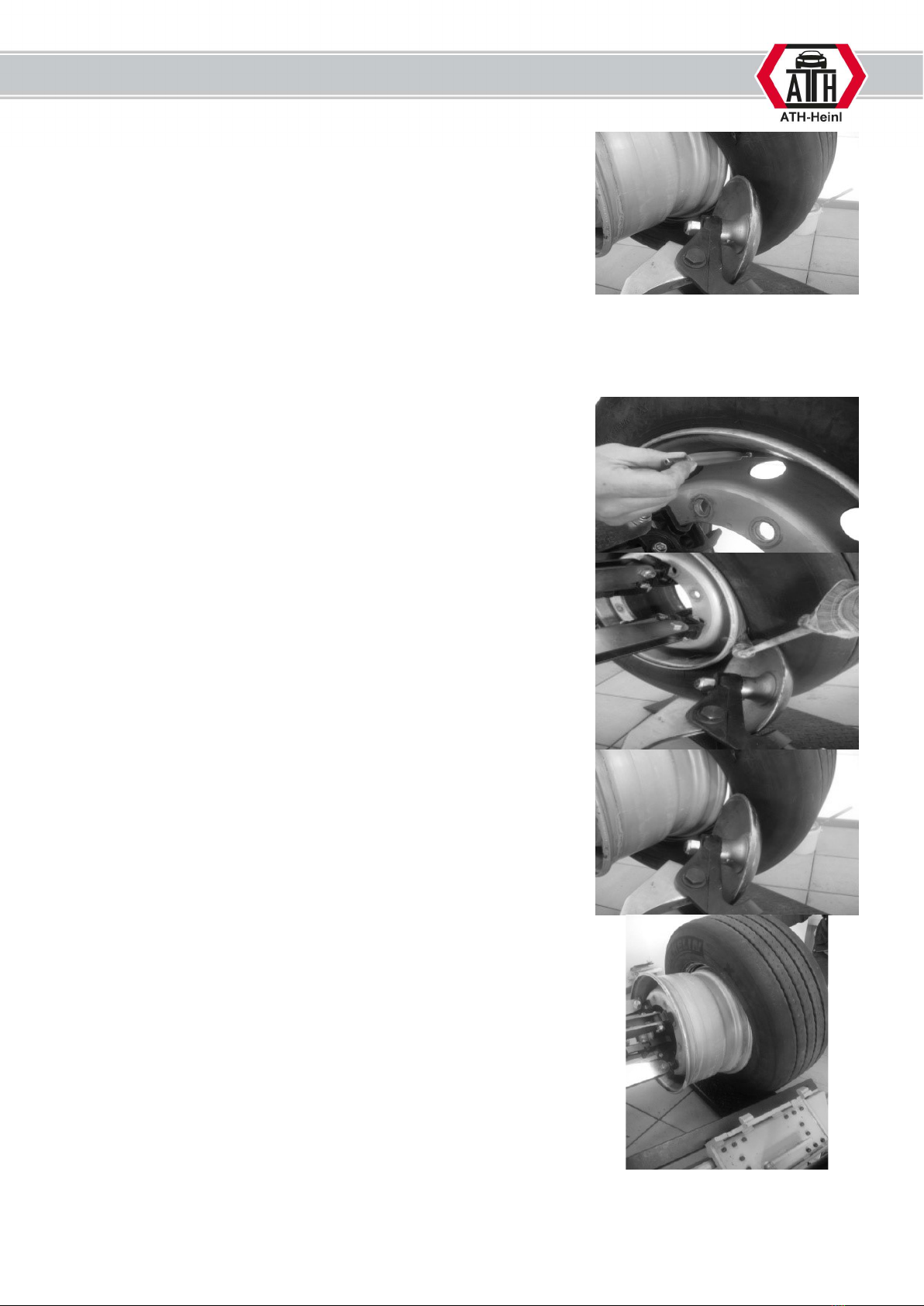

Place the tyre on the inside of the table for the mounting arm.

Continue moving the table until just before the clamping jaws.

Lower the clamping head to the centre of the rim.

Open the clamping jaws until they are smaller than the diameter of the mounting hole.

Slide the tyre over the clamping jaws and open until the tyre is tight.

Check that the rims sit correctly in all four jaws and that the tyre turns smoothly, otherwise it is not

possible to assemble.

WARNING!!

Note that the most secure tension is always at the inner hole.

WARNING!!

Never leave the work area while the wheel is still raised or tensioned.

1.3.5. Removing a tyre

Use the valve driver to let the air out of the tyre.

The tyre bead must first be completely pressed off from both sides

of the rim with the mounting plate. During this process, the

mounting paste is applied to the rim and the tyre bead.

The first bead with rim mounting hook is now mounted.

Feed the mounting hook between the bead and the rim.

The tyre is then levered over the rim by lowering the rim and

pulling the mounting hooks.

Turn counterclockwise to remove the bead.

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-01

Manufacturer ATH-Heinl GmbH & CO.KG

- 9 -

Now remove the second bead with the bead breaker.

1.3.6. Removing a tyre with just a bead breaker

The tyre bead can be dismantled by pulling on most wheels.

Use the valve driver to let the air out of the tyre.

Pull apart both beads and apply plenty of tyre bead lubricant.

The tyre can then be jacked apart from the inside out with the

mounting plate.

Before the tyre is completely removed, remove the mounting plate

and move the rim down so that the tyre is pushed over the rim.

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-01

Manufacturer ATH-Heinl GmbH & CO.KG

- 10 -

WARNING!!

If the tyre is pushed over the second shoulder, it may fall off. Take

appropriate precautions.

1.3.7. Mounting a tyre

Generously apply tyre bead lubricant to the rim and tyre.

The first bead is mounted by pushing in and turning the rim.

The second bead is mounted with the bead retaining clip. A

mounting plate can be used on several tyres.

Install the tyre clamp at the 6 o'clock position and mount it with the

mounting disc. This is a simple and straightforward mounting.

Table of contents

Other ATH Tyre Changer manuals

Popular Tyre Changer manuals by other brands

Coats

Coats 80C operating instructions

HENNESSY INDUSTRIES

HENNESSY INDUSTRIES Coats Rim Clamp X-Model Series instructions

Draper

Draper 78612 user manual

Aston Global

Aston Global ATC-5800 Installation, Operation and Maintenance User’s Manual

HENNESSY INDUSTRIES

HENNESSY INDUSTRIES Coats CHD-4730-4730W Operating and maintenance instructions

Butler

Butler NAV11N instruction manual